Building method of floor fissure strata tunnel deformation joint anti-seepage structure and anti-seepage structure

A technology of deformation joints and tunnels, applied in tunnels, tunnel linings, underwater structures, etc., can solve the problems of anti-seepage technology that cannot meet anti-seepage requirements, lose sealing and waterproofing, and reduce sealing and waterproofing effects, so as to promote rheological deformation , to ensure sealing and anti-seepage, and to improve the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

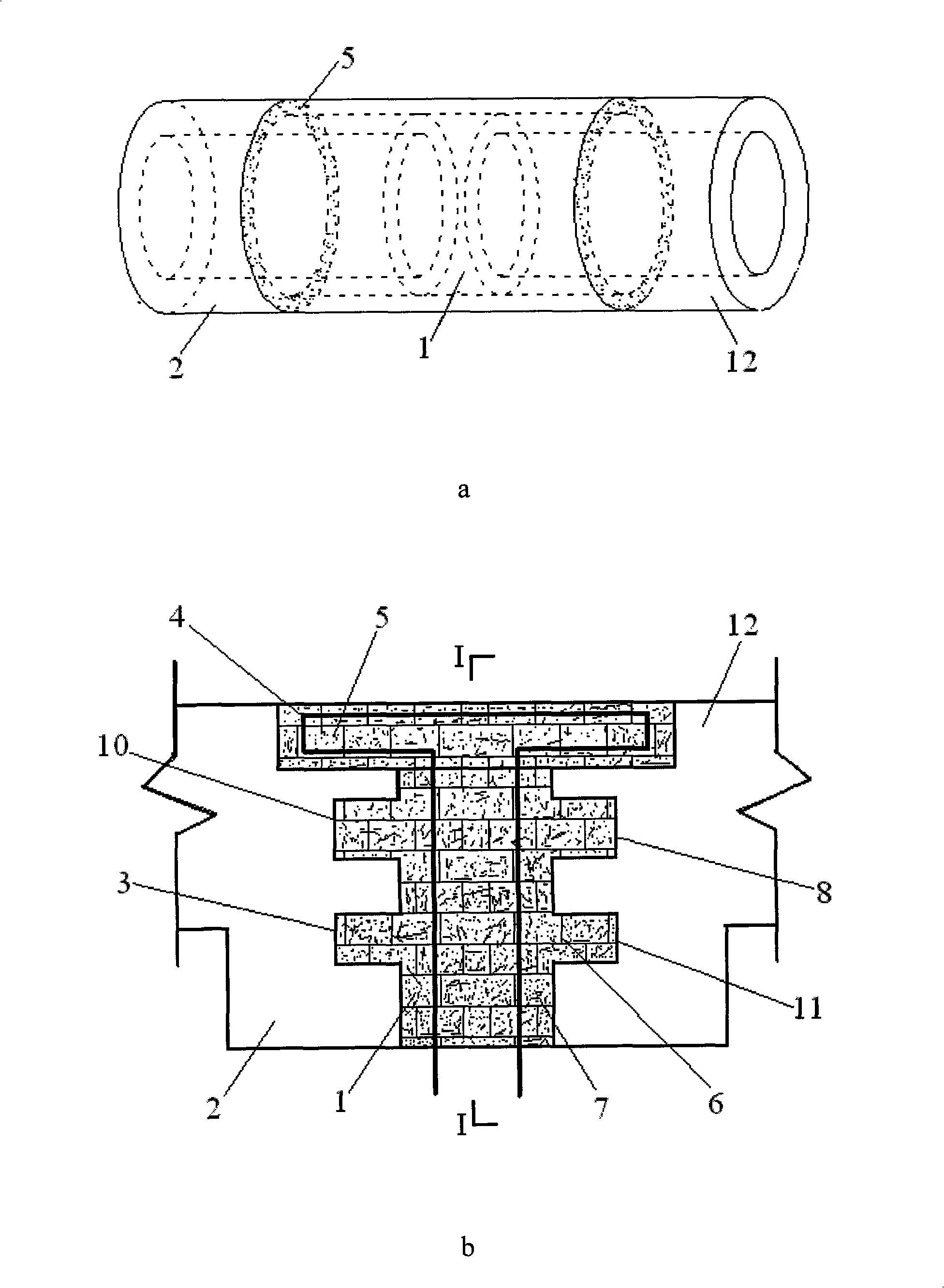

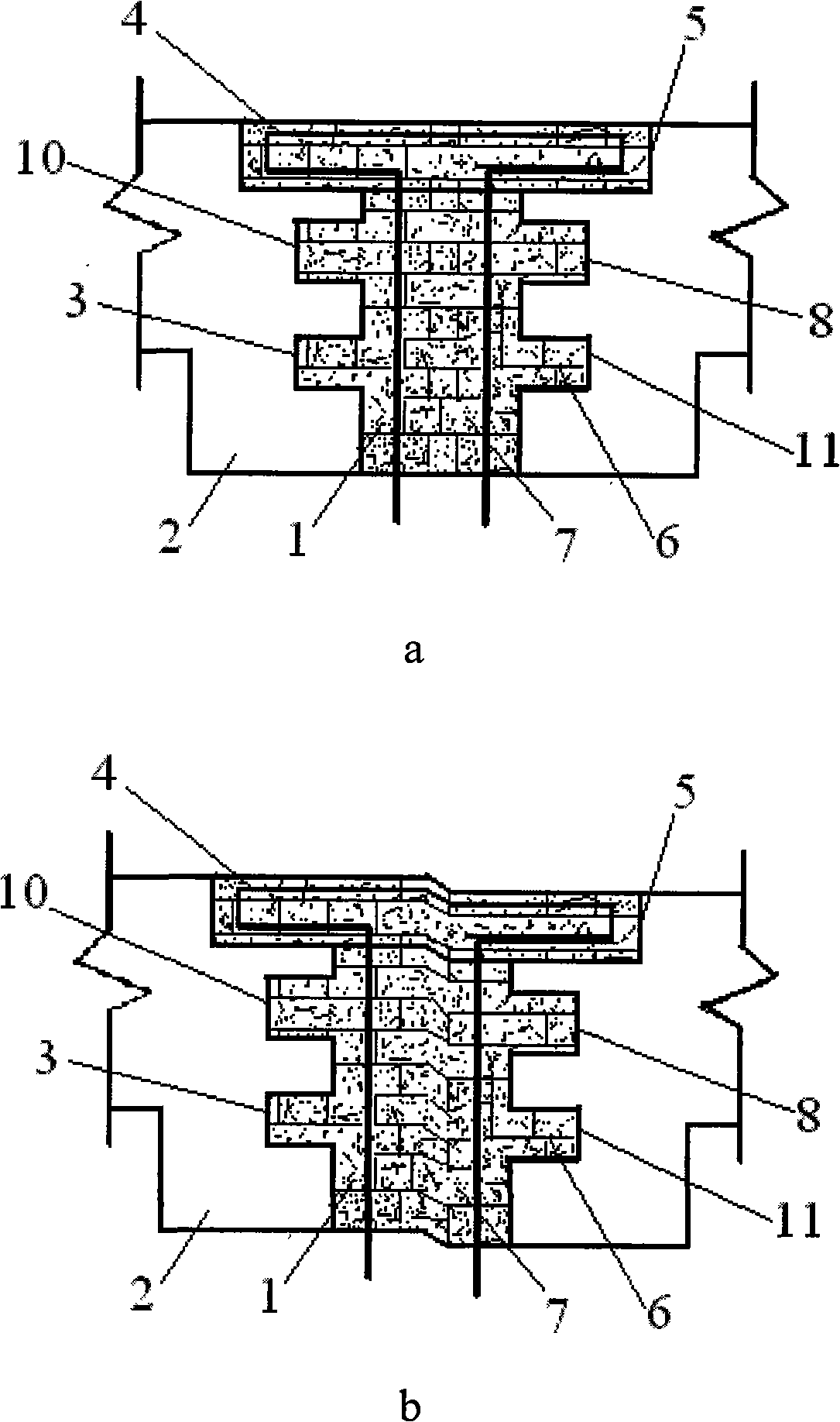

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0039] The construction method of deformation joint anti-seepage structure of the present invention, carries out according to the following steps:

[0040] Step 1: Preparation of reinforced asphalt concrete flexible slab

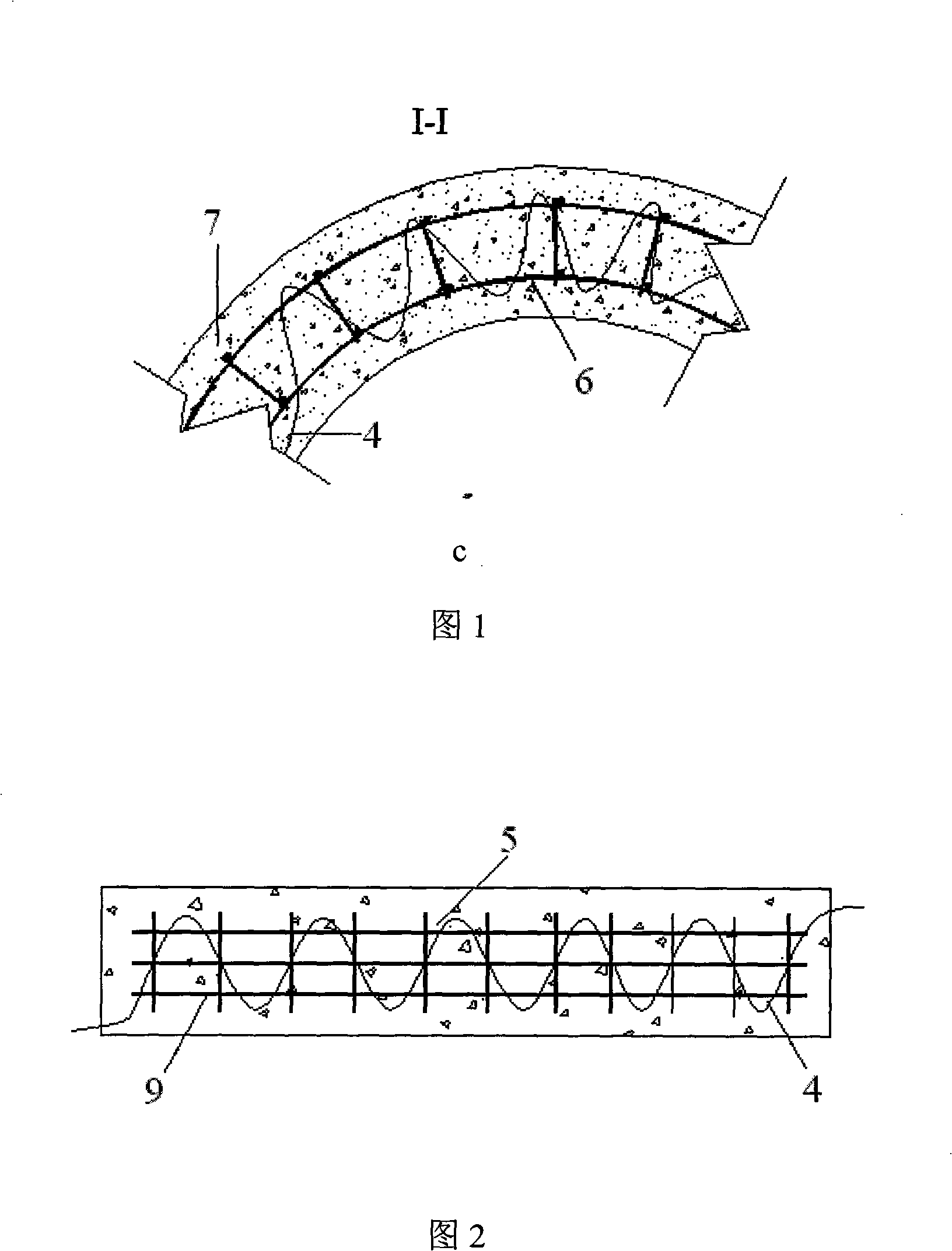

[0041] Take modified asphalt, well-graded gravel, reinforced material 9 and resistance wire 4 respectively, make modified asphalt and well-graded gravel into modified asphalt concrete, and lay the modified asphalt concrete and reinforced material 9 in layers , and lay resistance wires 4 in a "snake" shape, and then use the method of rolling to make a reinforced asphalt concrete flexible board 5 with a thickness of 6-10 cm and a width of 140-180 cm. The two ends of the resistance wire 4 are made of Reinforced asphalt concrete flexible plate 5 protrudes;

[0042] The used reinforcing material 9 is a kind of high molecular p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com