Electro-optical device, method for driving the same, and electronic machine

An electro-optical device, liquid crystal driving technology, applied in electrical components, color TV parts, optics, etc., can solve the problems of difficult driving frequency and lighting period setting, not taking into account color disorder, shortening the liquid crystal voltage holding period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

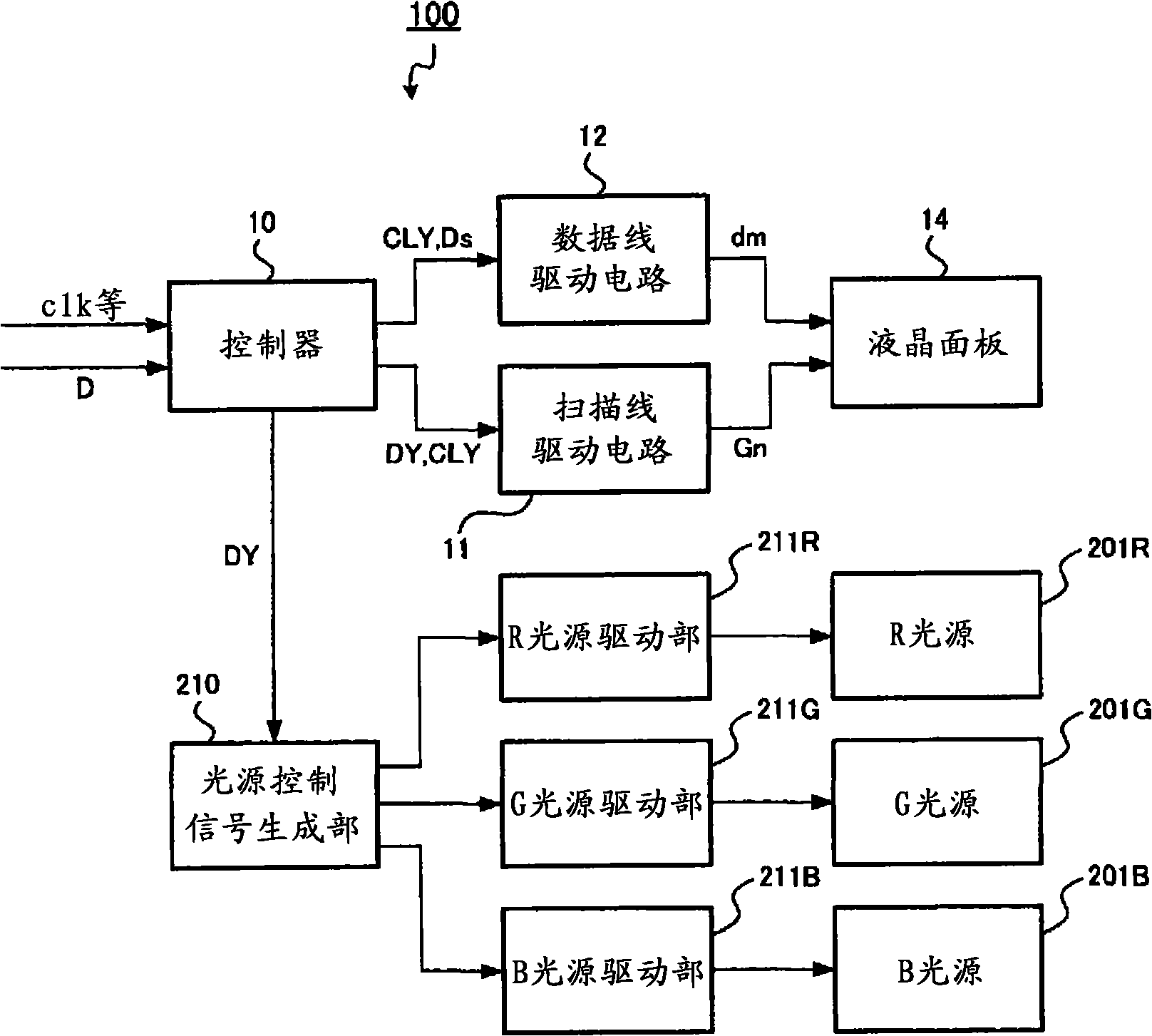

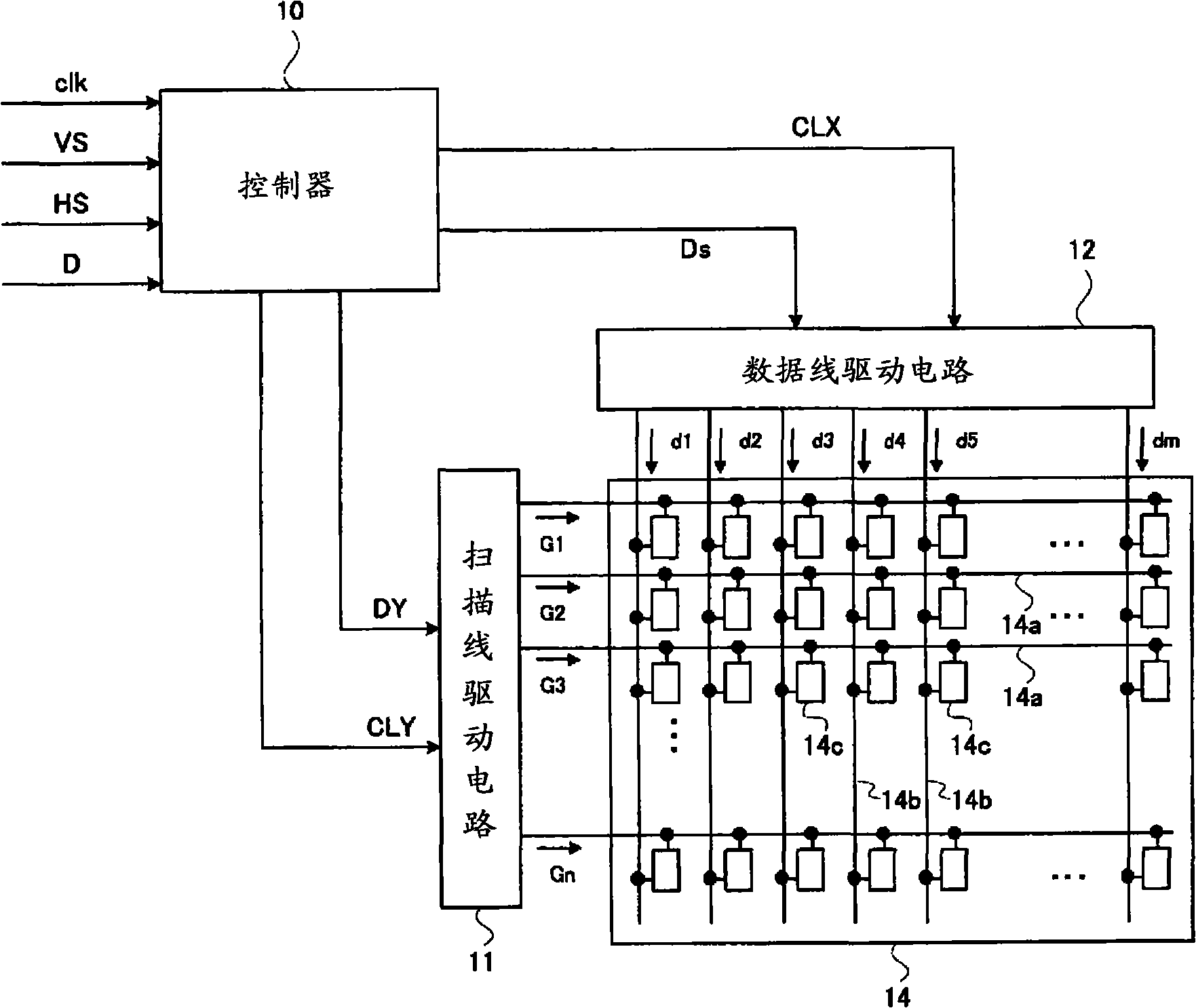

[0061] In the first embodiment, the switching of the light source color is controlled so that the switching period of the light source color is shorter than the period in which the liquid crystal 14g of the pixel 14c constitutes a gradation. That is, in the first embodiment, subfields using the same light source color are not continued, but are switched to subfields of different light source colors before temporally forming gradations. This corresponds to the case where gray scales are formed by making the light source emit light at an appropriate timing while suppressing the driving of the liquid crystal panel 14 as much as possible. As a result, color breakup due to color sequential driving can be suppressed, and good color rendering and gradation characteristics can be realized.

[0062] In addition, such switching control of light source colors is mainly performed by the light source control signal generation unit 210 in the above-mentioned drive circuit 100 . Specificall...

no. 2 Embodiment approach

[0074] Next, the light source control method of the second embodiment will be described. In the second embodiment, like the above-mentioned first embodiment, the switching of the light source color is controlled so that the switching cycle of the light source color is shorter than the cycle in which the liquid crystal 14g constitutes a gradation. However, the second embodiment is different from the first embodiment in that the switching period of the light source color is changed according to the input image signal D. Specifically, in the second embodiment, the average gradation value for each color is obtained from the image signal D, and the switching period of the light source color is changed based on the average gradation value. That is, in the second embodiment, the switching period of the light source color is changed according to the color tendency in the image. In this way, it is possible to effectively suppress the display deterioration caused by the non-response of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com