Integrated system for dust-removal and desulfurizing

A technology of dust removal device and desulfurization device, which is applied to chemical instruments and methods, use of liquid separation agent, separation of dispersed particles, etc., can solve problems such as difficult operation, poor effect, secondary pollution, etc., and achieve low operating cost and occupy an area The effect of small size and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

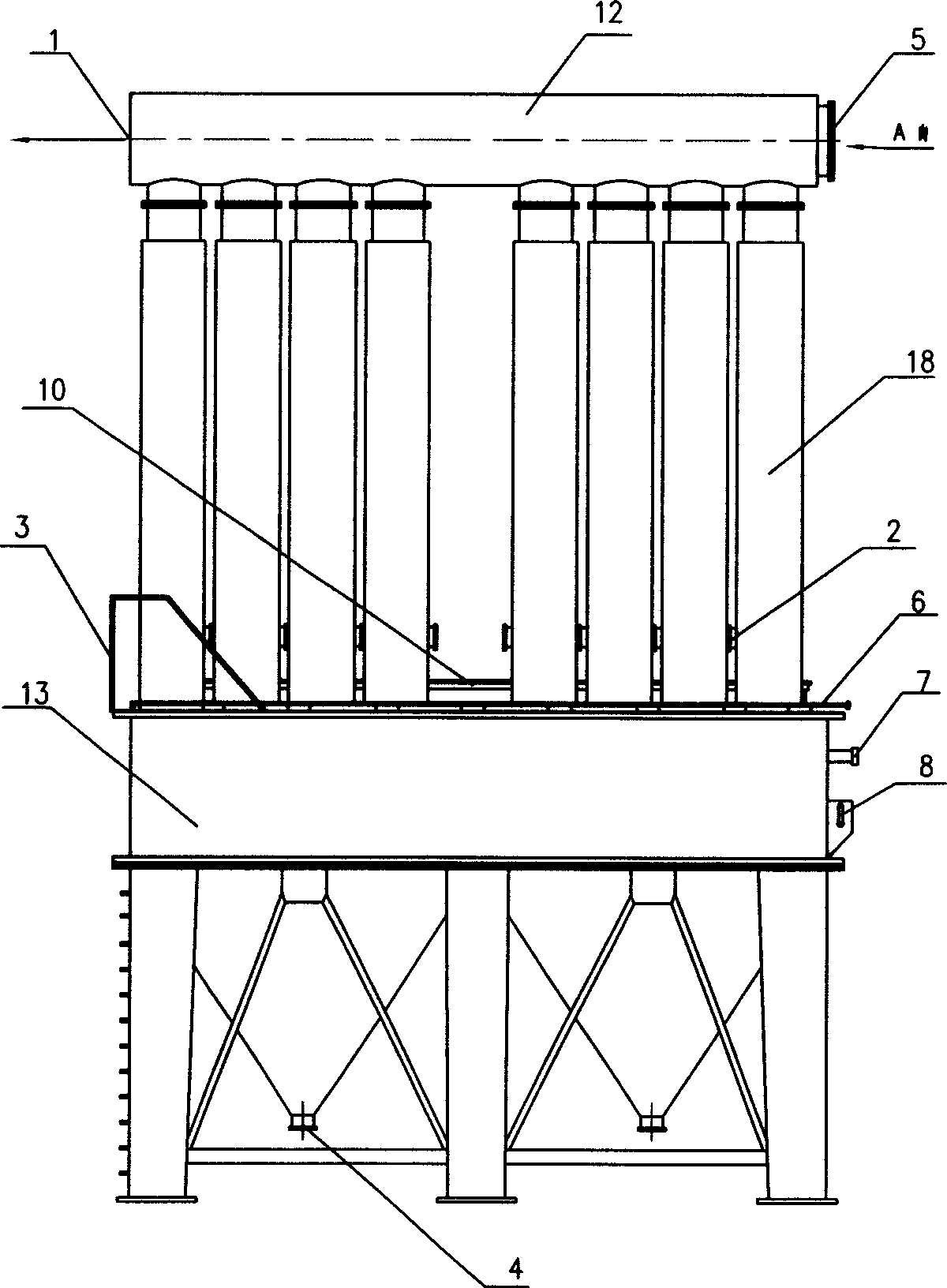

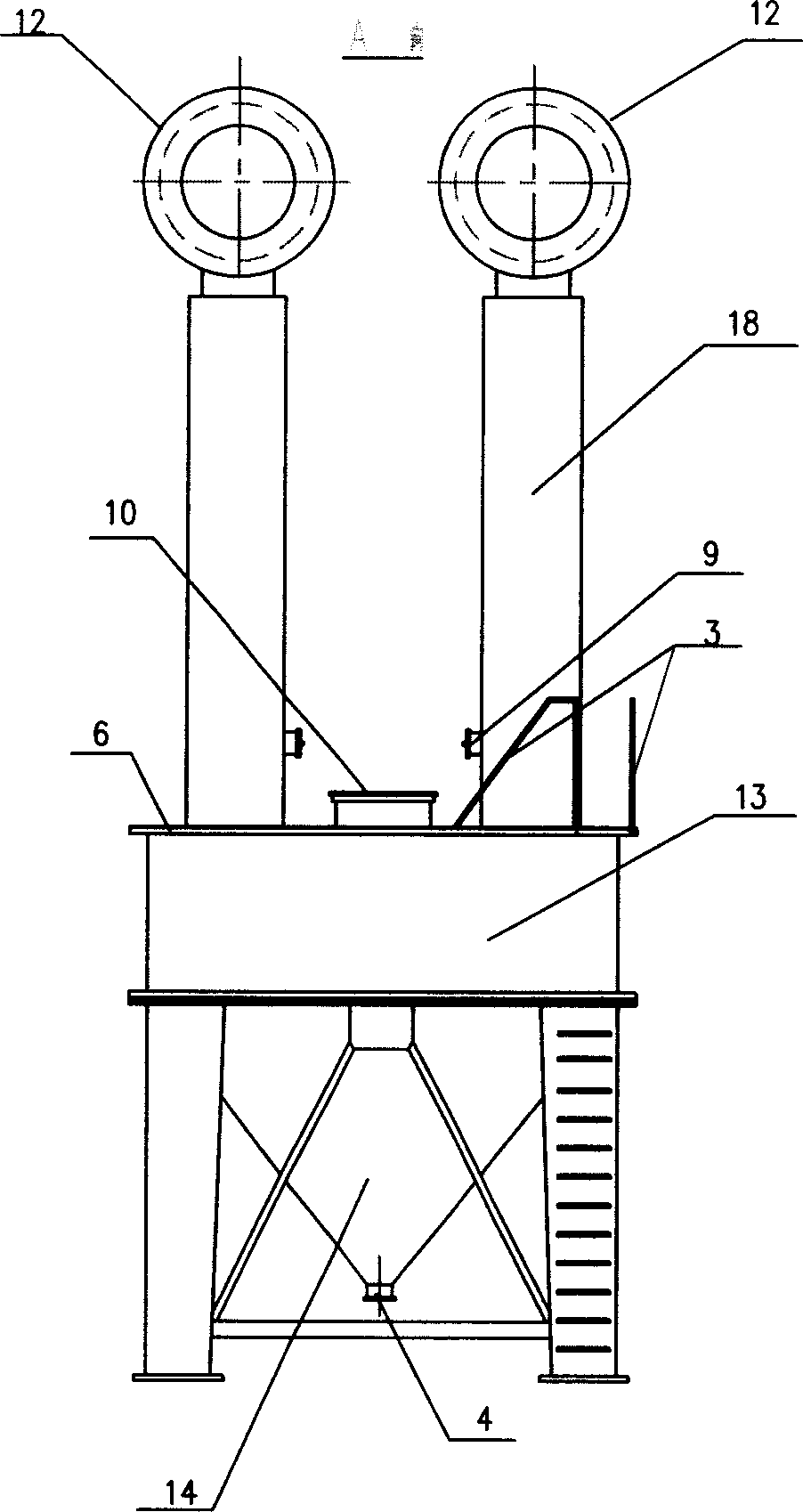

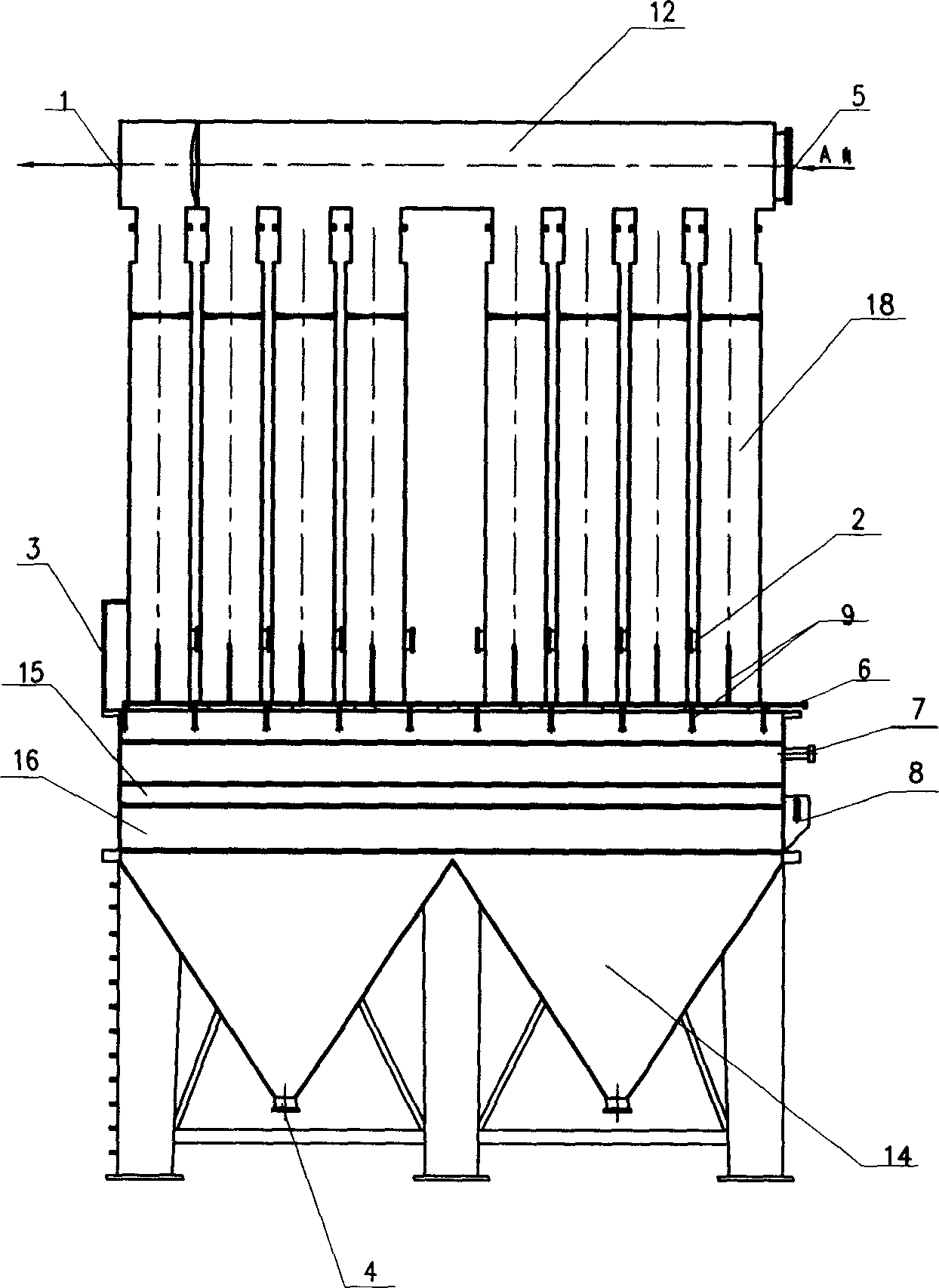

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings. The dust removal and desulfurization integrated system as shown in the figure includes a dust removal device 13, a desulfurization device 11, a dehydration and demisting device 12 and a circulating spray device 6, wherein the dehydration and demisting device 12 is located at The uppermost part of the system is a horizontal cylinder, and a purified gas outlet 1 and a maintenance manhole 5 are respectively arranged on both sides of the cylinder, so that the purified gas can be discharged into the nature and easy to maintain. A demister 21 is provided, and the demister 21 in the dehydration and demister device 12 is a swirl plate demister; the desulfurization device 11 includes 16 desulfurization cylinders 18, and a dehydrator 20 is arranged in the desulfurization cylinder, and on the outer wall of the desulfurization cylinder 18 Hand hole 2 is arranged on it.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com