Method and apparatus of fine distribution of white light interference sample surface shapes

A technology of white light interference and surface shape, which is used in measurement devices, optical devices, instruments, etc., and can solve the problems of low measurement accuracy and work stability, long data sampling time, and poor anti-interference ability of instruments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

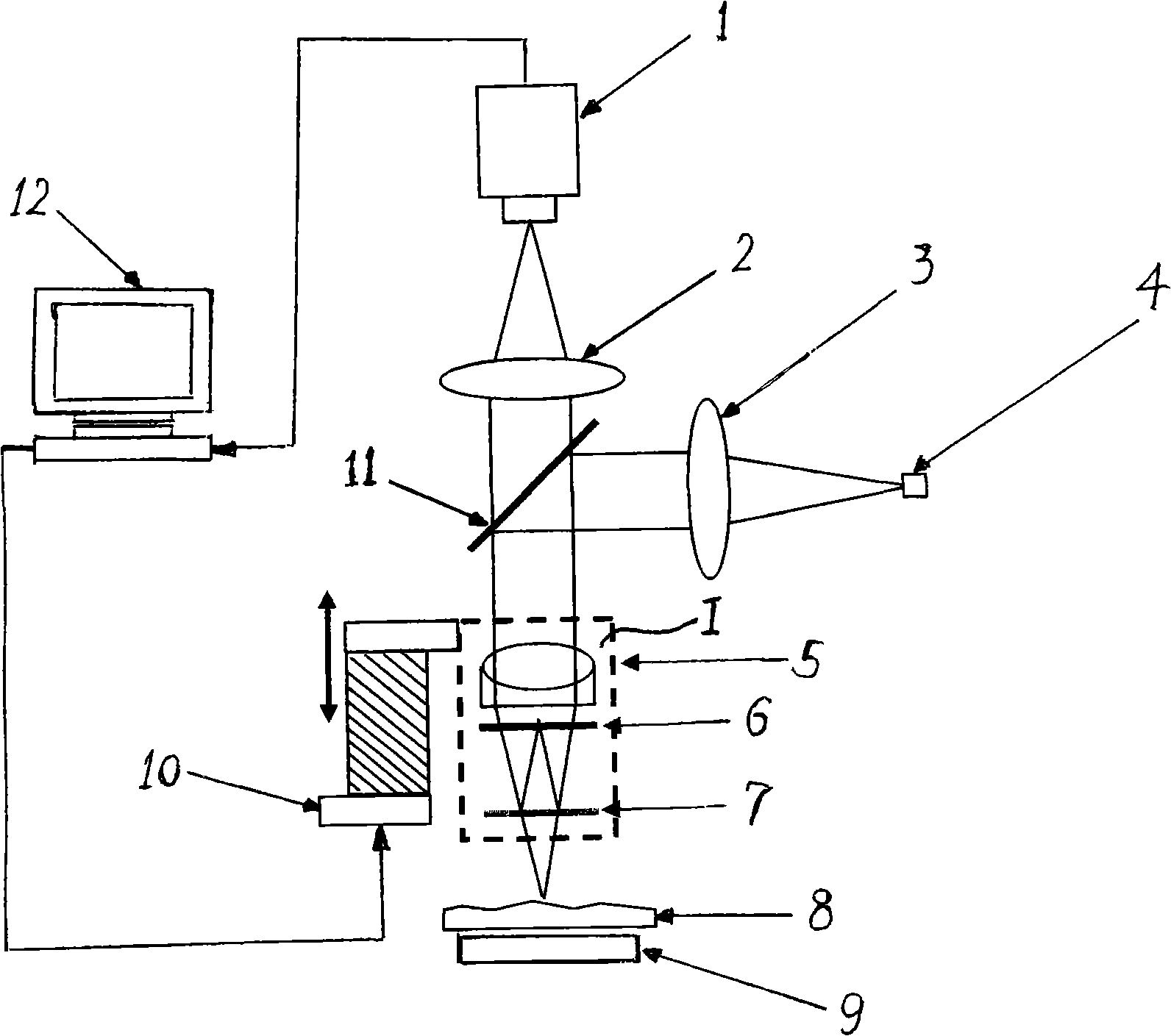

[0011] Referring to the accompanying drawings, the device for white light interferometric measurement of the fine distribution of the sample surface shape of the present invention consists of a white light source 4, a lens 3, a semi-reflective beam splitter 11, a CCD camera 1, a lens 2, an interference microscope objective lens 1, and a sample placement It is composed of a platform 9 and a closed-loop piezoelectric ceramic driver 10, etc. The white light source 4, the lens 3 and the semi-reflective beam splitter 11 constitute the lighting source system of the measuring device, and the illuminating light beam emitted by it is divided into the downlink reflected light and the uplink reflected light after passing through the semi-reflected beam splitter 11 set at an inclination angle of 45°. Two beams of light are transmitted. CCD camera 1 and lens 2 constitute the optical imaging system of the device, and are arranged on the optical axis direction of light transmitted by half-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com