High-frequency off-lining inner burr removing apparatus for straight-line joint electric resistance welding steel tube

A technology of straight seam resistance welding and cleaning device, which is applied in the direction of grinding machines, grinding machine parts, abrasives, etc. It can solve the problems of poor precision of internal burrs, difficult internal operations, inconvenient operation, etc., and achieves high precision and wide application range. Wide, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

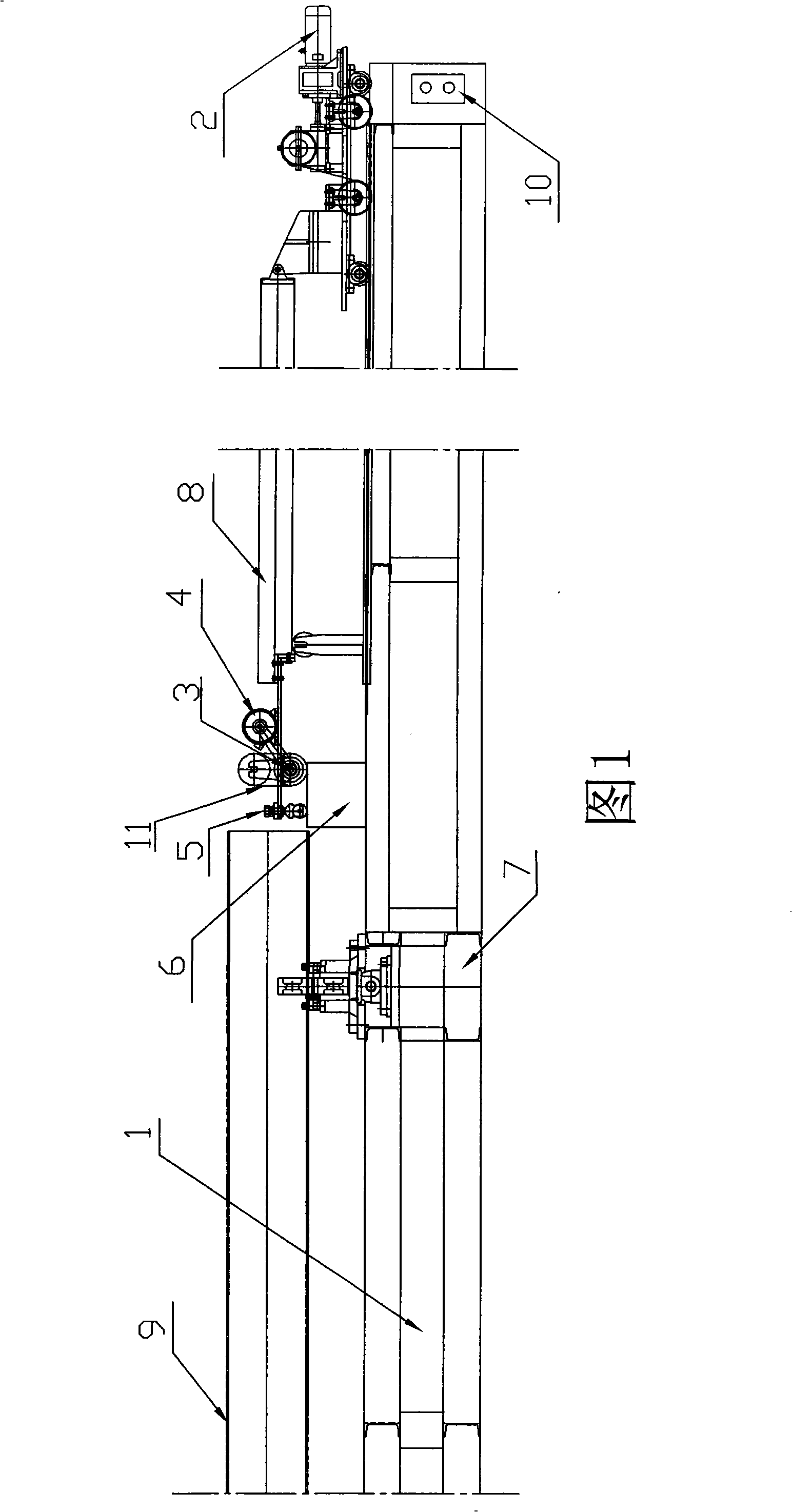

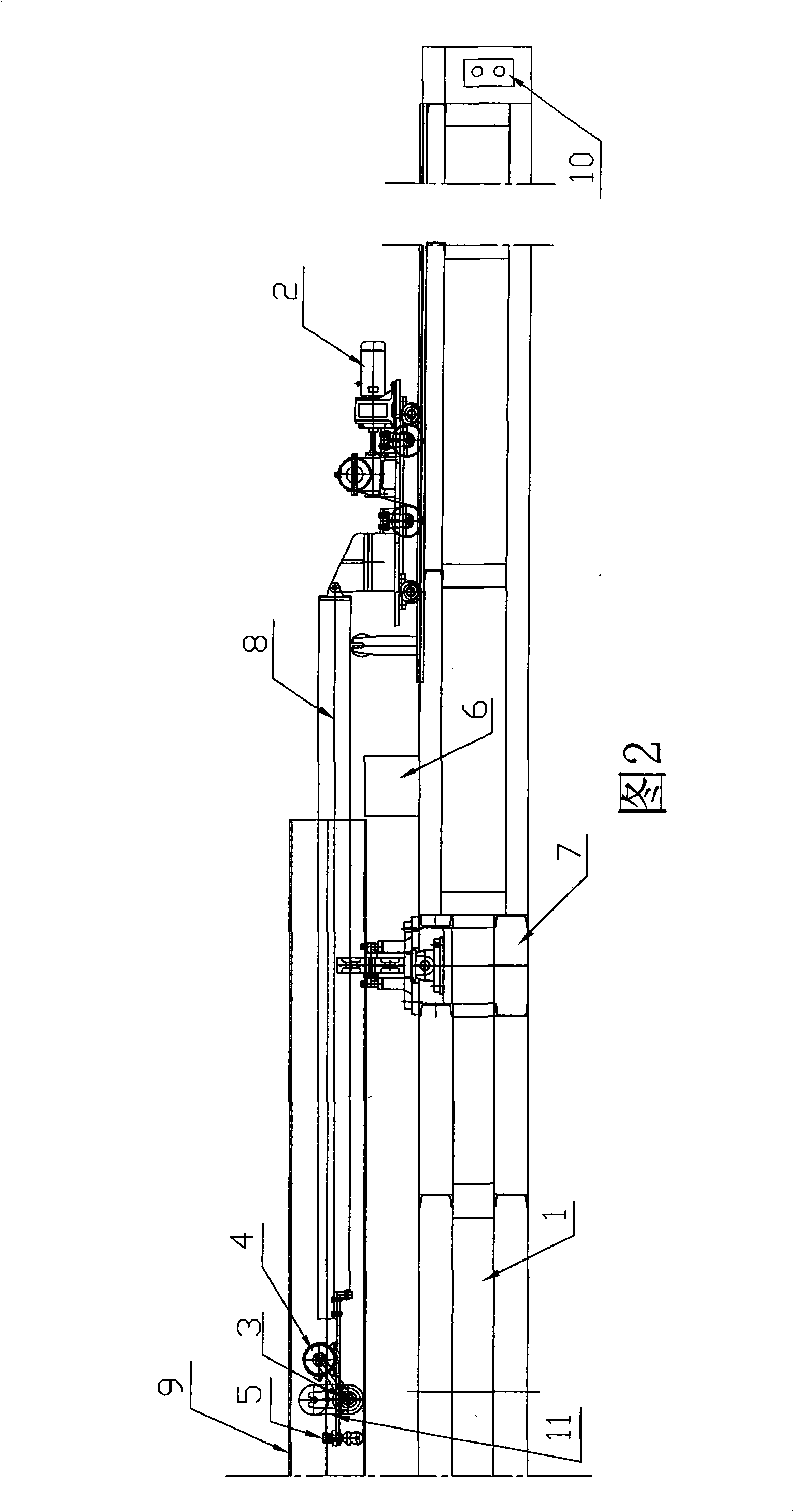

[0015] Fig. 1 is a schematic diagram of the structure of the grinding head outside the steel pipe in the off-line internal burr removal device for high-frequency straight seam resistance welded steel pipes of the present invention; it includes a base 1, a steel pipe fixing device 7, a driving trolley 2, a connecting rod 8 and a grinding head assembly, The steel pipe fixing device 7 is fixed on the base 1 , the driving trolley 2 is set on the base 1 in a walkable manner, and the grinding head assembly and the driving trolley 2 are respectively connected to the two ends of the connecting rod 8 .

[0016] The grinding head assembly includes a grinding head motor 4, a grinding head driving wheel set 3 and a grinding belt 11, the grinding head driving wheel set 3 is connected to the grinding head motor 4, and the grinding belt 11 is connected to the grinding head driving wheel set 3 superior. Grinding head driving wheel pair 3 is 35-40 degrees to the removed internal burr axis, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com