Dust removal desulfurization multiplier and wet desulfurization device

A wet desulfurization and multiplier technology, which is applied to cyclone devices, separation devices, combined devices, etc., can solve the problems of inability to carry out renovation, long renovation construction period, and high operating costs, and achieves low renovation costs and operating costs, and dust removal. The effect of high desulfurization efficiency and easy engineering transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

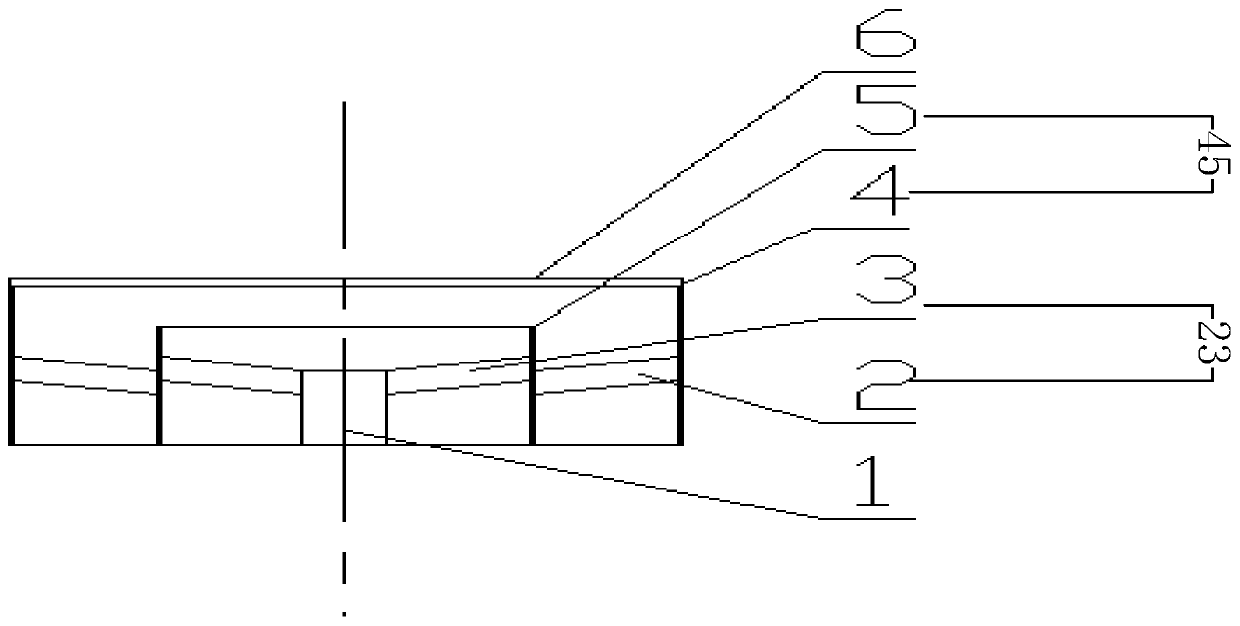

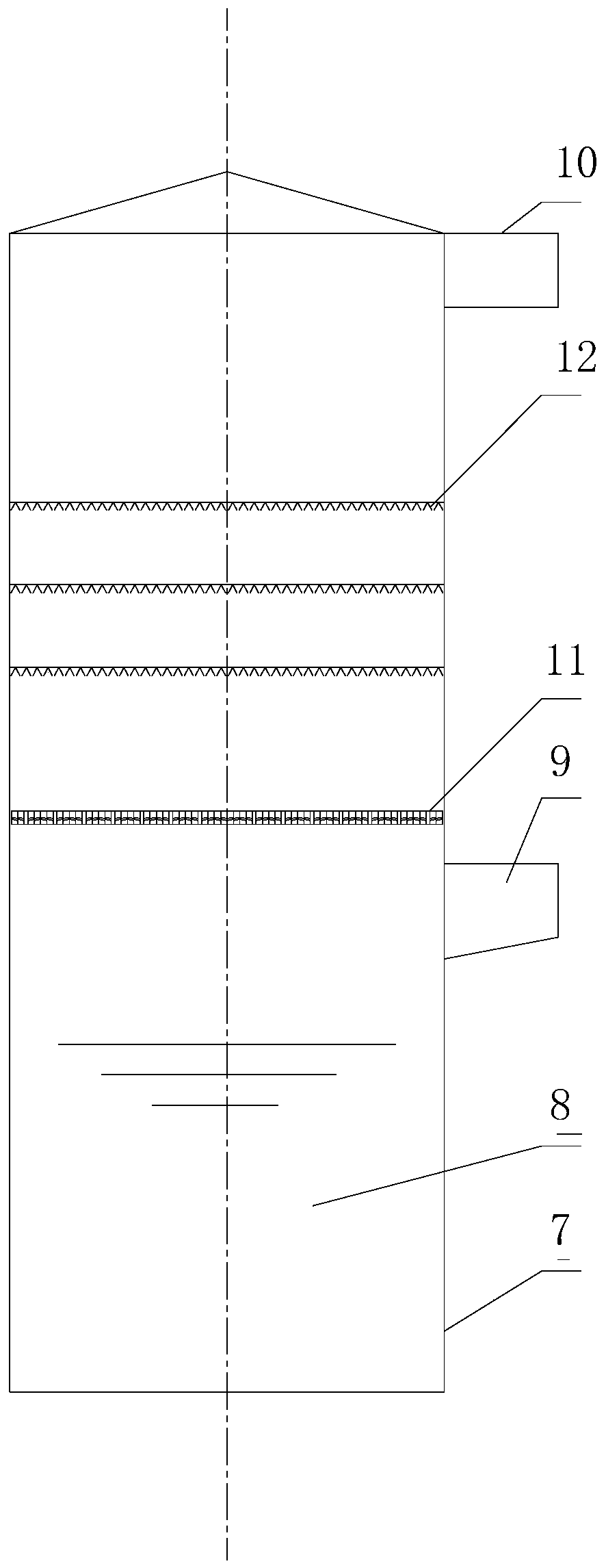

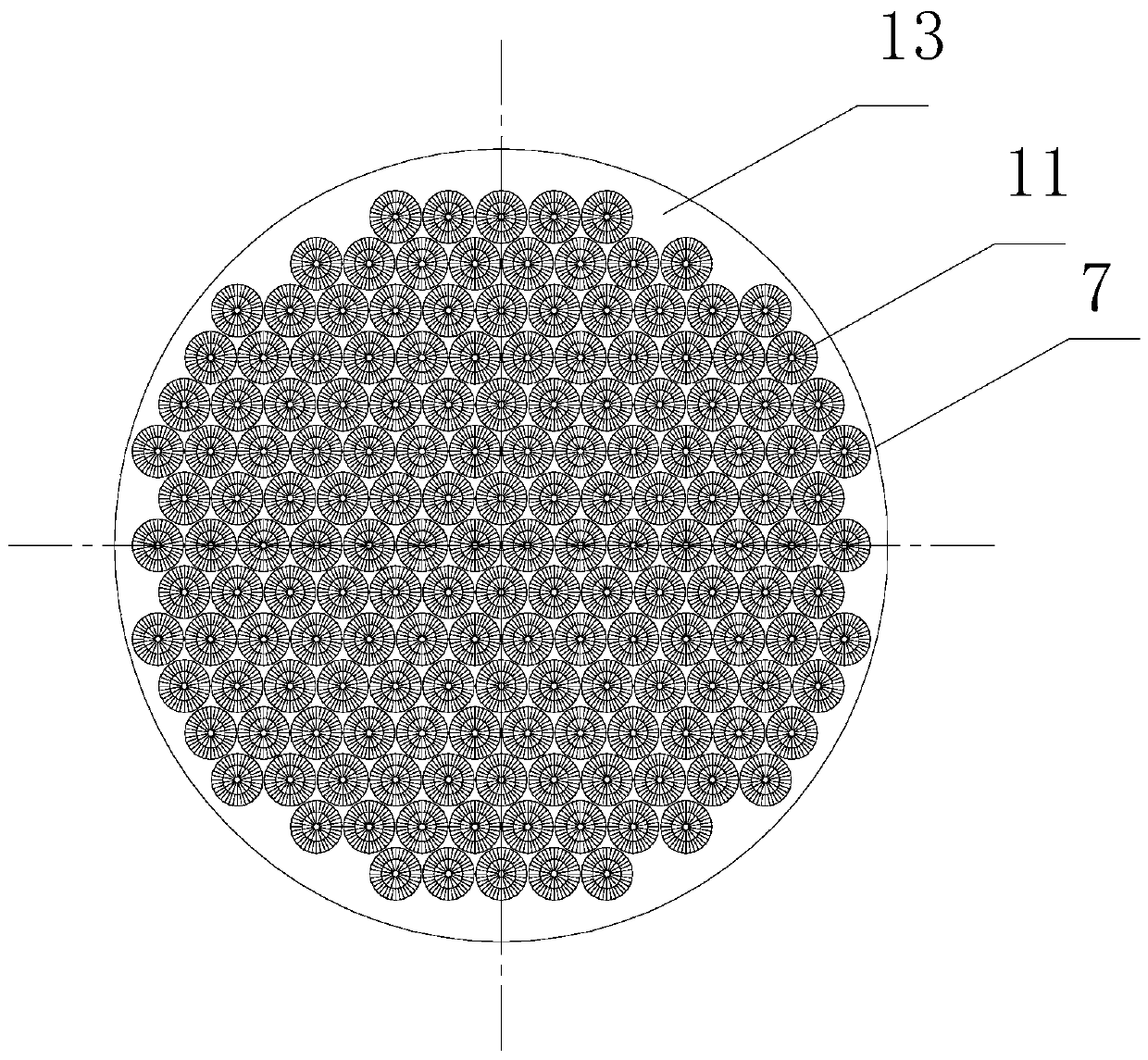

[0023] The present application includes a cyclone cylinder, and a blind cylinder arranged inside the cyclone cylinder, and cyclone blades are installed on the blind cylinder. A sieve plate with a preset opening ratio is set above the cyclone cylinder. When the flue gas passes through the dust removal and desulfurization booster, gas-liquid impact and rotational flow will occur between the cyclone blades and the wall of the cyclone cylinder. The sieve keeps the droplets trapped within the cyclone. Therefore, in this application, due to the violent collision between the slurry and the flue gas in the relatively closed space between the cyclone cylinder and the sieve plate, a stronger mass transfer effect can be produced, and at the same time, dust and liquid droplets can be effectively prevented from splashing out of the cyclone cylinder. The dust removal and desulfurization efficiency of the present application is high, and it is convenient for engineering transformation, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com