Pressure change-over device

A conversion device and pressure technology, applied in the direction of osmosis/dialysis water/sewage treatment, reverse osmosis, etc., can solve the problems of large energy loss and waste of energy, and achieve the effects of protecting the environment, reducing waste of resources, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

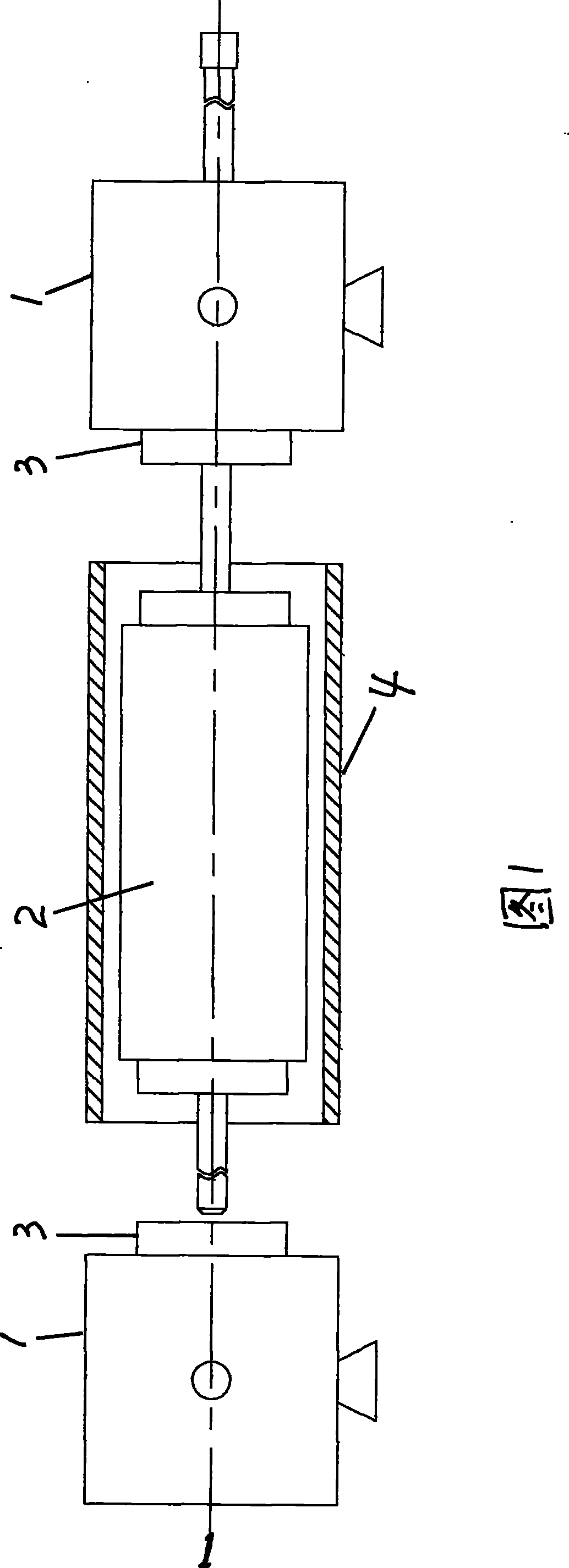

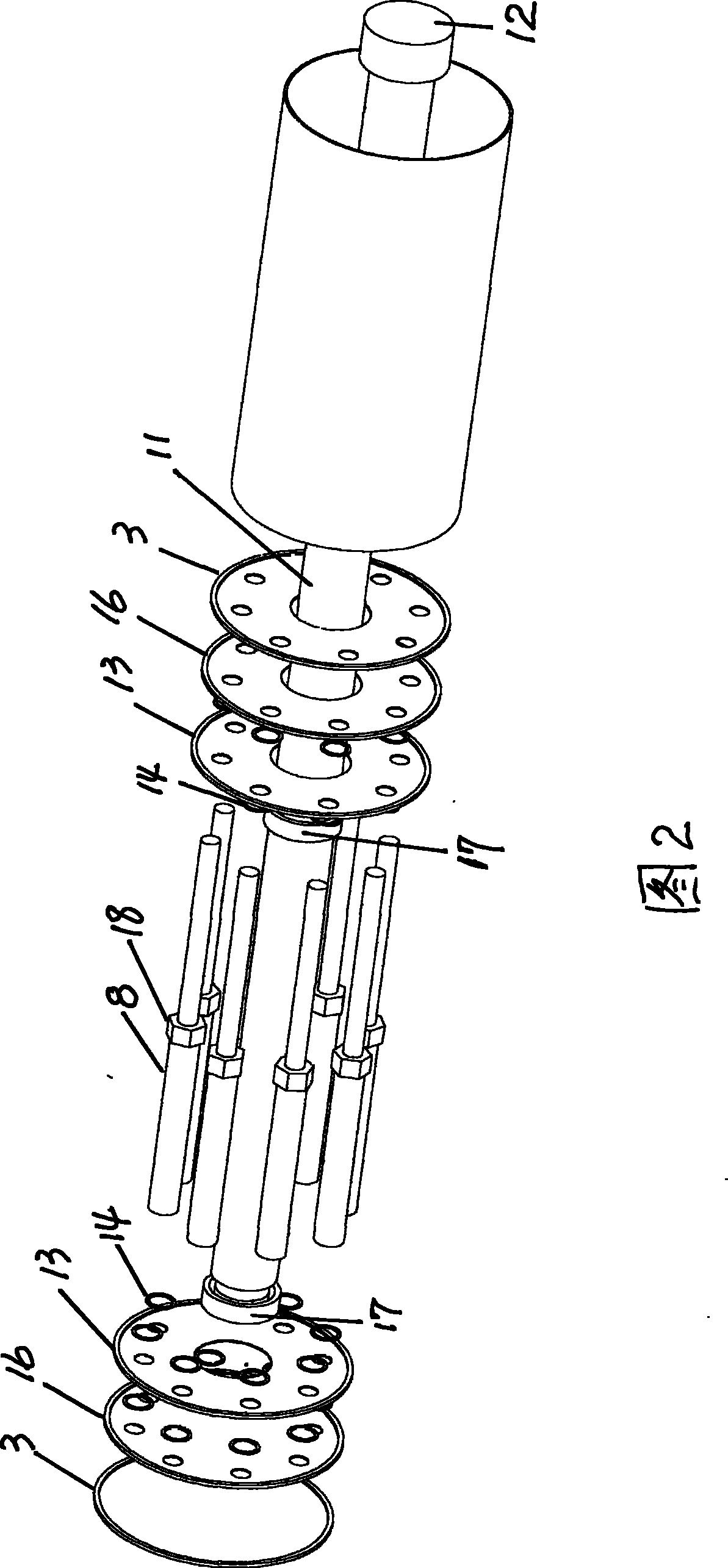

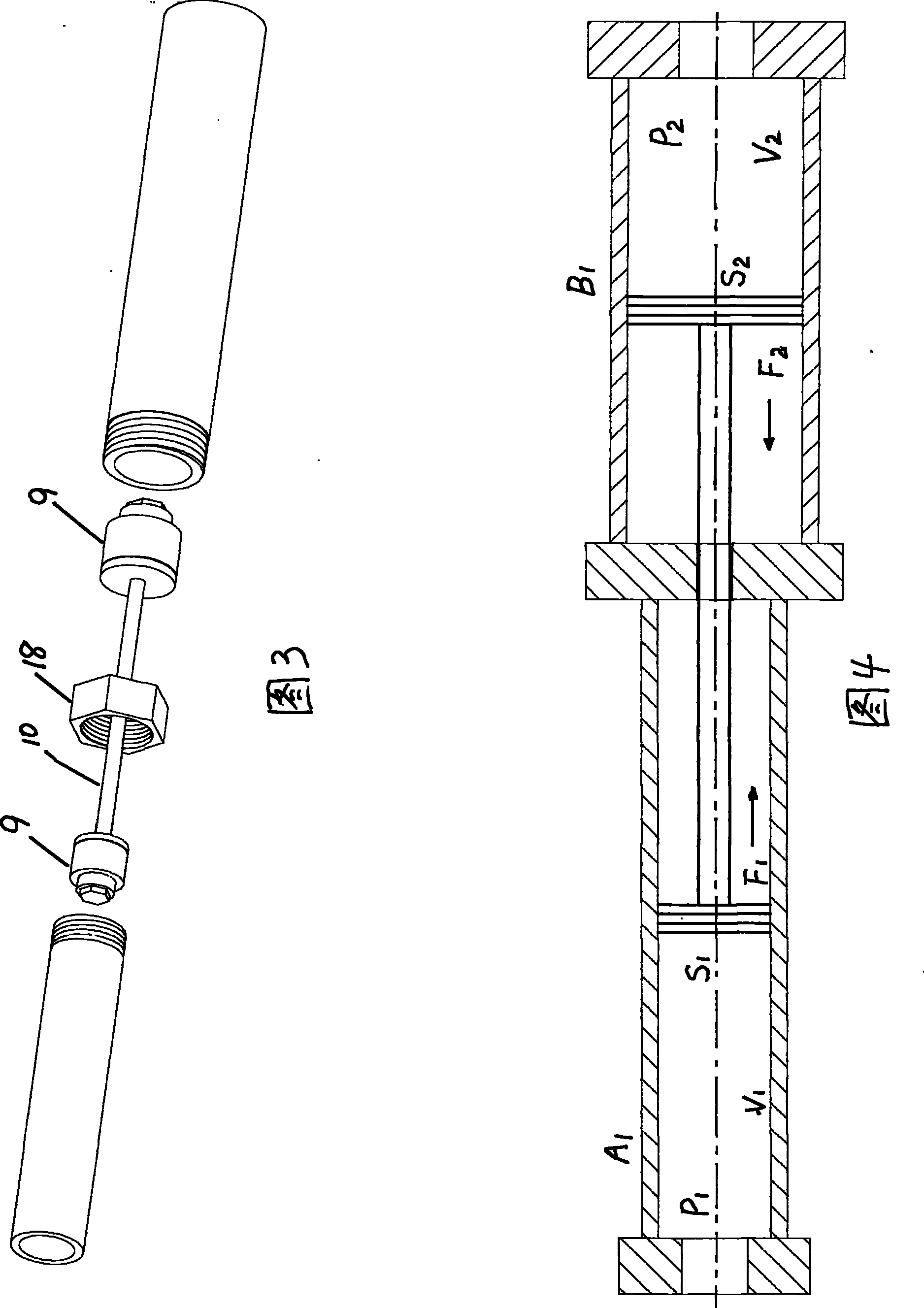

[0017] A pressure conversion device according to the present invention, such as figure 1 , figure 2 , image 3, Figure 6 and Figure 7 As shown, it consists of two fixed end bodies 1 connected with a rotating main body 2 . Wear-resistant ceramic 3 is used for mechanical seal between the fixed end and the rotating body, and other wear-resistant materials can also be used, such as tungsten steel, stainless steel or steel plated with wear-resistant chromium, and then vacuum ion-plated titanium nitride or titanium nitride film, etc. . Between the two fixed end bodies, a cylindrical shell 4 is fixedly connected. The two fixed end bodies 1 are respectively provided with a wear-resistant ceramic 3 , a water inlet 5 , a water outlet 6 and a support seat 7 . The cylinder body 8 is formed by connecting two cylinders with different inner diameters. The inner wall of the cylinder is required to be smooth and wear-resistant, and is equipped with two sealed and slidable terminals 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com