Dual-tower dust removal and desulphurization device

The technology of a desulfurization device and main tower is applied in the directions of using liquid separating agent, lighting and heating equipment, and dispersed particle separation, etc., which can solve the problems of low dust removal and desulfurization efficiency, high operating cost and high cost, and achieves high dust removal and desulfurization efficiency. The effect of low operating cost and good environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

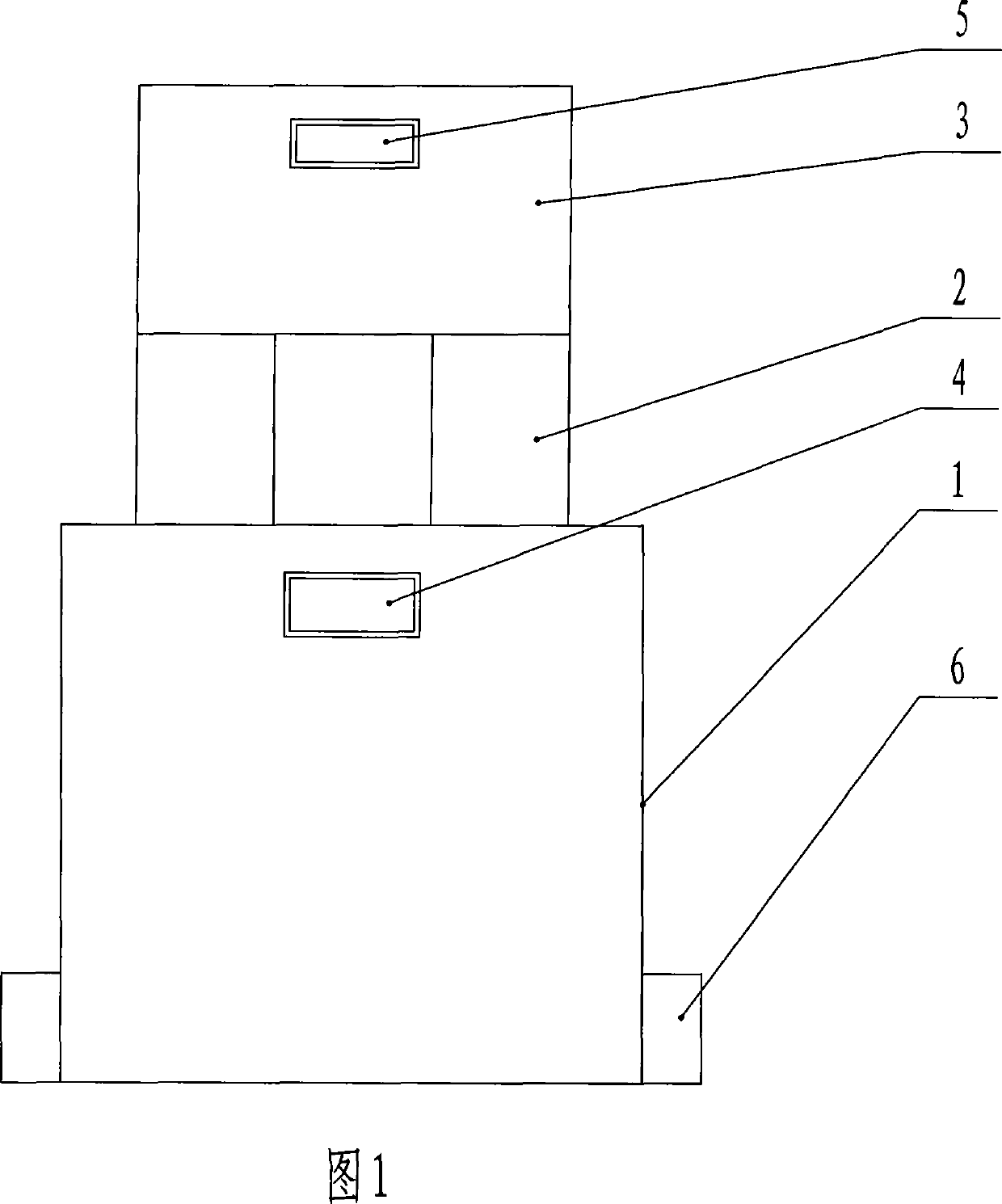

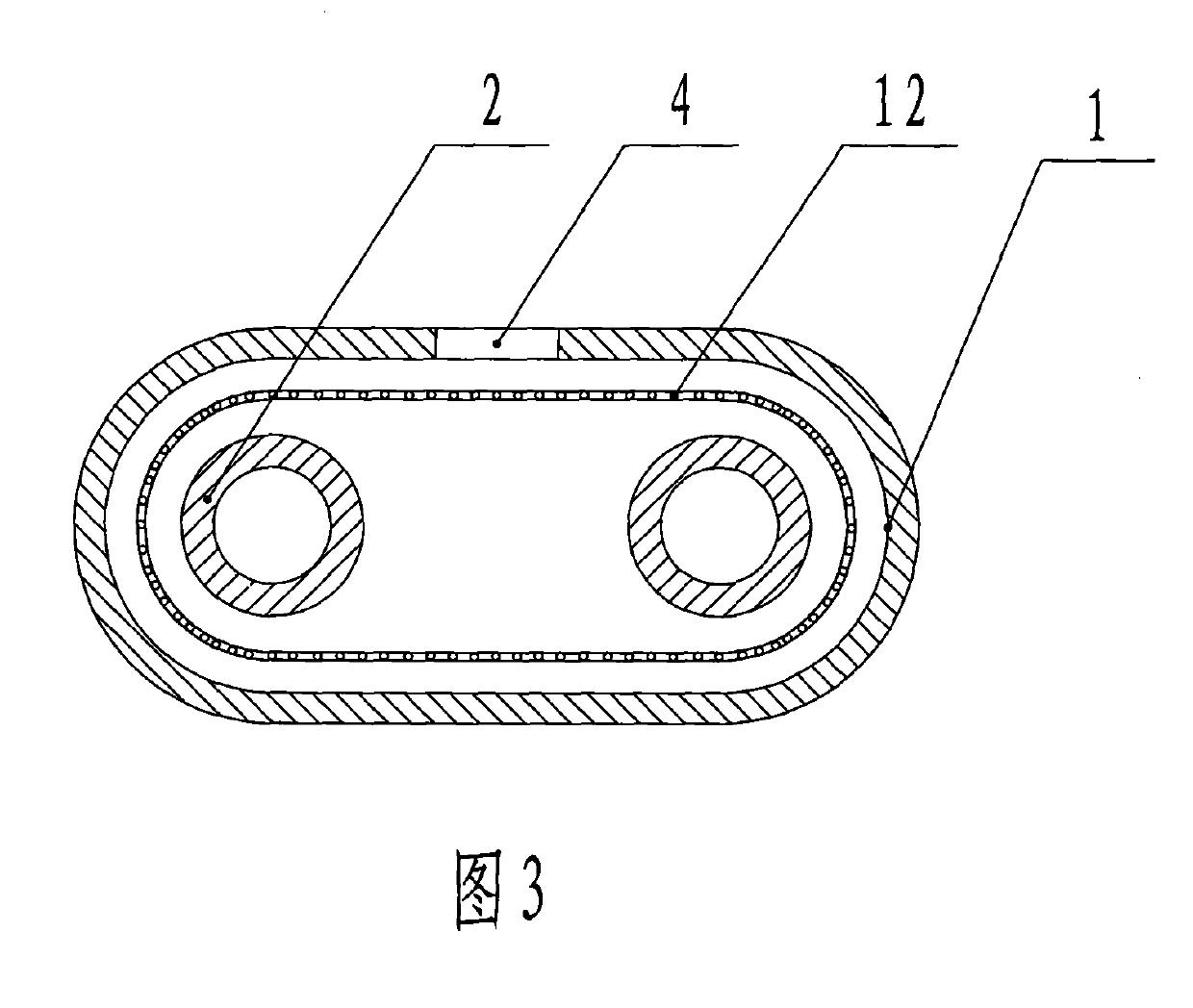

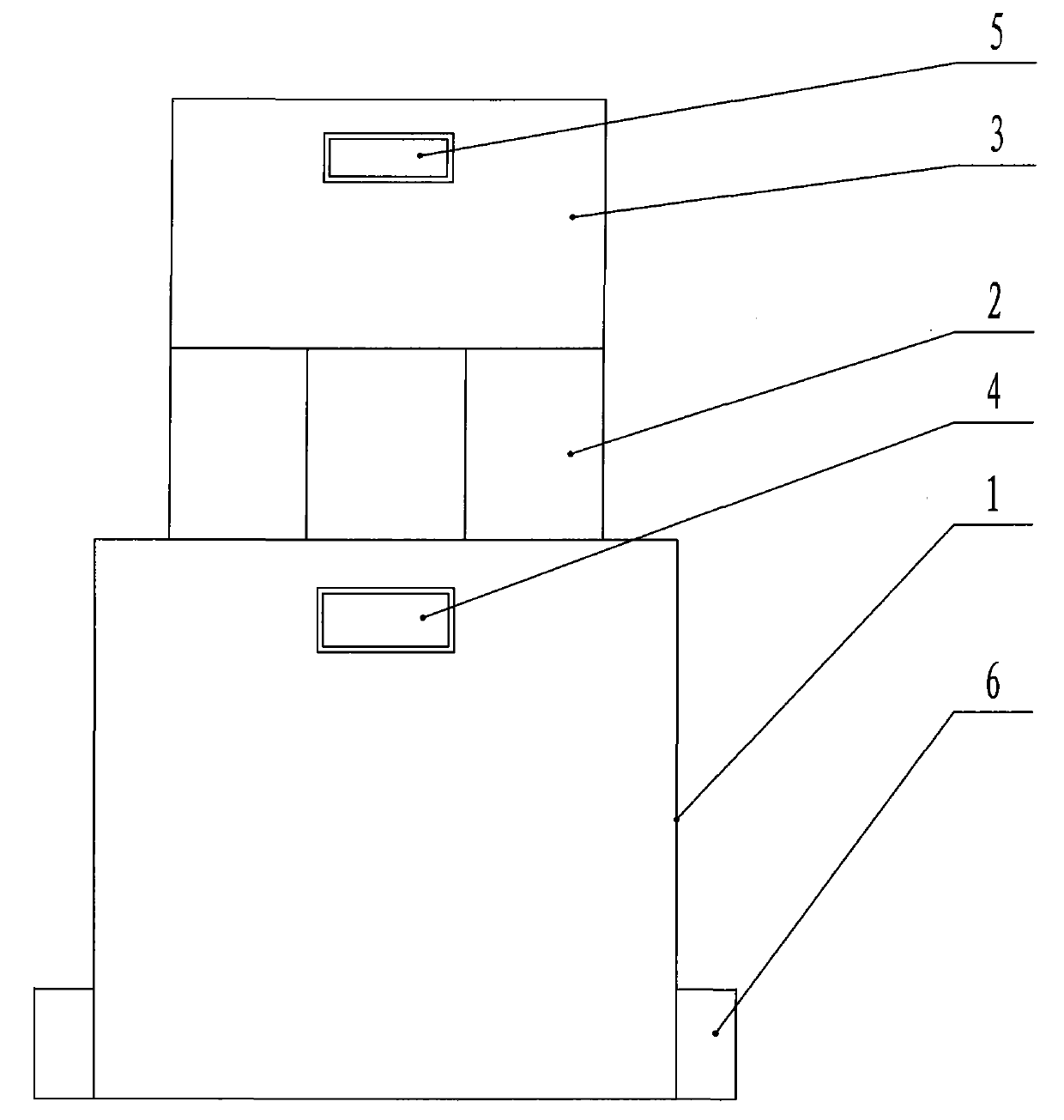

[0009] Such as figure 1 , figure 2 , image 3 As shown, a double-tower dedusting and desulfurization device includes a main tower 1. There is a flue gas inlet 4 on the main tower 1. There is a sprayer 12 on the top side of the main tower 1. The upper end of the main tower 1 is closed, and the lower end has a drain hole. 6. The twin towers 2 are inserted into the inner bottom of the main tower 1 from the upper end of the main tower 1, and a communication hole 7 is opened to communicate with the main tower 1, and the upper end of the twin towers 2 is connected to the top tower 3, and the twin towers 2 are equipped with sub-tower sprinklers 8 and the sub-tower demister 9, the top tower sprayer 11 and the top tower demister 10 are installed in the top tower 3, and the top tower 3 has a flue gas outlet 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com