Asymmetric structure three-dimensional co-vibrating spherical vector hydrophone

A vector hydrophone, an asymmetric technology, is applied to transducers used underwater, vibration measurement in fluids, instruments, etc. The hydrophone has high density, inconsistent sensitivity and phase characteristics, etc., to ensure that the acoustic characteristics do not change, reduce the number of internal sensors, and reduce the overall average density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

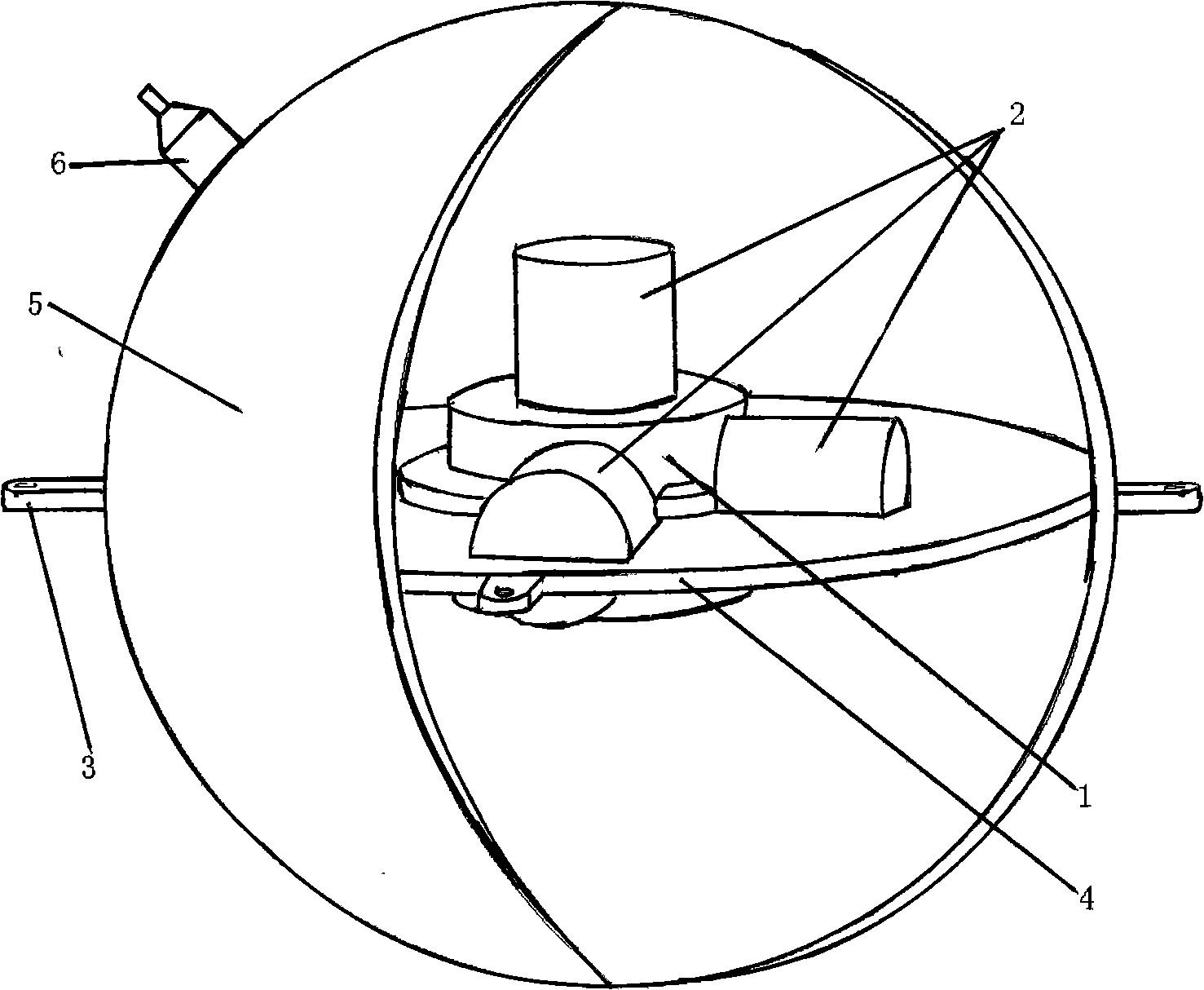

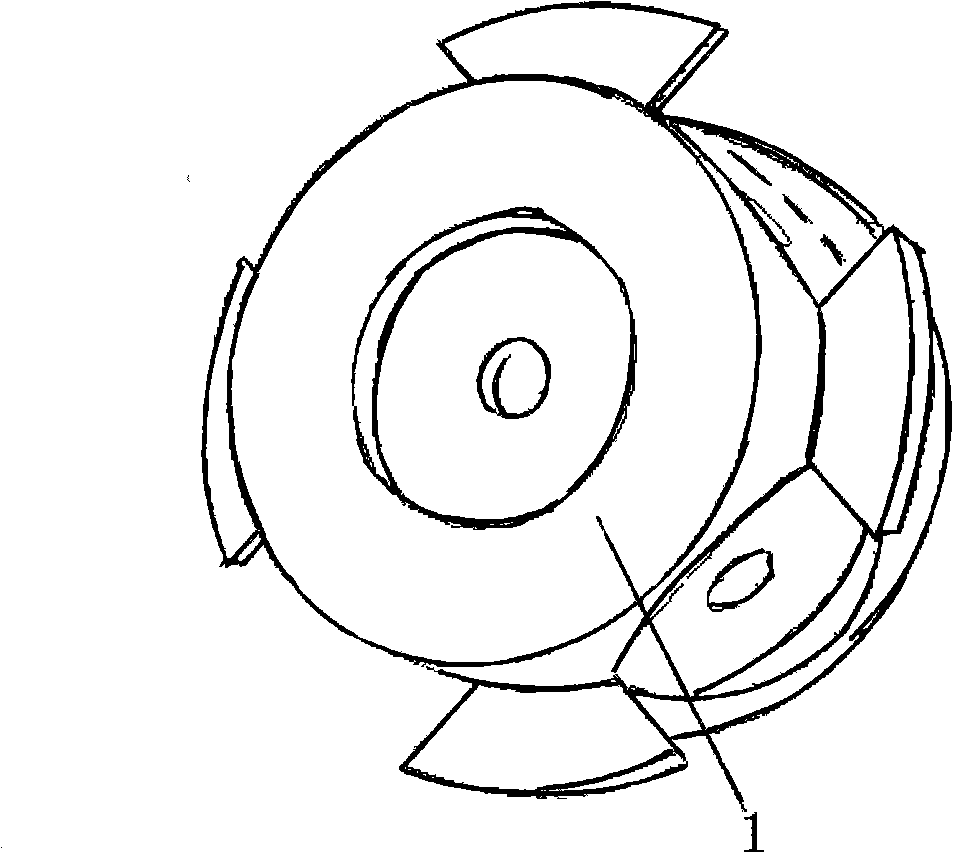

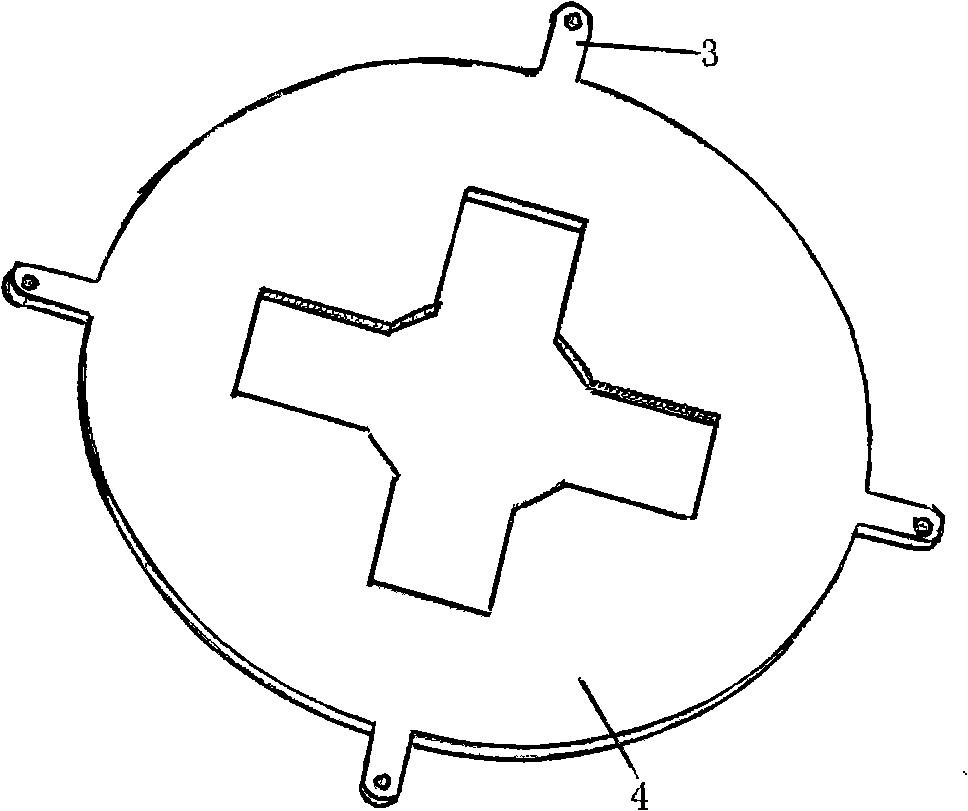

[0021] combine Figure 1 to Figure 3 , the asymmetric structure three-dimensional co-vibration spherical vector hydrophone of the present invention consists of a core vibrator composed of three piezoelectric accelerometers 2 installed on the center mass 1 and a support flange 4 with a suspension ring 3 and an upper and lower Two hemispherical shells 5 and an output cable 6 are formed. The core vibrator is fixed inside the support flange 4 by bolts, and the support flange 4 is sandwiched between the upper and lower hemispherical shells 5 by bolts and sealing rings.

[0022] First, three piezoelectric accelerometers 2 are axially installed on the central mass 1 to form a core vibrator, and then the core vibrator is fixed on the support flange 4 with a suspension ring 3 with bolts, and finally the support method The blue plate 4 is sandwiched between the upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com