Microbiological fuel cell pile

A fuel cell stack and fuel cell technology, applied in the field of environment and new energy, can solve the problems of high cost, unfavorable expansion and amplification, etc., and achieve the effects of small footprint, high output power density, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

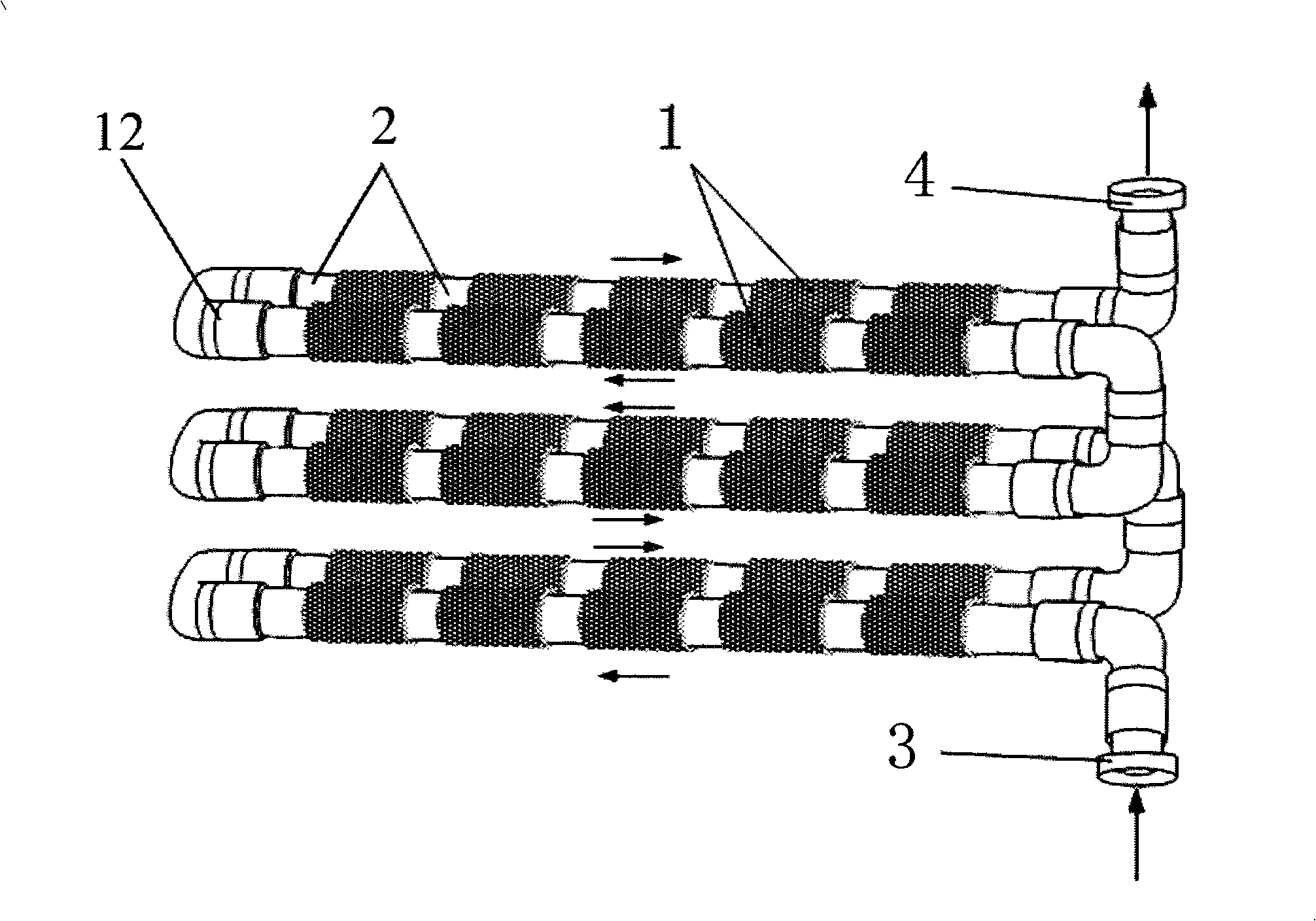

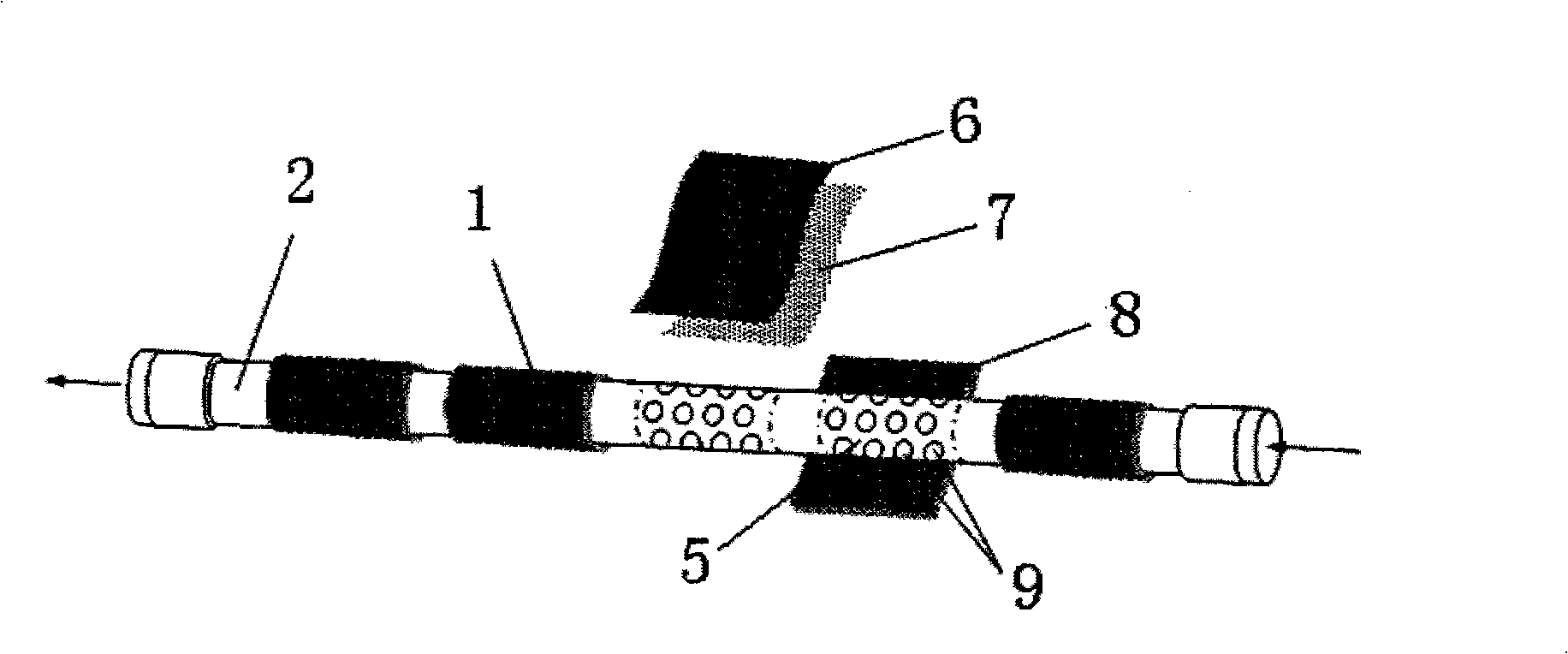

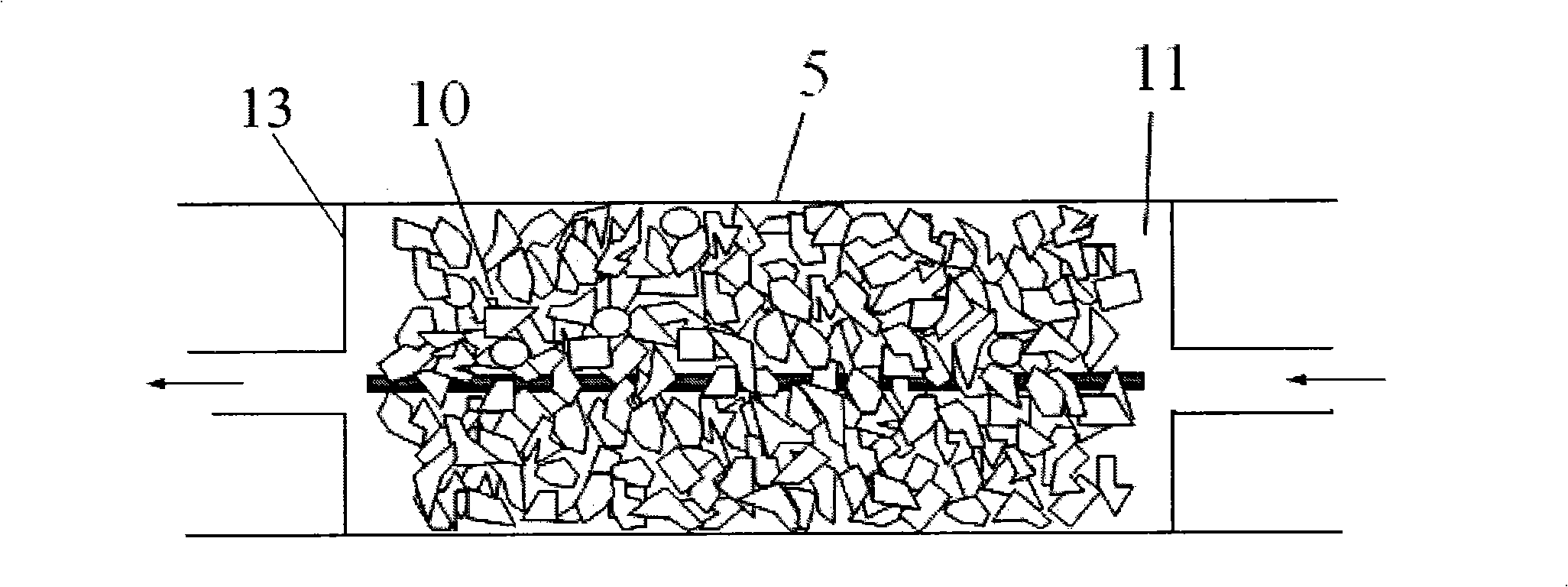

[0030] The invention provides a microbial fuel cell stack, which is a coil structure, as attached figure 1 , attached figure 2 And attached image 3 As shown, the microbial fuel cell stack is composed of several microbial fuel cell cells 1, the microbial fuel cell cells 1 include a hollow skeleton 5, a membrane cathode 8 and an anode 10, and the membrane cathode 8 wraps the hollow skeleton 5 An anode chamber 11 is formed, and the anode 10 is placed in the anode chamber 11; the cathode and the anode are respectively drawn out by wires; the plurality of microbial fuel cell cells 1 are connected end to end through the pipeline 2, and each anode chamber is connected to each other; the pipeline 2 A feed port 3 and a discharge port 4 are provided.

[0031] The skeleton 5 can be integrated with the pipe, that is, a section of hollow is sequentially taken as the skeleton on the pipe, and the distance between the skeletons can be 2-20 cm. The pipes are processed from cheap insulati...

Embodiment 2

[0037] This example illustrates the microbial fuel cell stack provided by the present invention and the method for treating brewery wastewater using the device.

[0038] (1) Construction of battery stack

[0039] as attached figure 1 Shown, be that the PVC pipe interval of pipe diameter 5cm gets section as skeleton 5, and skeleton 5 is long 13cm. Each PVC pipe is arranged with five single microbial fuel cells 1, and the anode chambers of the five single microbial fuel cells 1 are connected and connected end to end in turn through the connection of the pipes. The two PVC pipes are placed side by side to form a layer, and the attached figure 1 As shown in , the six PVC pipes are arranged in three layers, and the six PVC pipes are connected in turn through the elbow 12, and one end of the first and sixth pipes is respectively set as the feed port 3 and the discharge port 4 . In this way, a cell stack is composed of three layers of 30 individual microbial fuel cells, and each i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com