Method for preparing ethyl alcohol with potatoes

A technology for ethanol and potatoes, which is applied in the field of ethanol preparation, can solve the problems of reduction and waste of starch in ethanol yield, etc., and achieve the effects of saving water resources, less starch inclusions, and high separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Pretreatment: remove the sundries and moldy parts in the dried cassava, crush them, and pass through a 1.5mm sieve to obtain cassava flour;

[0028] Mixing material: In the mixing tank, mix cassava flour and 60°C hot water according to 1:3.158, and add a-amylase at the same time, the ratio is 1g of cassava flour and 17 μg of a-amylase, stir evenly, and enter the liquefaction tank;

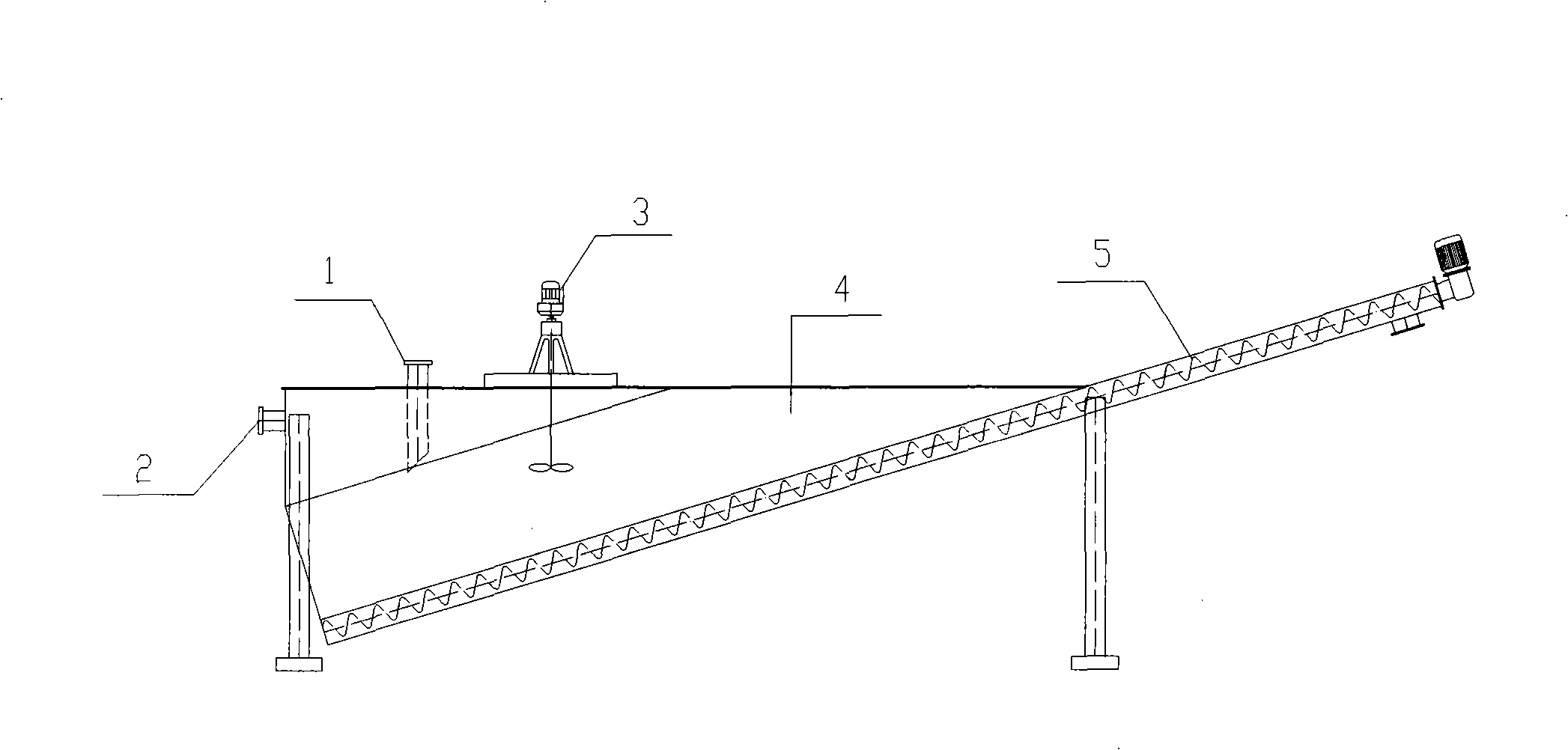

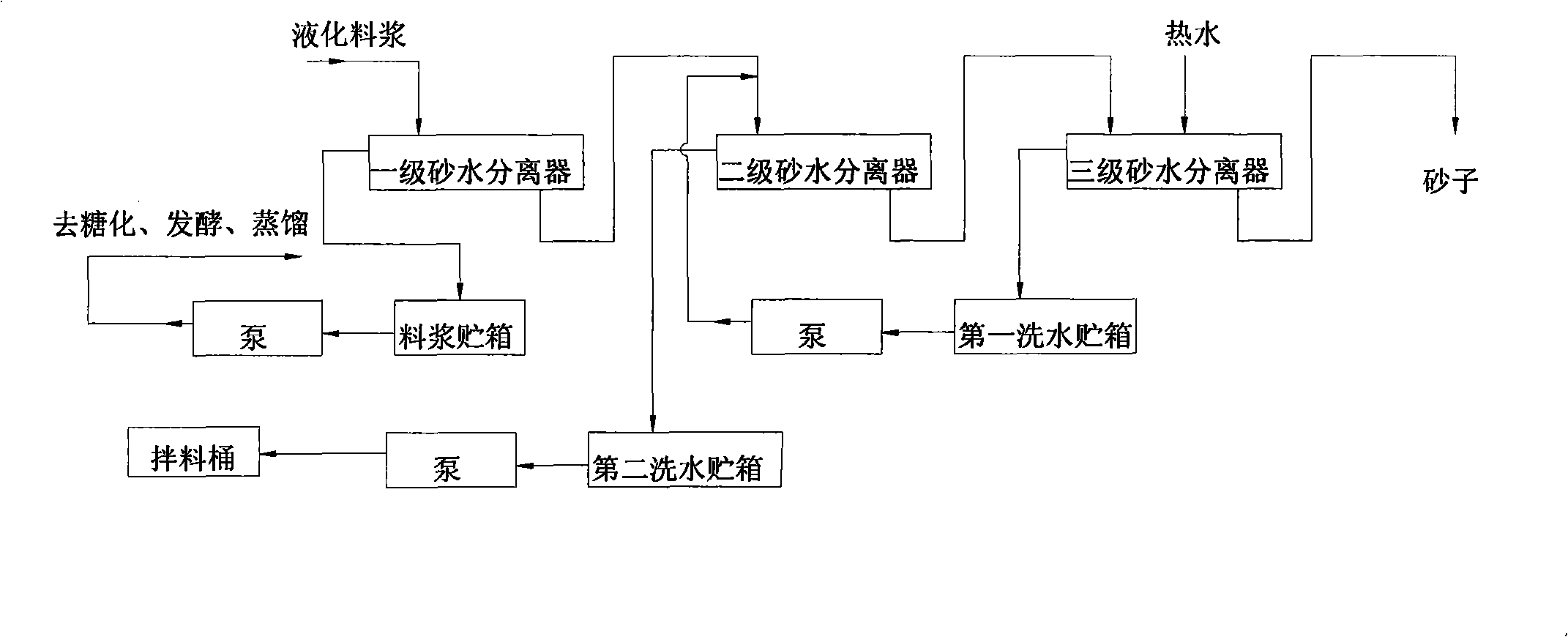

[0029] Liquefaction: heat up to 90°C under stirring, then add a-amylase at a ratio of 1g tapioca flour to 33μg a-amylase, continue stirring, and liquefy for 50 minutes to obtain a liquefied slurry, which enters the sand-water separator;

[0030] Sand removal: keep the liquefied slurry at 85°C, stir and settle at a stirring speed of 30r / min, then separate the sand, and wash the sand twice with 90°C hot water. The overflowed supernatant is saccharified, fermented and distilled to obtain ethanol.

[0031] Finally, the sand was weighed dry, and the sand removal efficiency was calculated to be 9...

Embodiment 2

[0033] Pretreatment: remove the sundries and moldy parts in the dried potatoes, crush them, and pass through a 1.5mm sieve to obtain cassava flour;

[0034] Mixing material: mix potato flour and 65°C hot water according to a certain material ratio (the material ratio is 1:2.809), and add a-amylase at the same time, the ratio is 1g potato flour and 17 μg a-amylase, stir evenly, into the liquefaction tank;

[0035] Liquefaction: heat up to 105°C under stirring, then add a-amylase, the ratio is 1g cassava flour, add 40μg a-amylase μg / g cassava flour, continue stirring, liquefy for 1 hour, get liquefied slurry, enter sand-water separation device;

[0036] Sand removal: keep the liquefied slurry at 95°C, use three-stage sand removal, stir and settle at a stirring speed of 40r / min, then separate the sand, and wash the sand twice with 90°C hot water. The overflowed supernatant is saccharified, fermented and distilled to obtain ethanol.

[0037] Finally, the sand was weighed dry, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com