Method for measuring powder body material electric conductivity and electric conductivity measuring apparatus suitable for the method

A measurement method and technology of powder materials, applied in the direction of material impedance, etc., can solve the problems of the influence of compaction density lithium ions, the first discharge efficiency of the material gram capacity and the unfavorable cycle performance, and achieve the effect of optimizing the electrode material formula.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

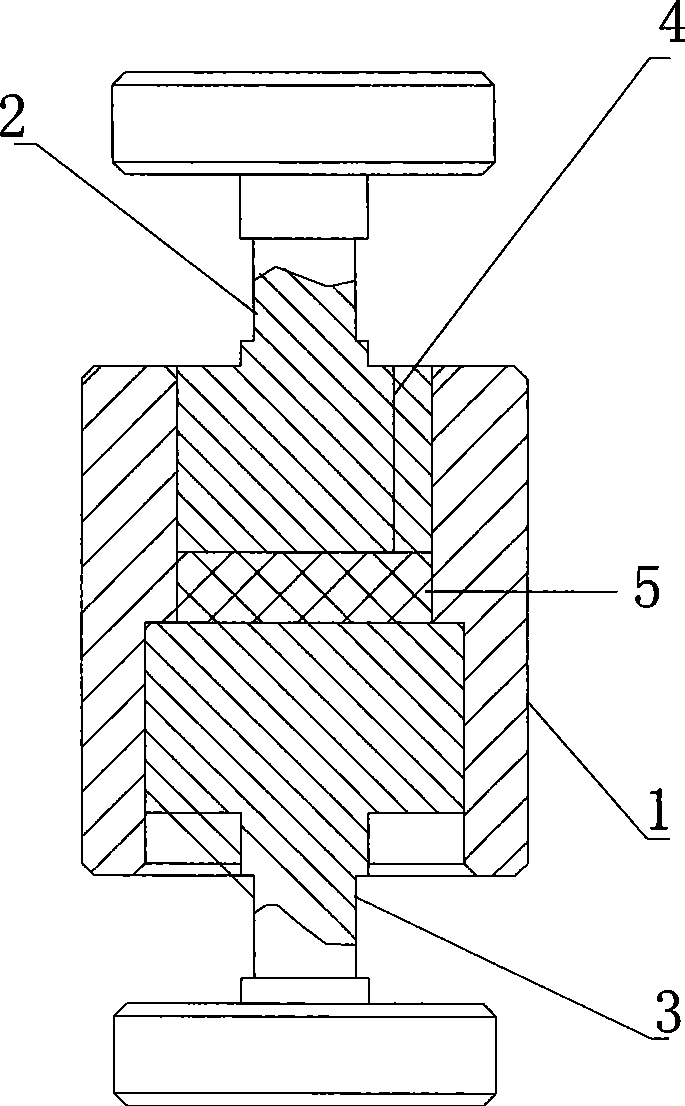

[0037] figure 1 An embodiment of the conductivity measuring device according to the invention is shown.

[0038] like figure 1 As shown, the conductivity measuring device comprises a powder container 1, an upper piston 2, a lower piston 3, a tablet press (i.e. the pressurizing device in the technical solution of the present invention, figure 1 Not shown in; pressurization range can be selected in 0-10MPa), DC resistance instrument (being the resistance measuring instrument in the technical scheme of the present invention, figure 1 not shown).

[0039] A straight cylindrical cavity is arranged in the powder container 1, and the cross section of the straight cylindrical cavity is circular; the cross sections of the upper piston 2 and the lower piston 3 are also circular; figure 1Among them, under the straight cylindrical cavity, there is a stepped hole in the powder container 1, and the radial dimension of the end of the lower piston 3 in contact with the powder to be measure...

Embodiment 2

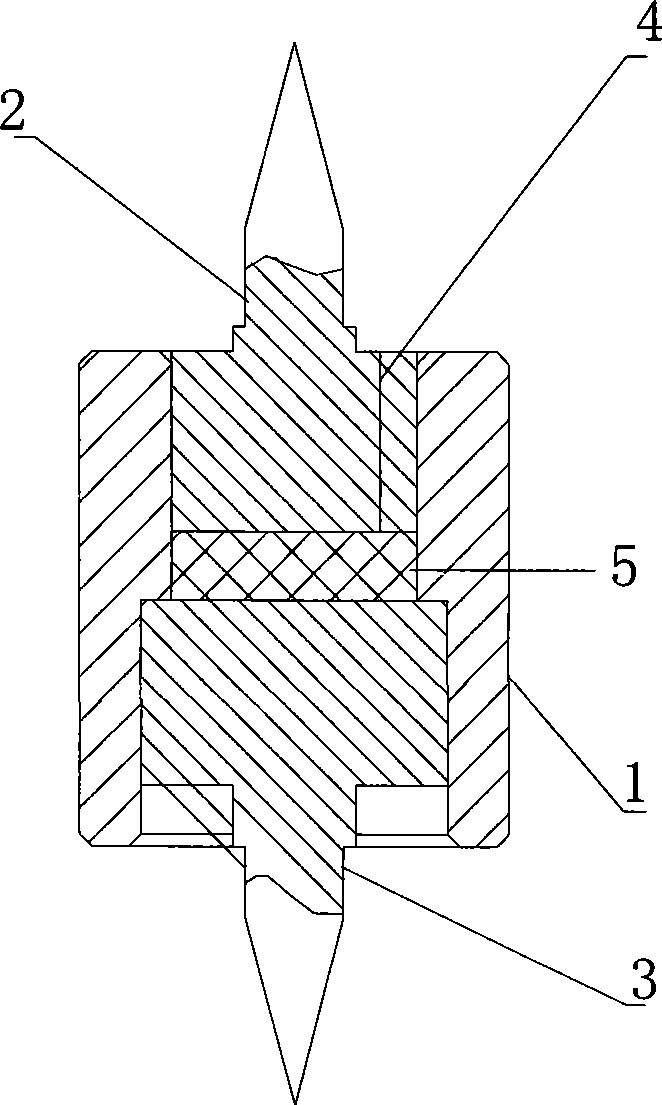

[0050] image 3 A further embodiment of the conductivity measuring device according to the invention is shown.

[0051] Compared figure 1 and image 3 The difference between the conductivity measuring device and the first embodiment is that the ends of the upper piston 2 and the lower piston 3, which are far away from the measured powder, are conical in shape.

[0052] During the test, the two test terminals of the DC resistance meter are in contact with the respective tapered ends of the upper piston 2 and the lower piston 3, so that the distance between the test terminals of the DC resistance meter and the tapered ends of the upper piston 2 and the lower piston 3 is kept smaller. The contact resistance further ensures the measurement accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com