Thermal shrinkage tube dry-expanding machine and dry-expanding machine set

A technology of dry expansion unit and heat shrinkable tube, applied in the field of dry expansion unit, can solve problems such as damage to the physical and mental health of operators, small curvature radius of conveying rollers, and influence on the axial shrinkage rate of products, so as to protect physical and mental health and prevent environmental pollution. and equipment, the effect of keeping internal ventilation unobstructed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

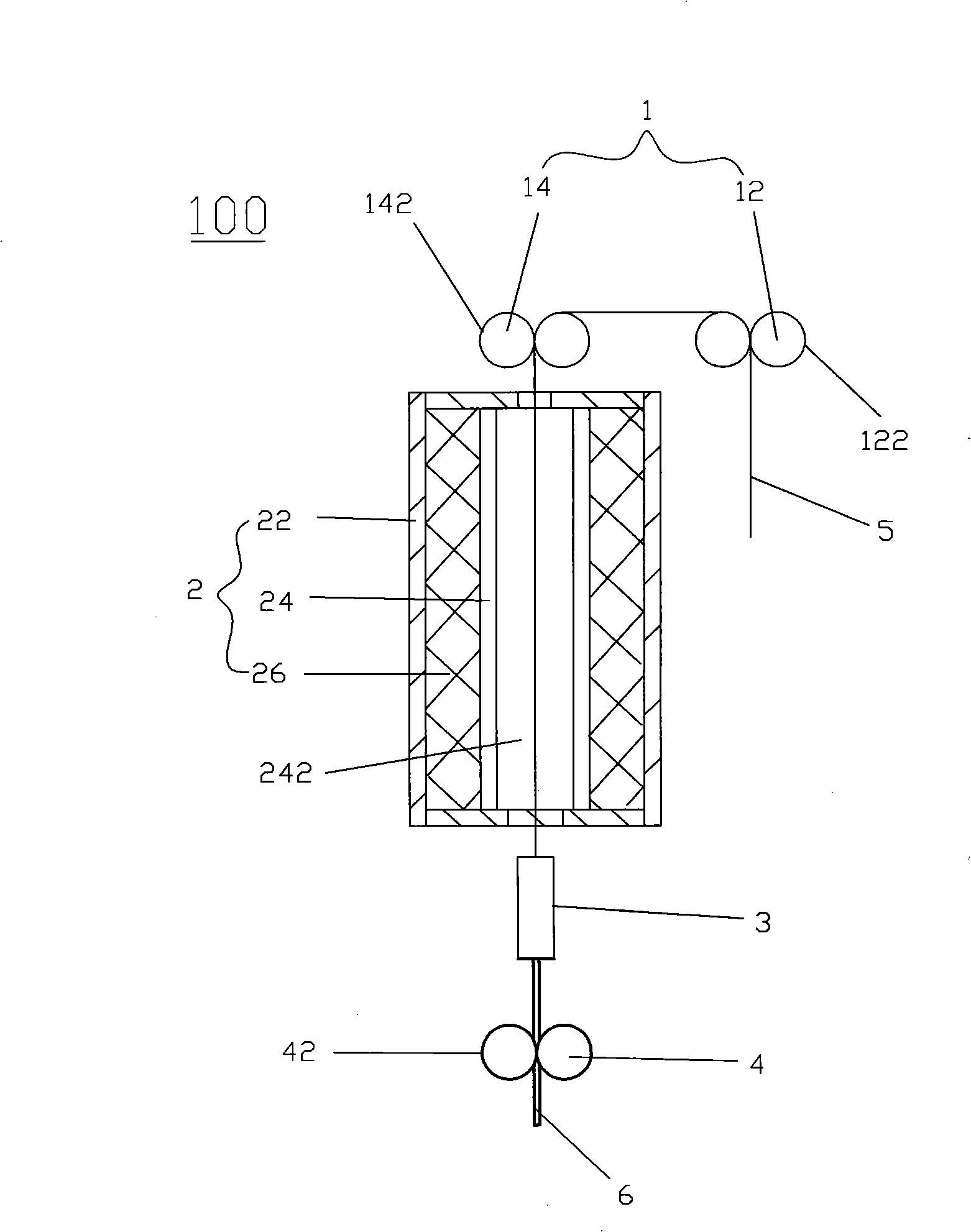

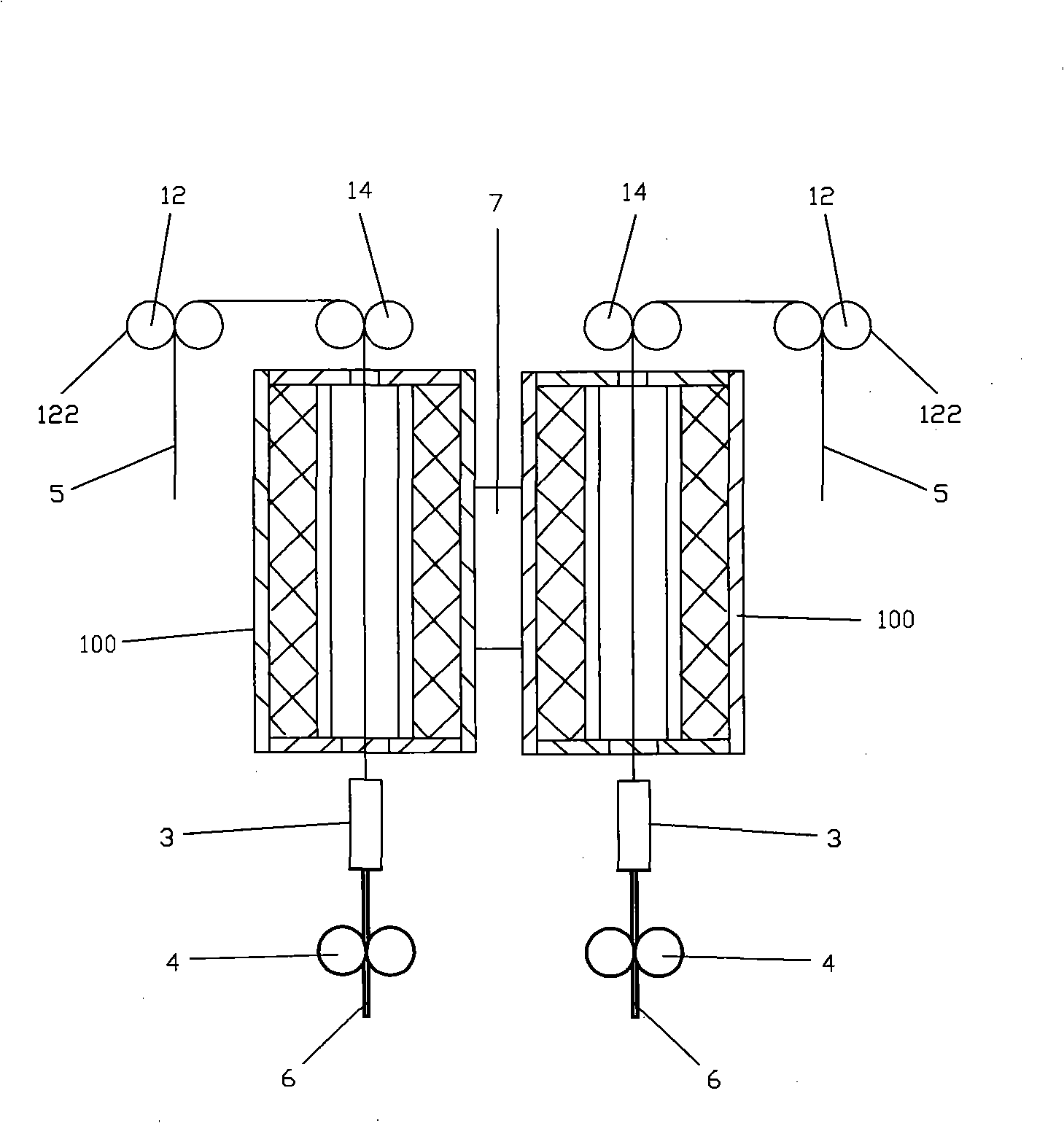

[0022] see figure 1 , a heat shrink tube dry expansion machine 100, which includes a conveying device 1, a heating device 2, an expansion mold 3, and a traction mechanism 4 arranged from top to bottom.

[0023] The conveying device 1 includes a front conveying device 12 and a main conveying device 14 .

[0024] The front conveying device 12 includes two front conveying rollers 122 arranged in parallel at the same height. There may or may not be a gap between the two front conveying rollers 122 .

[0025] The main conveying device 14 is located on one side of the front conveying device 12, and has the same or different height as the front conveying device. The main conveying device 14 includes two main conveying rollers 142 arranged in parallel at the same height. There may or may not be a gap between the two main conveying rollers 142 . The axial directions of the two front conveying rollers 122 and the axial directions of the two main conveying rollers 142 are parallel to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com