Detaching mechanism for excess material after catsup processing

A technology of separation mechanism and tomato sauce, which is applied in application, food processing, food science, etc., can solve the problems of unsatisfactory application effect and large loss, and achieve the effect of improving product output and quality, high production efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

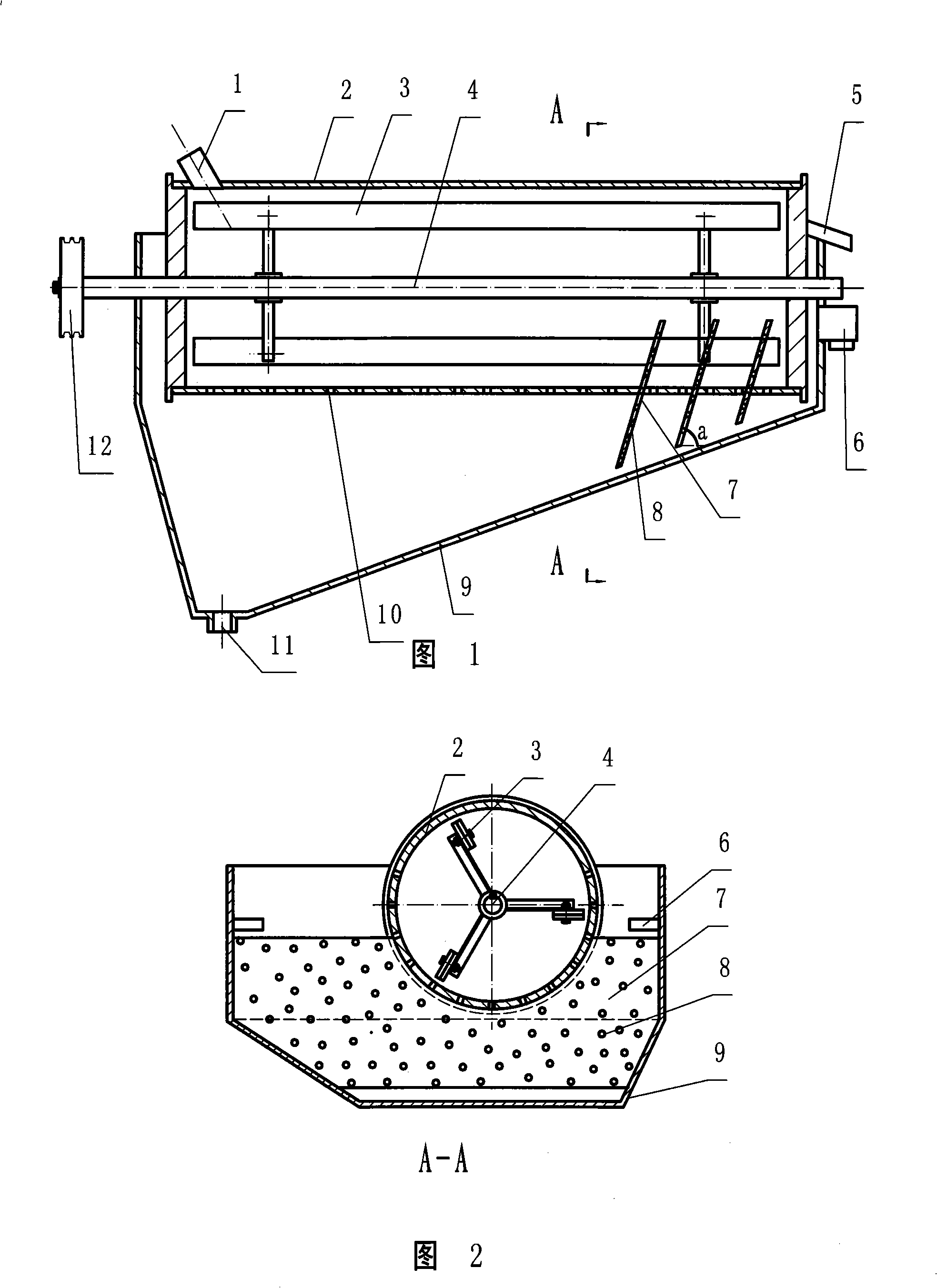

[0020] Referring to accompanying drawings 1 and 2, this embodiment includes a trommel 2 provided with a feed inlet 1 and a miscellaneous discharge port 5. The trommel 2 is provided with a transmission shaft 4 horizontally and axially, and a separation water tank is provided below the trommel 2. 9. The transmission shaft 4 is erected on the separation water tank 9 and fixedly connected with a frame. The inside of the trommel 2 is fixedly connected with the transmission shaft 4 with three scrapers 3, and the lower part of the separation water tank 9 is provided with a discharge port 11 , the top of the rear part is provided with an overflow tank 6, and the trommel 2 is placed under the liquid surface of the separation tank 9, and the depth of the bottom of the trommel 2 from the liquid level is 0.6 times of the section radius of the separation tank. A slant plate 7 is vertically arranged in the separation water tank 9, and the slant plate 7 is placed below the liquid level, and t...

Embodiment 2

[0022] Referring to accompanying drawings 1 and 2, the difference between this embodiment and embodiment 1 is that the slanting plate 7 is provided with a slanting plate screen hole 8 .

Embodiment 3

[0024] The difference between this embodiment and embodiment 2 lies in that there are two scrapers 3 fixedly connected to the transmission shaft 4 inside the trommel 2 , and the angle between the scrapers and the transmission shaft is 5°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com