Polyester imine aluminium wire wire coating enamel modifier

A polyesterimide aluminum, enameled wire paint technology, applied in the direction of coating, can solve the problems of the use and promotion of enameled aluminum wire, the failure to meet the thermal level requirements, the decline of thermal shock performance, etc., to eliminate the influence of thermal stress , reduce production costs, improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

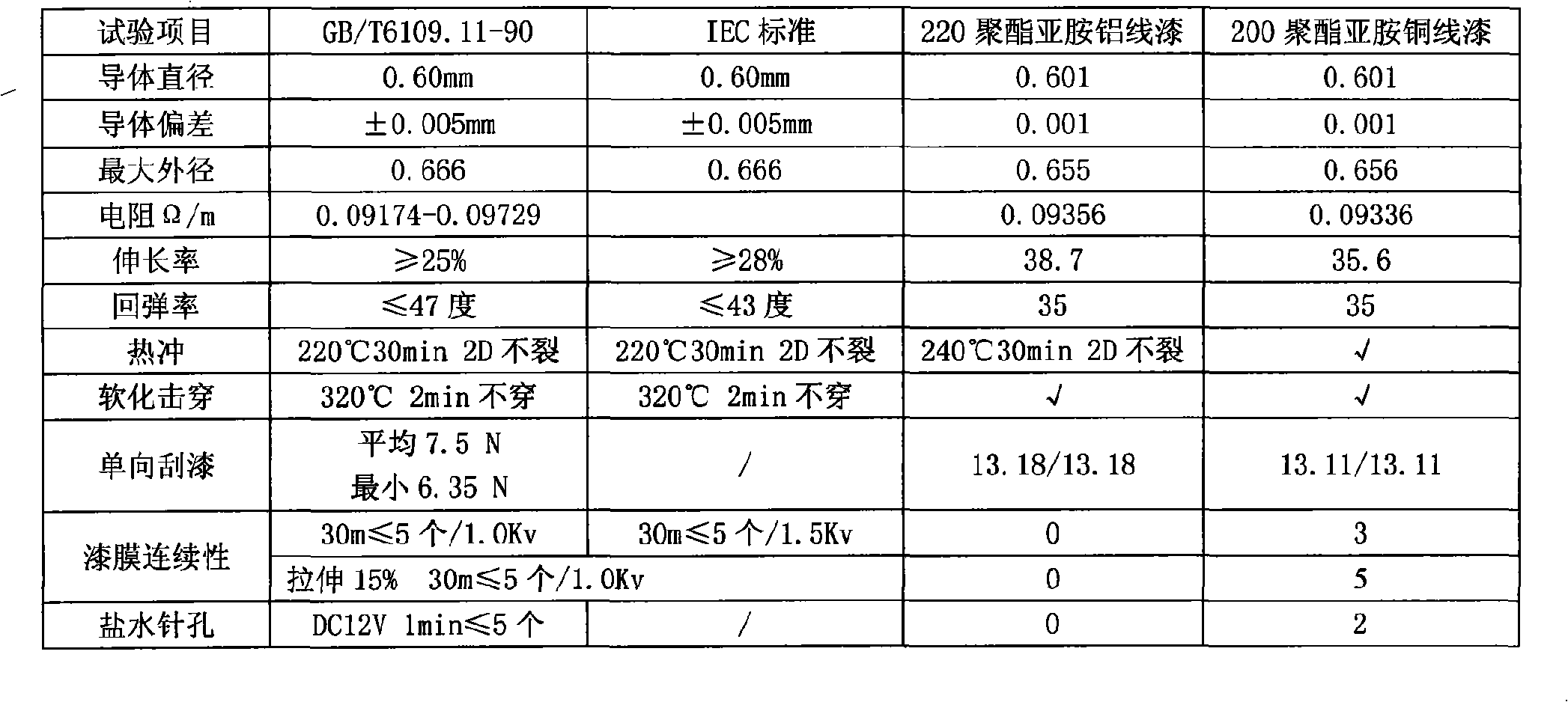

Image

Examples

Embodiment Construction

[0023] A polyesterimide aluminum wire enameled wire varnish modifier, comprising the following components in parts by weight:

[0024] Example 1

Example 2

Example 3

Example 4

Example 5

Phenolic Resin

10

15

20

25

30

epoxy resin

10

12

15

18

20

polyhydroxy acrylic resin

1

3

5

8

10

Fluorocarbon Surfactant

1

2

3

4

5

m-p-cresol

30

35

40

50

60

[0025] The preparation method is: mix phenolic resin, epoxy resin, polyhydroxy acrylic resin adhesive and fluorocarbon surfactant according to the formula and dissolve them in m-p-cresol, stir evenly at 40-60°C to make a stable transparent liquid Oil.

[0026] Adding the above-mentioned modifier during the production process of polyesterimide wire enamel, the prepared polyesterimide wire enamel has excellent adhesion, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com