Basket-free type strand machine

A strand rope machine and basket type technology, which is applied in the field of strand rope production equipment, can solve the problems of reducing the quality of steel wire rope, high labor intensity, and large rotational load, and achieve the effects of simple structure, reduced labor intensity, and small dynamic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

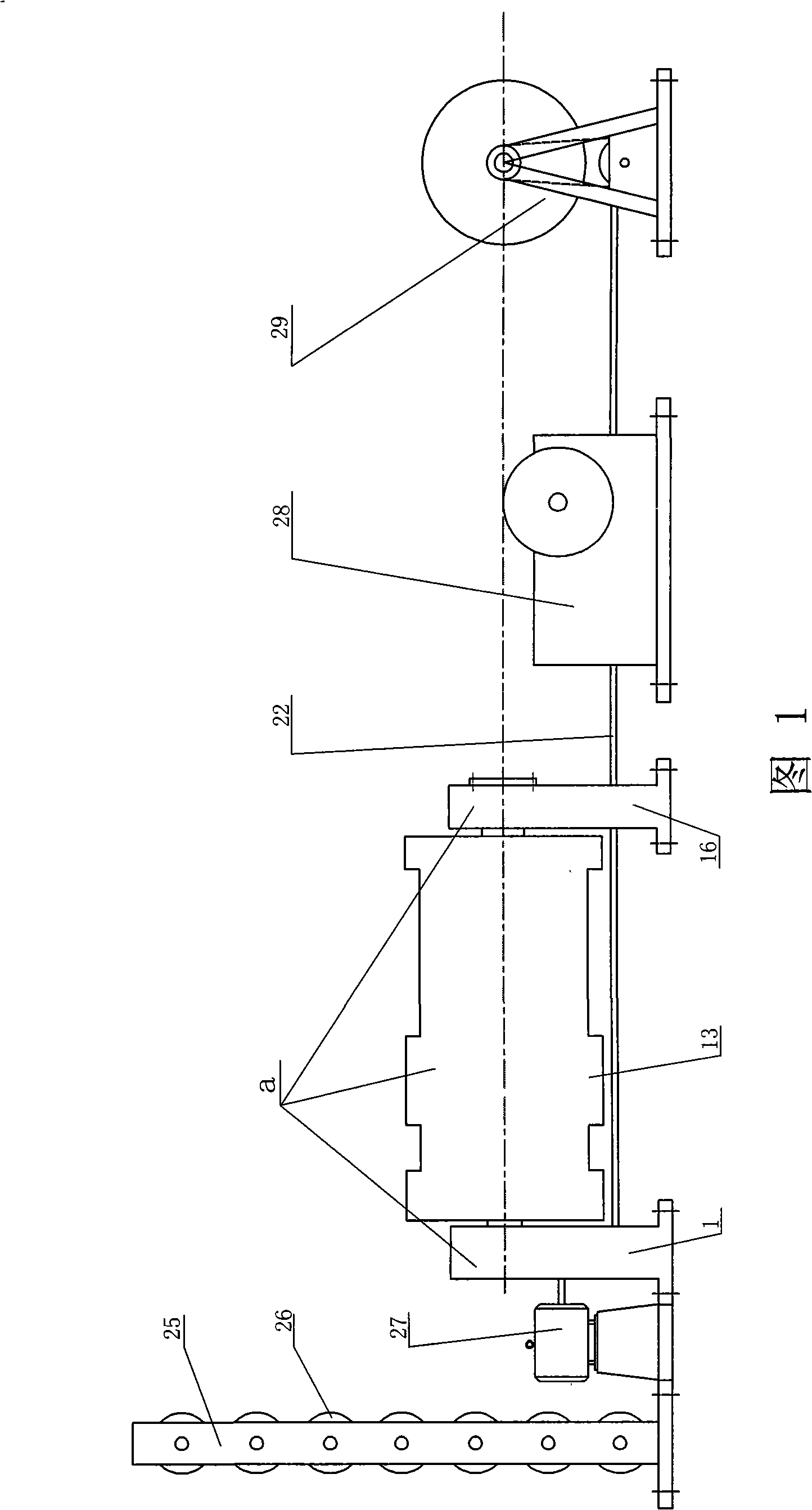

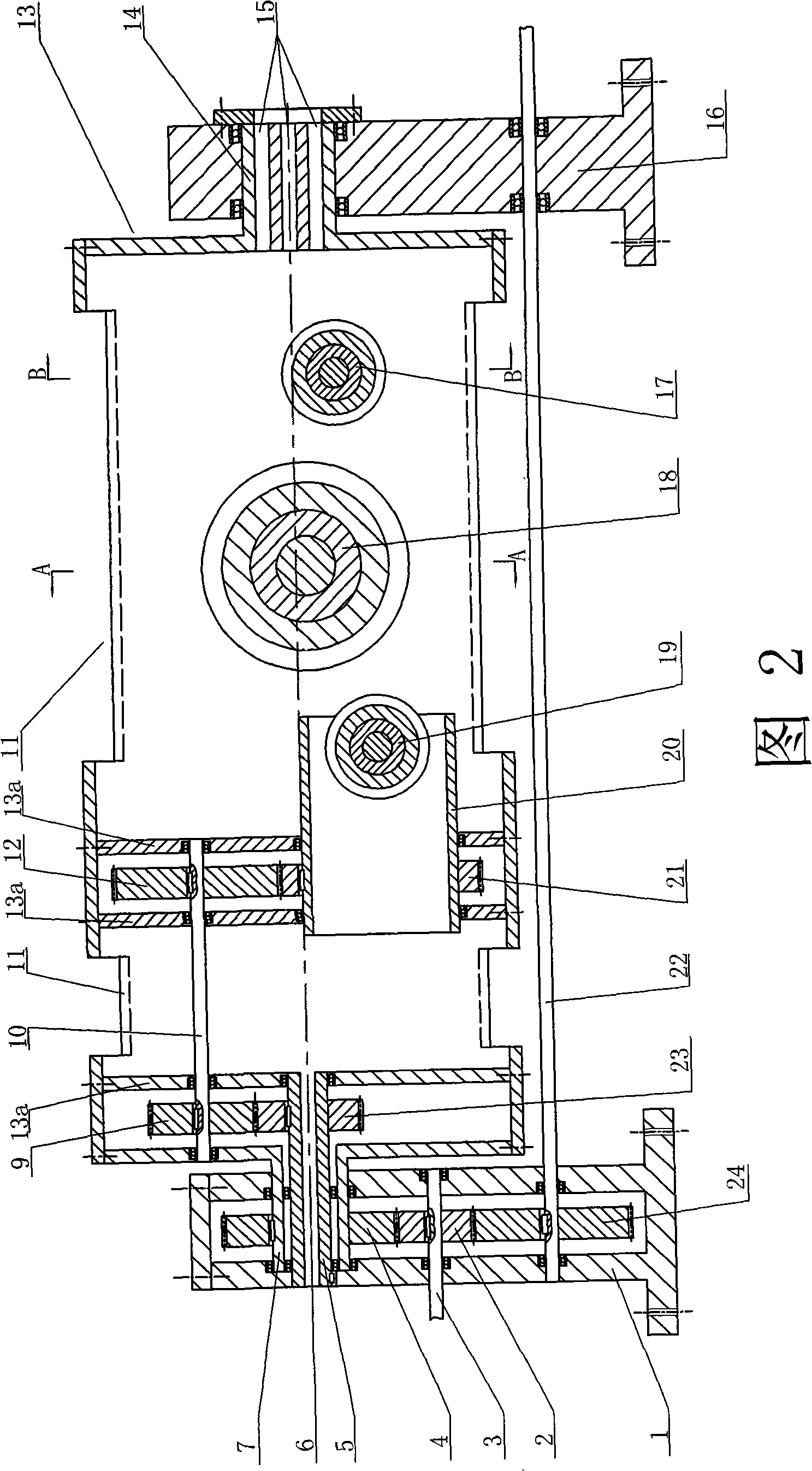

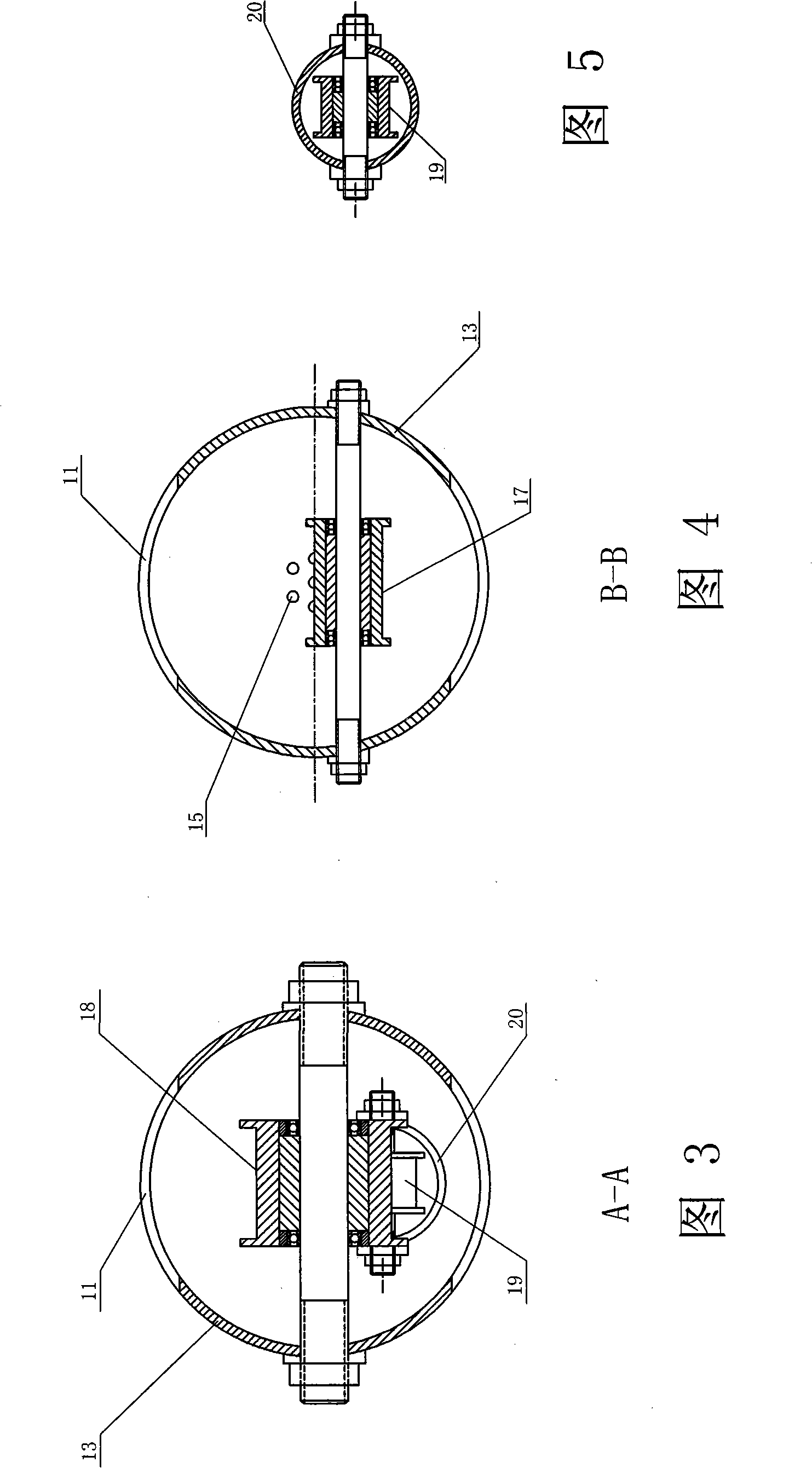

[0024] This non-basket-type strand rope machine includes a motor 27, a pay-off frame 25, a traction transmission shaft 22, a drum device a, a traction device 28, and a take-up device 29; Wherein drum device a comprises left and right bracket and drum 13, and left bracket 1 li is provided with gear box, and the shaft of above-mentioned motor 27 is connected with the main transmission shaft 3 in this gear box; The left and right end faces are solidly integrated, bearings are respectively installed on the left and right end shafts, and the outer rings of the bearings are respectively installed on the left and right brackets to realize the rotational connection relationship; one end of the traction transmission shaft 22 is connected with the traction transmission gear 24 in the above-mentioned gear box Connect, and the other end is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com