Novel non-leakage synchronous expansion steam lance

A soot blower and long telescopic technology, applied in the field of soot blowers and new leak-free synchronous long telescopic steam soot blowers, can solve the problems of low reliability of dynamic sealing friction pair, long sealing length, easy occurrence of air leakage, etc. Achieve the effect of high soot blowing efficiency, high reliability and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

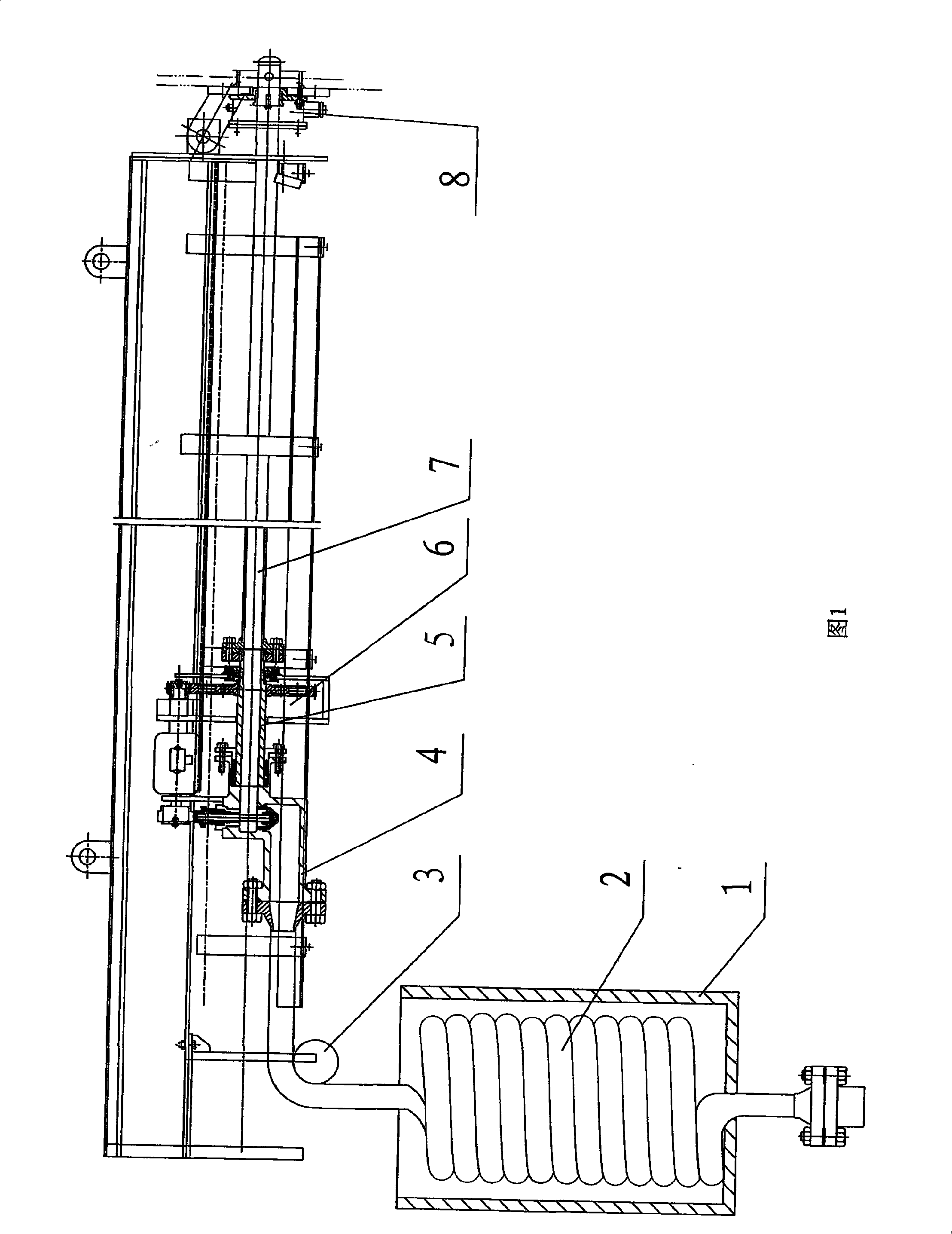

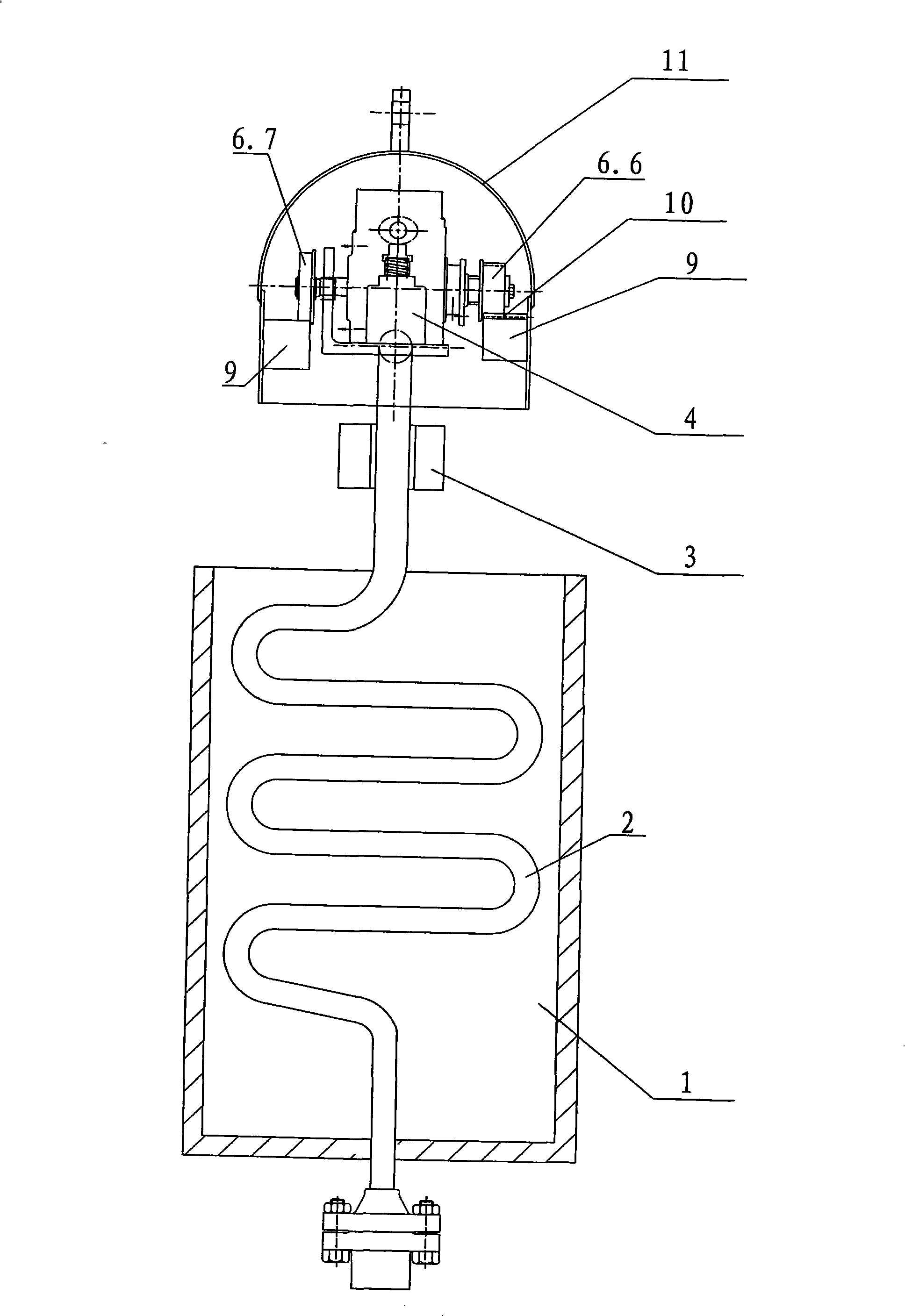

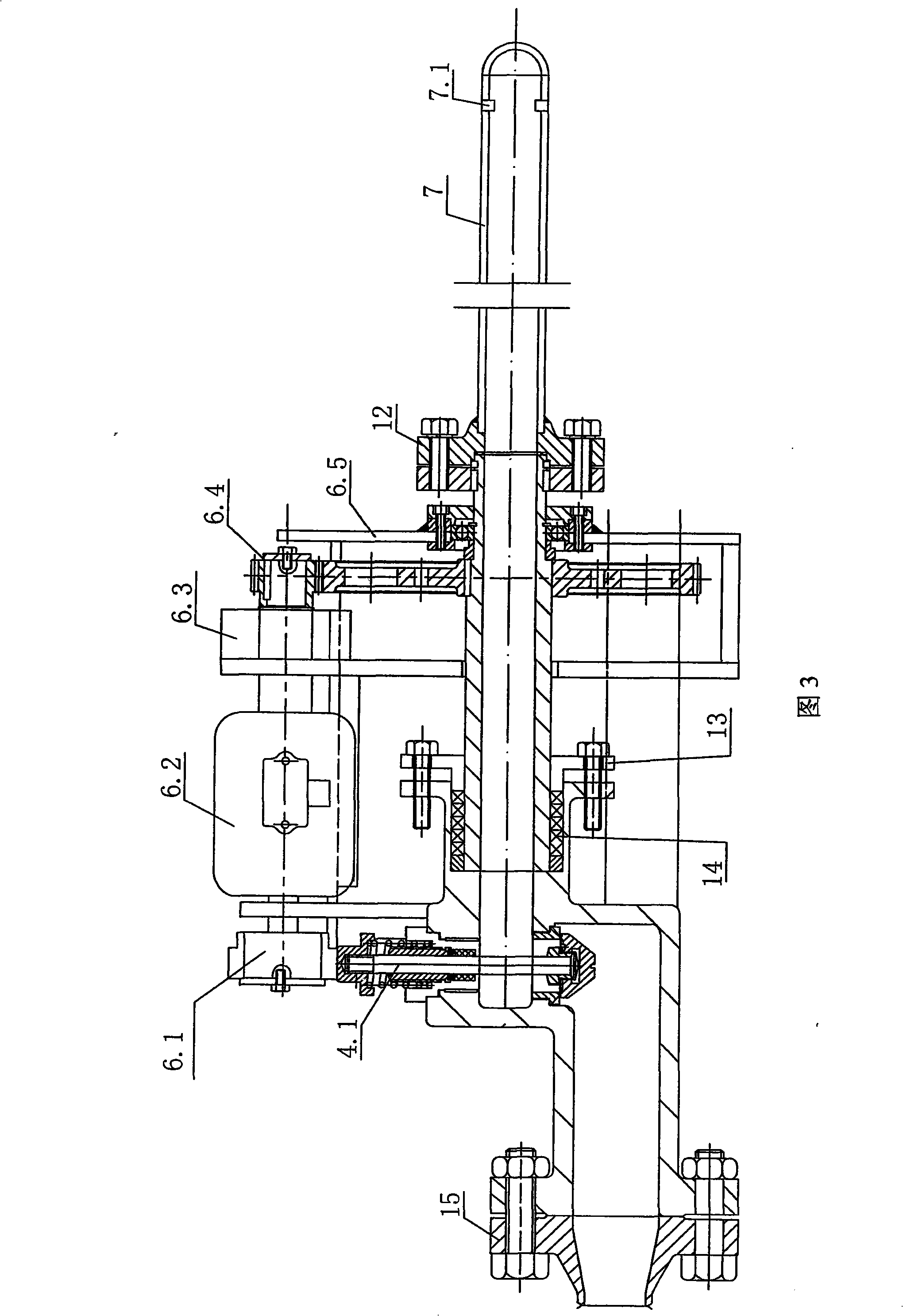

[0024] Referring to Figures 1-2, the novel non-leakage synchronous long telescopic steam soot blower of the present invention mainly consists of a housing 11, a support guide rail 9, a guide and drive rack 10, a synchronous drive device 6, a connecting pipe 5, and a soot blowing pipe 7 , steam conduction valve 4, guide wheel 3, hose 2 and hose collection pipe 1. There are two support rails 9 (or one), one on the left and one on the left, respectively connected to the left inner side and the right inner side of the housing 11, the guide and drive rack 10 is arranged on one of the supporting rails, and the synchronous drive The device 6 is supported on the left and right supporting guide rails 9 .

[0025] The pipe wall of the soot blowing pipe 7 is provided with a cyclone 7.1, one end of the soot blowing pipe 7 is fixedly connected with the furnace wall connection sealing mechanism 8, and the other end is connected with one end of the connecting pipe 5 through the connecting fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com