Printer ink supply system

A printer and ink supply technology, which is applied in printing and other fields, can solve the problems of frequent switching of ink supply pumps, shortened service life, reduced work efficiency and cost, etc., and achieves the effects of easy recycling, reduced printing costs, and reduced ink waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

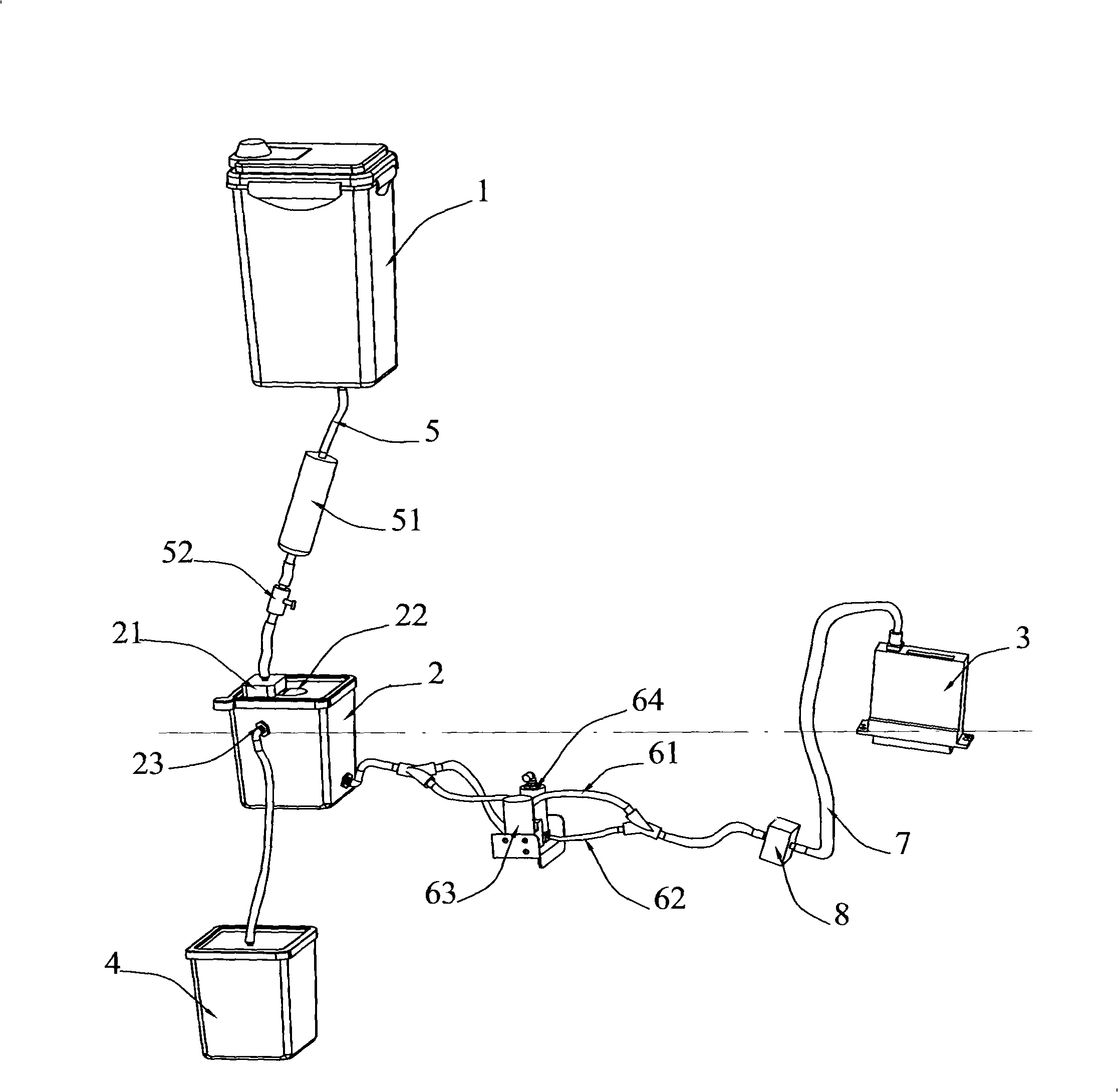

[0019] Such as figure 1 The schematic structural diagram of the ink supply system of the printer shown is mainly composed of the main ink tank 1, the auxiliary ink tank 2, the overflow bottle 4, the nozzle 3 and the ink transmission link between them. In terms of the installation position of the printer, the main ink tank 1 is installed at a position higher than the sub-ink tank 2, and is connected through the ink tube 5. The top of the sub-ink tank 2 is provided with a vent hole 22 to connect with the outside world, and the ink is automatically transferred from the main ink tank 1 through the hydraulic pressure difference. Pump to sub-cartridge 2. In order to ensure the quality of the ink and adjust the flow rate of the ink, a filter 51 and a valve 52 are respectively provided on the ink tube.

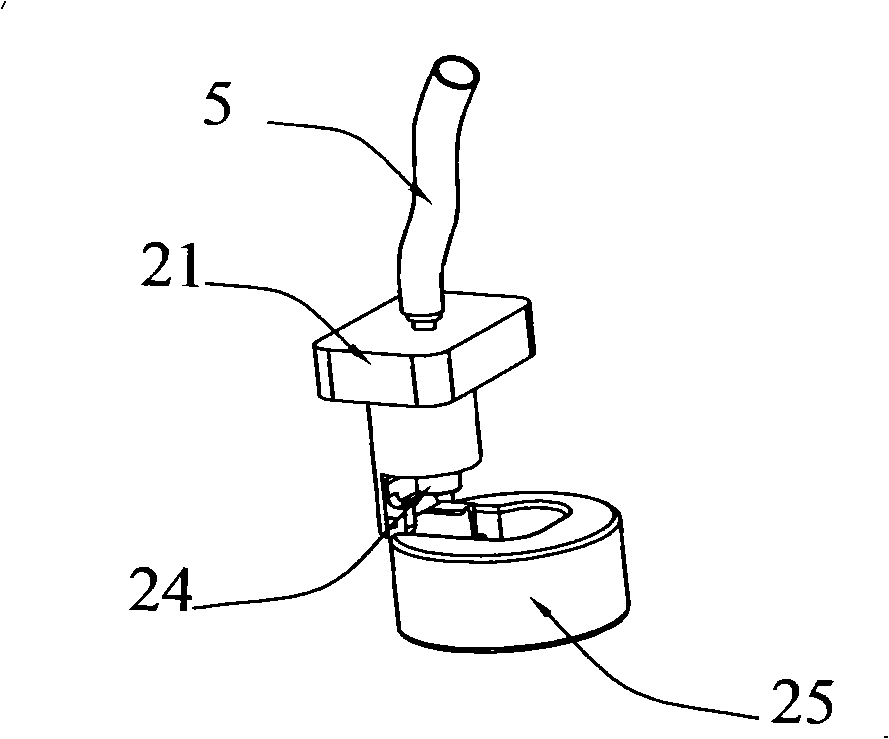

[0020] A float valve switch 21 is provided at the position where the lower end of the ink tube 5 is connected to the sub-ink box 2 to control the ink feeding of the ink tube 5, so as...

Embodiment 2

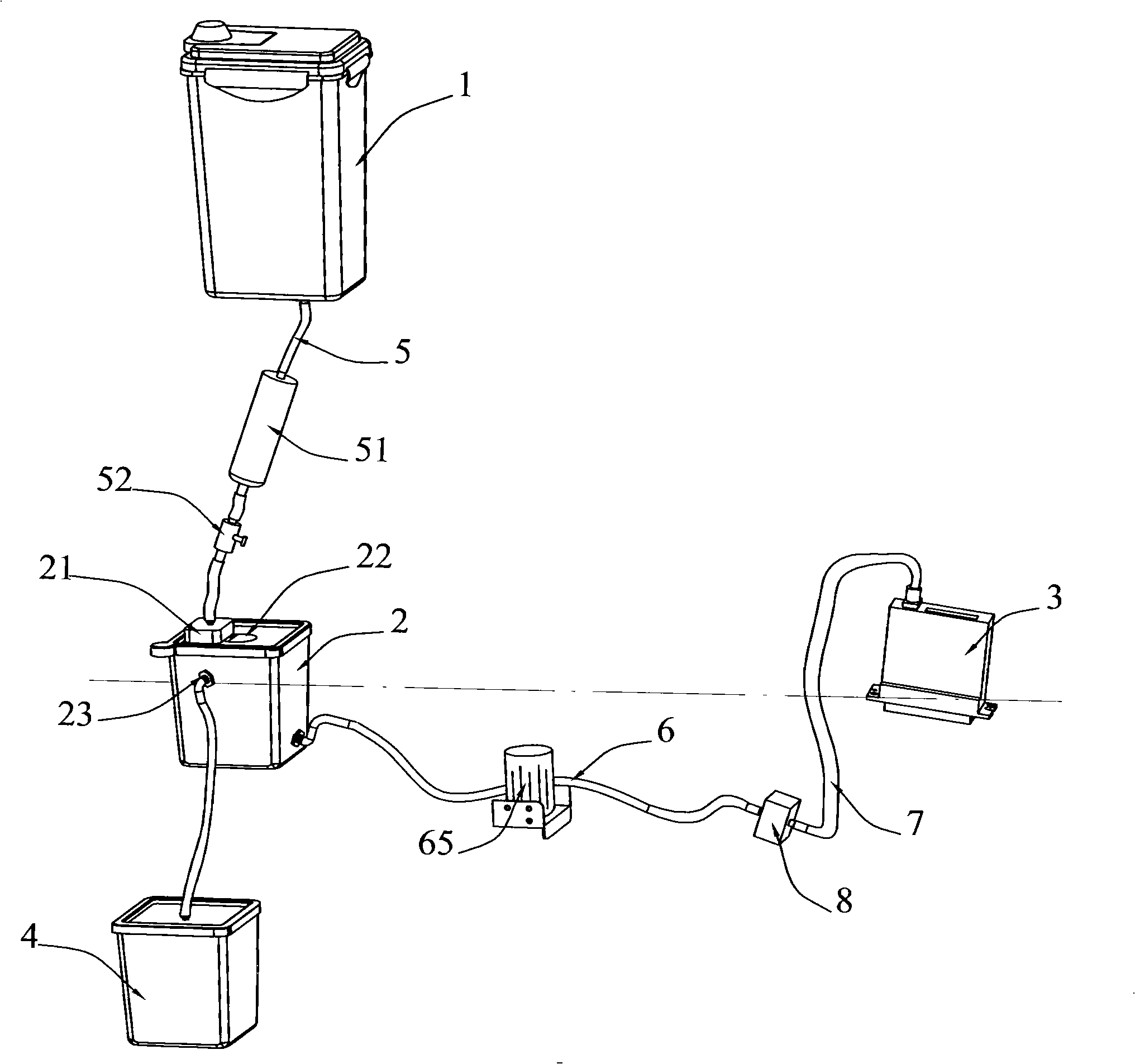

[0025] The present invention also has another embodiment on the basis of the above, as figure 2 Schematic diagram of the ink supply system of the printer shown. The difference from the previous embodiment is that the cleaning pump adopts a centrifugal pump 65, and its pipeline design is completely changed. Since the centrifugal pump 65 is connected internally when it is not working, only one ink supply pipe 65 is needed. Two functions of printing and cleaning can be realized. In the printing state, the centrifugal pump 65 is in a non-working state, and the ink flows from the sub-ink box 2 to the nozzle according to the printing requirements of the nozzle 3 . In the cleaning state, the centrifugal pump 65 is started, and the ink is sucked out from the sub-ink box 2 by centrifugal action, and sprayed out from the nozzle 3 to realize the cleaning of the nozzle 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com