Method for establishing micro-electromechanical variable cross-section clamped beam system-level macro model

A technique for establishing method and changing section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

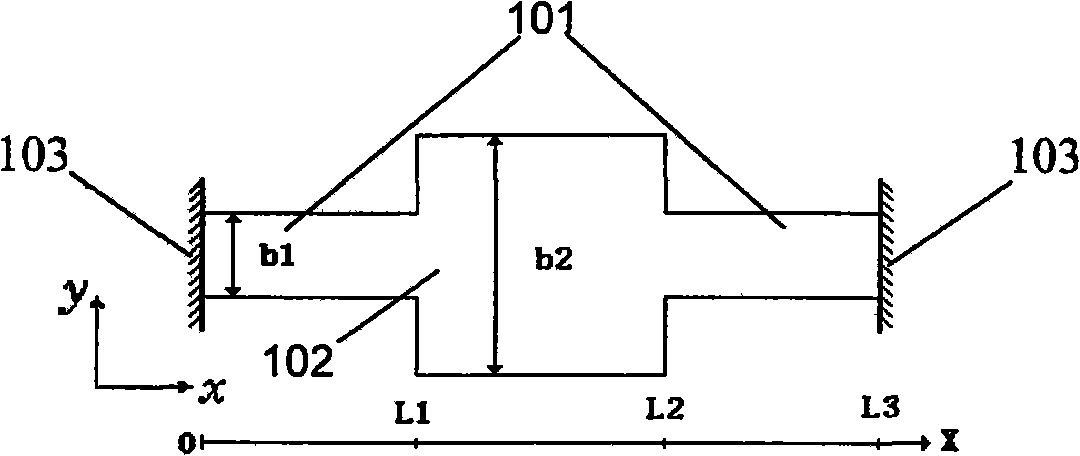

[0019] 1. Structure of fixed-support variable-section beam

[0020] see figure 1 , the double-ended fixed-support variable-section beam is connected to the narrow beam 101 by two fixed support points 103 , one end of the two narrow beams 101 is connected to the fixed-support boundary, and the other side is connected to the wide beam 102 . The lower part of the beam is an air layer, and the thickness of the air layer is usually on the order of microns. When an external force acts on the variable-section beam, the beam will undergo bending deformation, which will cause elastic recovery force due to the deformation. Within the range of elastic deformation, the greater the deformation caused by the external force, the greater the elastic recovery force. . When the magnitude of the elastic restoring force is equal to the magnitude of the external force, the beam reaches equilibrium and remains at rest. When the external force is removed, the beam will return to its original posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com