Method and apparatus for dismantling circuit board with element

A technology for circuit boards and components, applied in the field of circuit board removal with components, can solve the problems of refractory, harmful and irrecoverable metal and polymer organic substances, and achieve the effect of fast cutting speed, good quality effect and blade protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

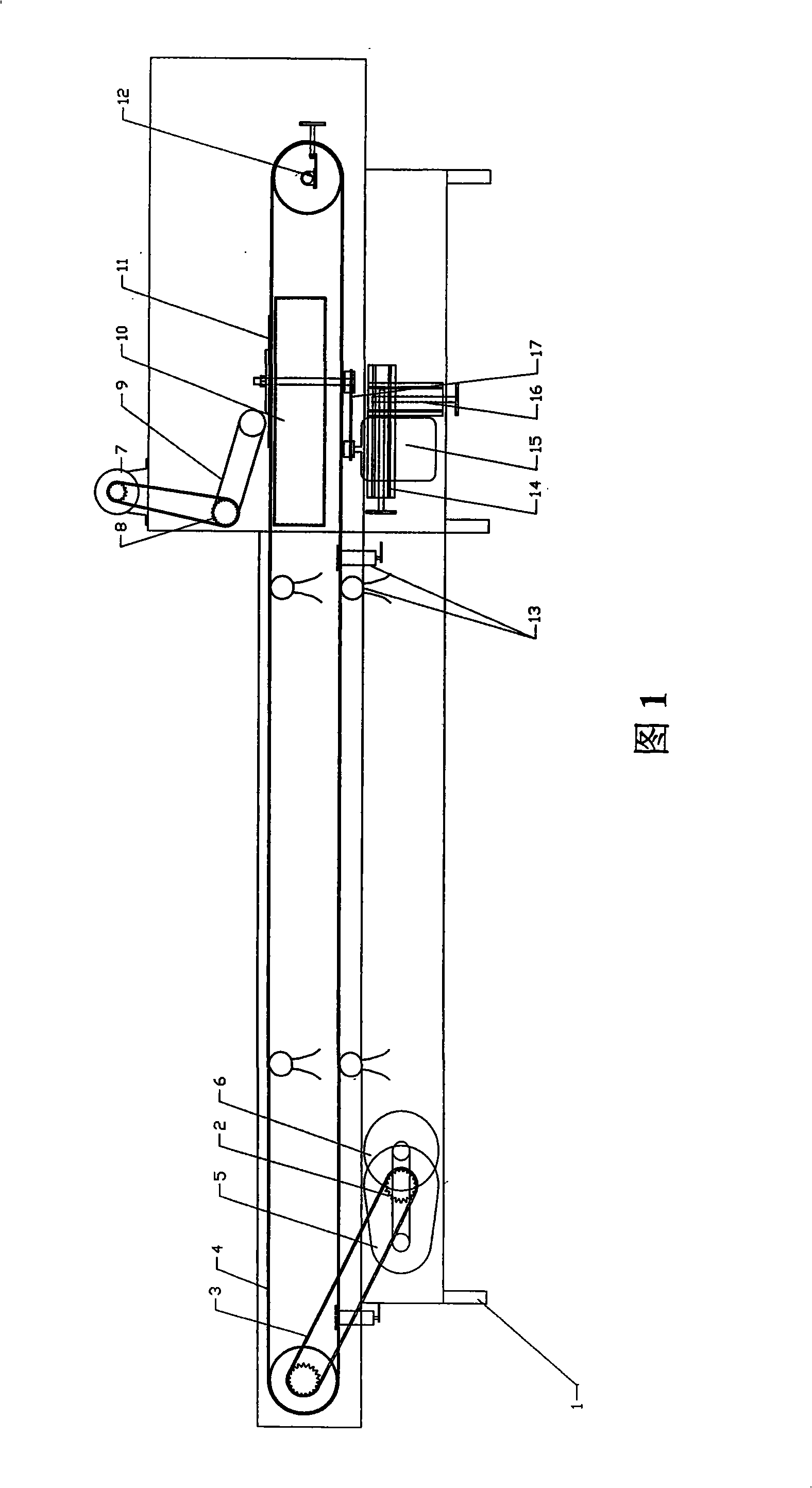

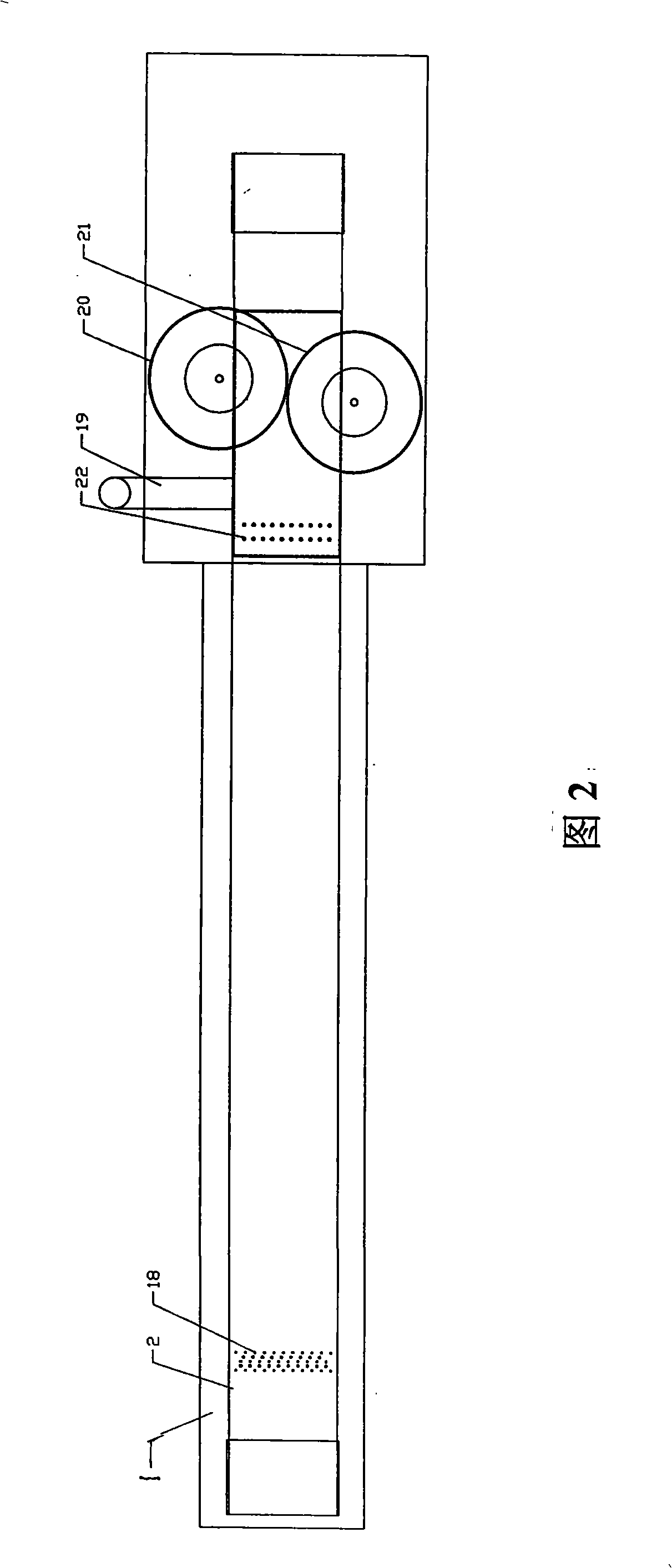

[0020] Referring to Fig. 1 and Fig. 2, the equipment for removing circuit boards with components of the present invention is composed of a frame, a transmission power device, a conveyor belt device, an auxiliary transmission device, a cutter, a cutter adjustment device, a pressing device, and a vacuum adsorption device. .

[0021] Frame 1: It is welded by square steel and steel plate, used to connect and fix the parts on it, and ensure its relative correct position.

[0022] Transmission power device: The transmission motor 6 is fixed on the frame, the belt is transmitted to the reduction box 5, and the required linear speed is achieved through the reduction box. The output end of the reduction box is the sprocket 2, which is driven by the chain 3 to the front roller (active) The conveyor belt runs; at the same time, another set of sprockets at the output end of the reduction box transmits the required linear speed to the small conveyor belt sprocket 8 through the small convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com