Motorcycle engine piston

A technology for engines and motorcycles, which is applied in the direction of engine components, machines/engines, pistons, etc., can solve the problems of thermal engine noise, high cost, and lack of lubrication in the cylinder head, so as to reduce the inertia of reciprocating motion, reduce noise and abnormal noise, and prolong the life of the engine. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

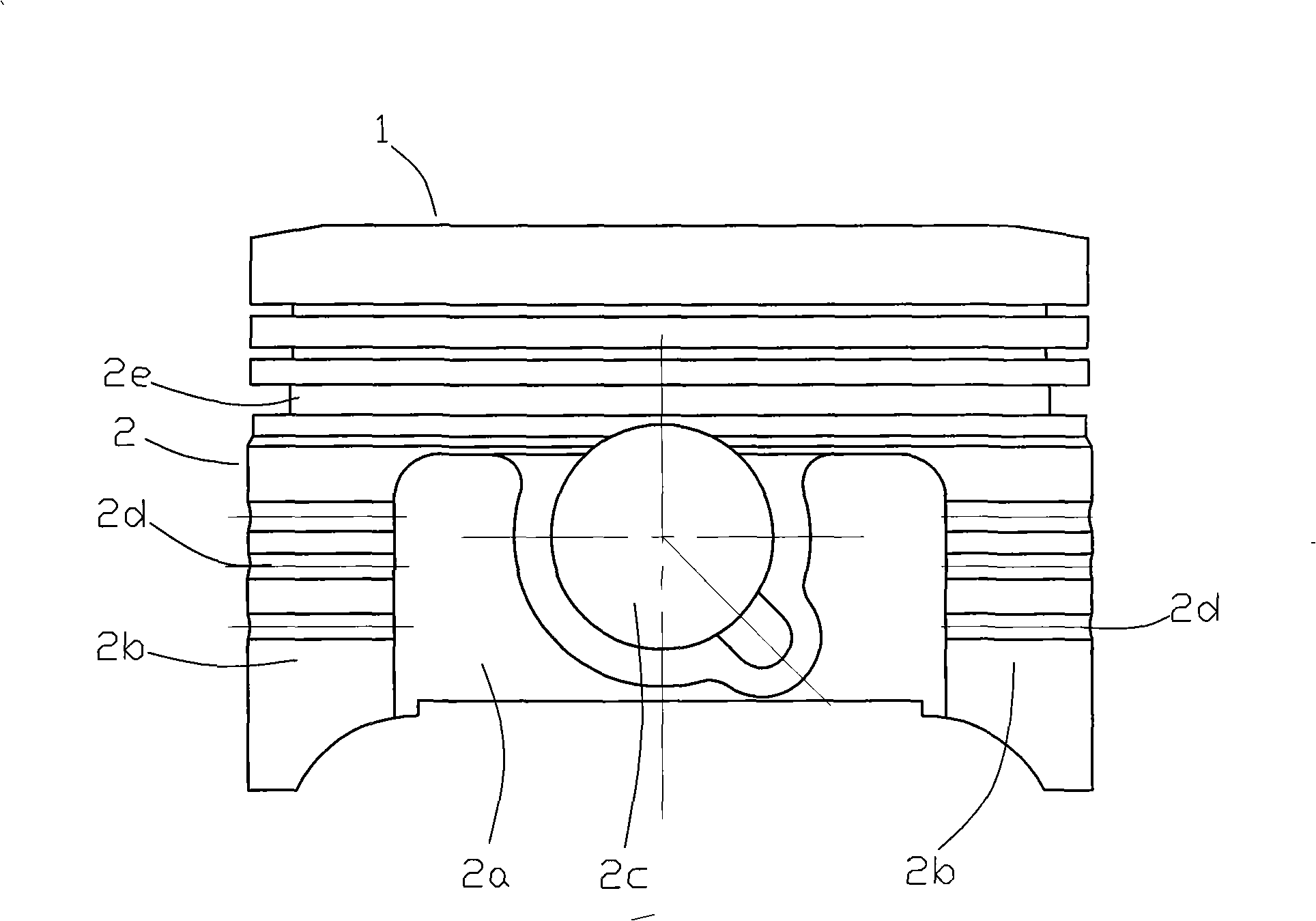

[0013] Such as figure 1 As shown, the present invention is integrally formed by casting, and has a piston head 1 and a piston skirt 2, wherein the top surface of the piston head 1 is a plane, so that the piston can be better pushed to move when the mixed gas is burned. 2. A piston ring installation groove 2e is opened on the circumferential surface of the upper part for installing the piston ring. The peripheral surface of the lower part of the piston skirt 2 is composed of two planes 2a and two arcuate surfaces 2b arranged at intervals, and a piston pin hole 2c is symmetrically opened on the two planes 2a of the lower part of the piston skirt 2 for the piston pin to pass through. , install the piston to the connecting rod. On the two arc surfaces 2b at the bottom of the piston skirt 2, there are 1 to 4 oil grooves 2d which can store oil, and the oil groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com