Detection and package equipment of IC chip

A technology of integrated circuits and packaging equipment, which is applied in the field of testing and packaging equipment, can solve the problems of not being able to meet the actual needs of production flow operations, not being able to meet multiple types/specifications of chips at the same time, and low production efficiency, so as to achieve a fast and efficient testing process. Avoid backlog/disjoint, reduce labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

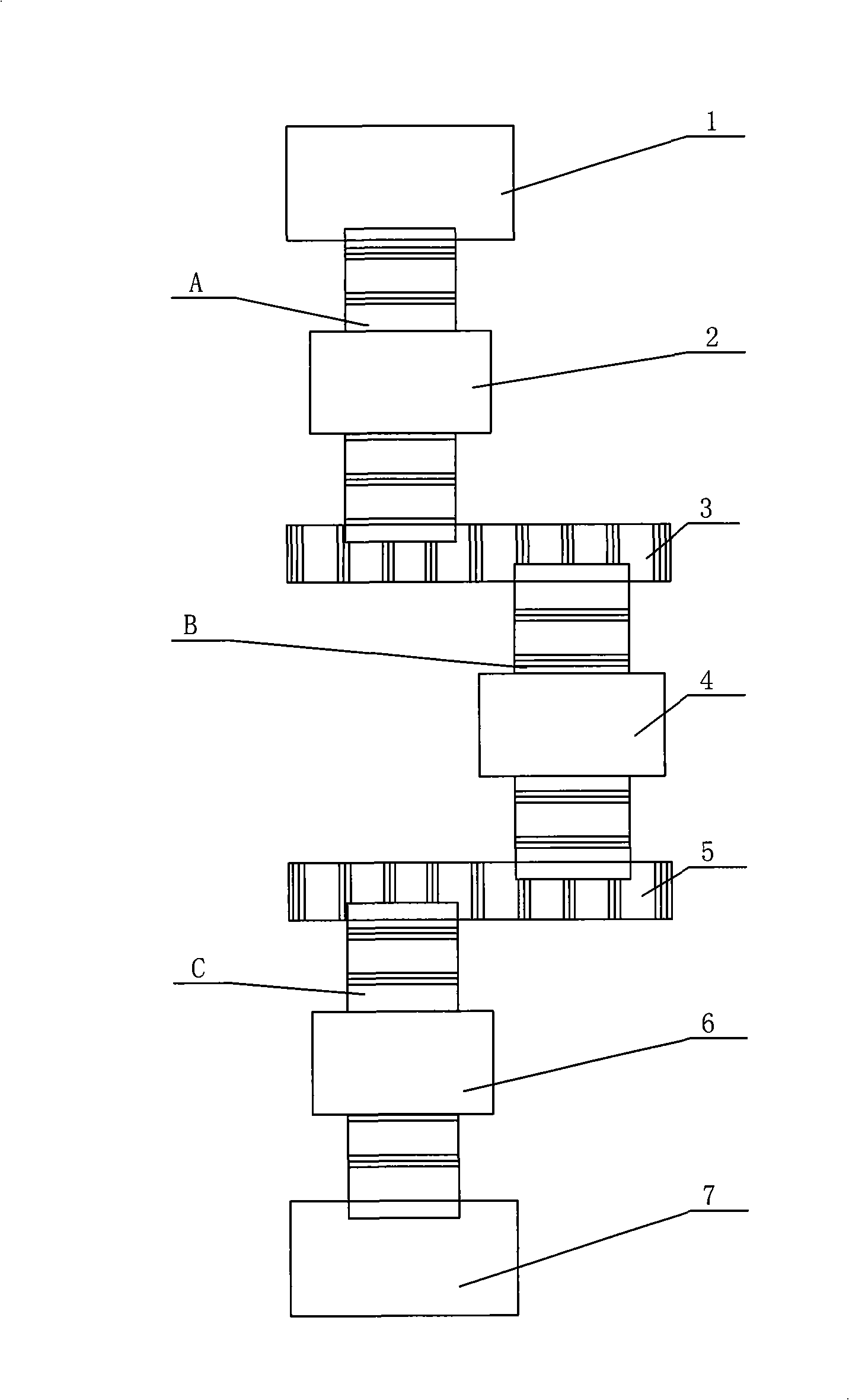

[0018] In Fig. 1, the present invention includes a loading unit, a mark detection unit, a pin detection unit, an exchange area unit, an unqualified area unit, a pick-and-place unit for chips, and a braiding and rolling unit, which is provided with a device to ensure the connection of the above-mentioned units. The main track and the conveyor belt run through the above-mentioned units into a complete process device.

[0019] The main track is composed of three different conveyor belts, which are called No. 1 conveyor belt, No. 2 conveyor belt, and No. 3 conveyor belt; the No. 1 conveyor belt and No. 3 conveyor belt are in a straight line, and the No. Two parallel; three conveyor belts are provided with a supporting plate, used to support the transported pallets, respectively driven by their respective stepping motors and synchronous pulleys with double s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com