Double line box girder downward mobile formwork bridge fabrication machine and construction method thereof

A technology of mobile formwork and construction methods, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as long construction period, high safety risk, complicated process, etc., achieve large load bearing, save construction period, and linear control accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

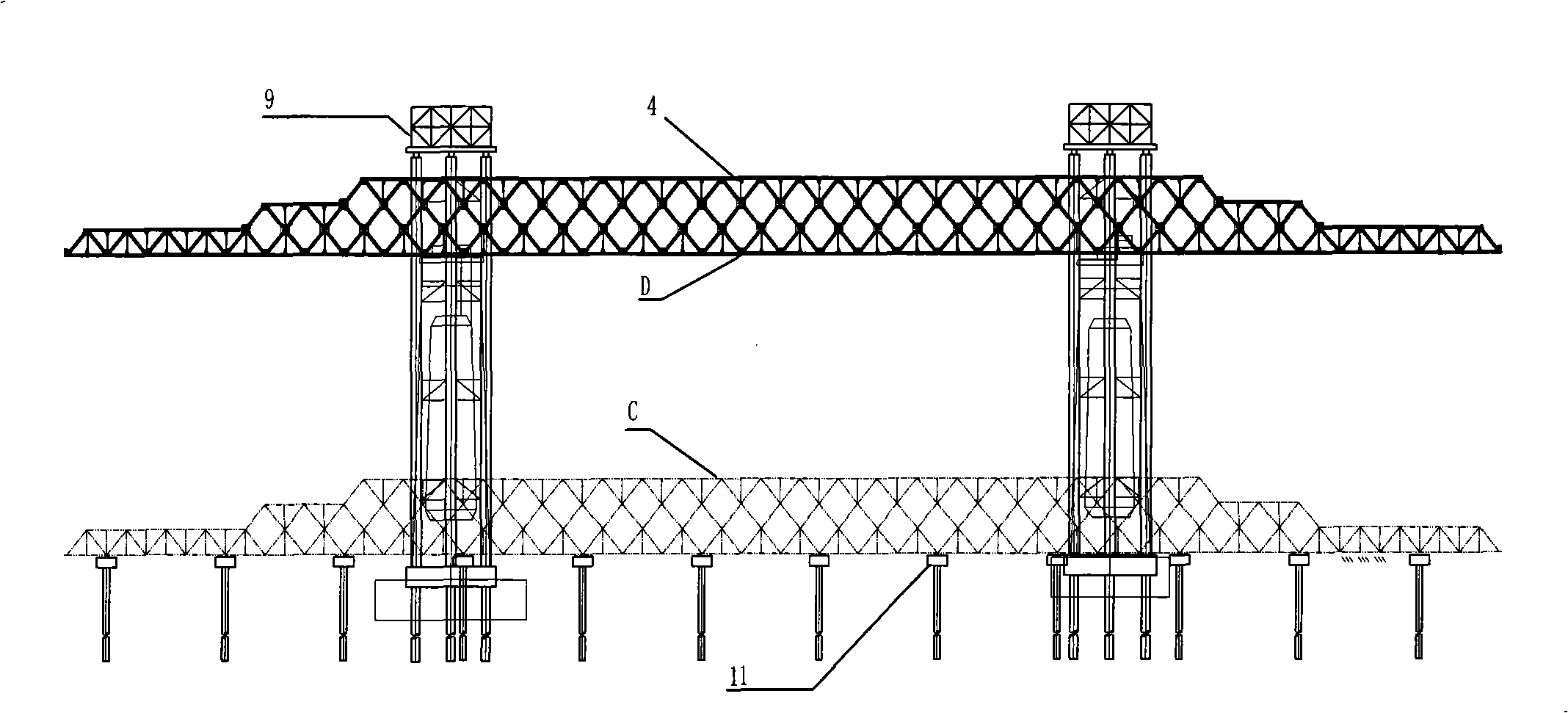

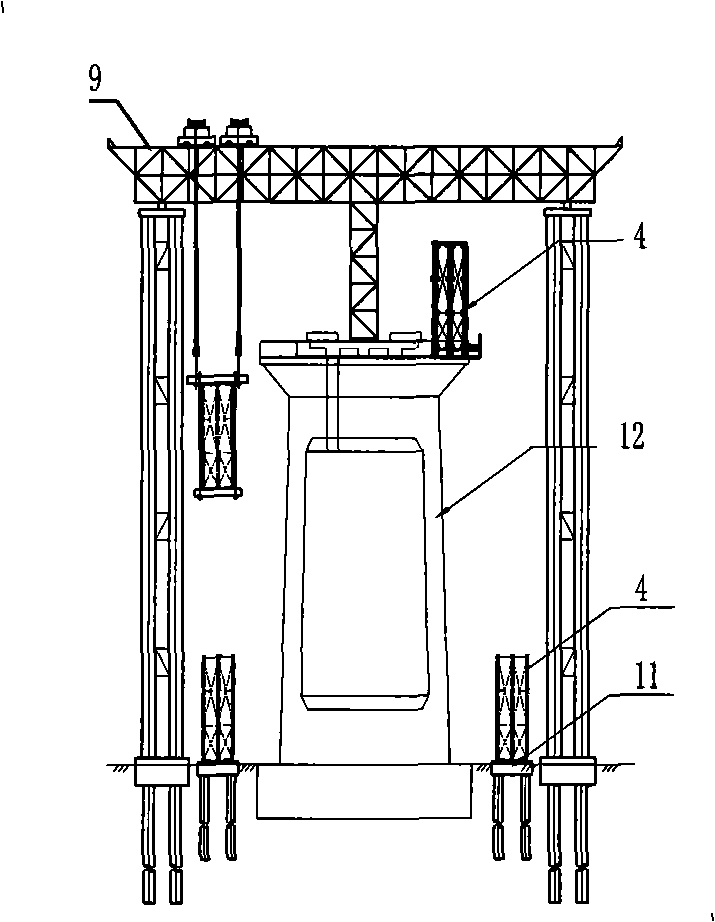

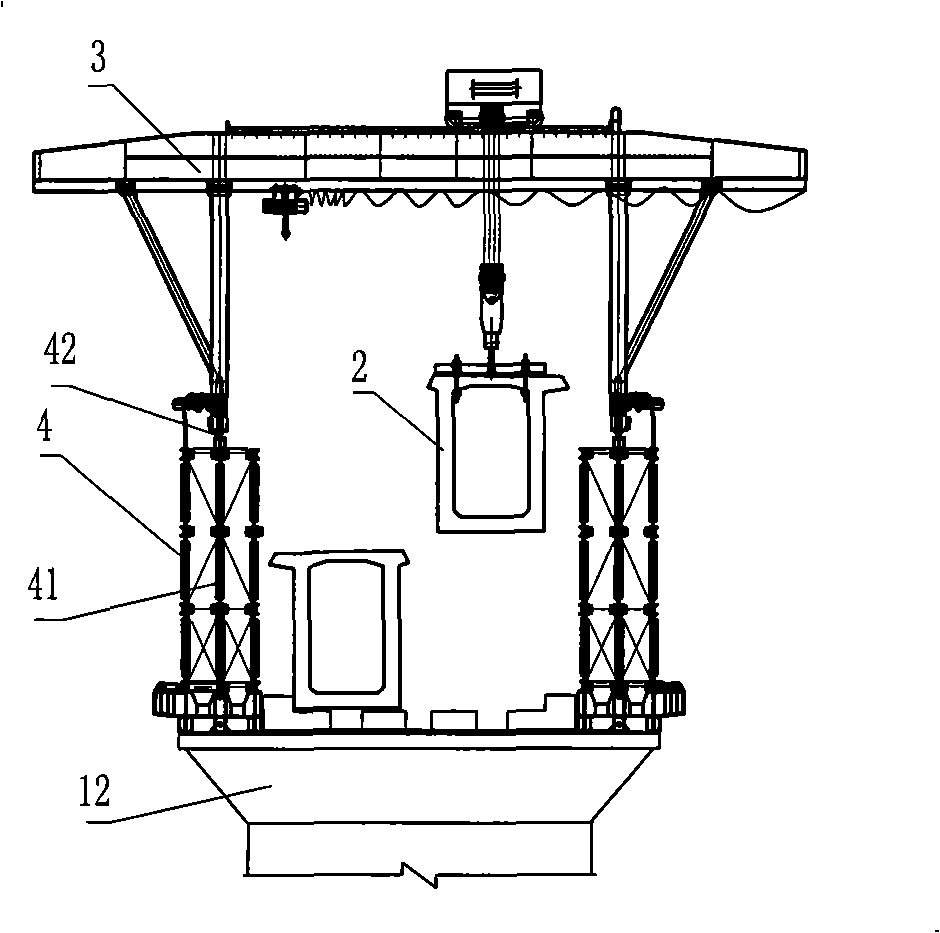

[0027] Bridge building machine structure of the present invention is as Fig. 3, Figure 5 As shown, the main girder of the bridge-building machine adopts two groups of parallel main trusses 4 structures, and the front and rear ends of each set of main trusses 4 are respectively connected with the front guide beam 5 and the rear guide beam 7; the upper side between the two main trusses 4 passes through Multiple cross-links 13 are connected and fixed, and the lower side is connected with multiple lower shoulder beams 6; the two main trusses 4 are supported on two adjacent piers 12 through vertical and horizontal sliding seats 8 of flat plate structure. The bridge building machine is assembled with high-strength disassembled military beams and new rods. The center distance of the two sets of main trusses is 12.8m, the span of the main truss is 64...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com