Method for printing transfer printing film and forming pattern on printing stock

A technology for transfer film and substrate, which is applied in the process of producing decorative surface effects, decorative arts and other directions, which can solve the technical requirements of transfer film, high equipment requirements, inability to realize personalized production, and difficult control of workers' operation. and other problems to achieve the effect of enhancing elasticity and adhesion fastness, satisfying individualization and industrialization, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

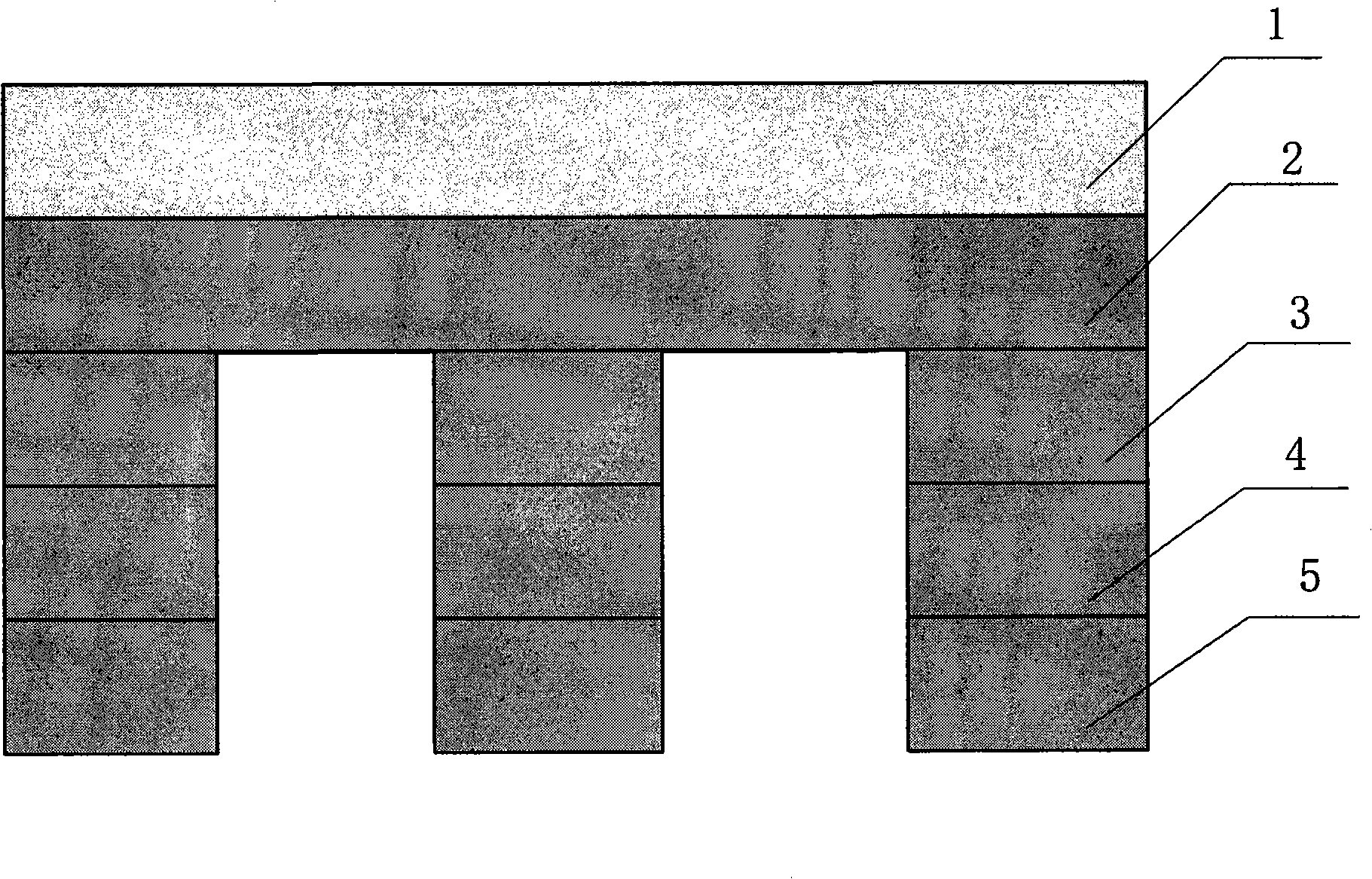

[0010] according to figure 2 As shown, the transfer film in the prior art is composed of a transfer carrier film 1, a release layer 2, a color layer 3, a background layer 4, and a hot melt adhesive layer 5. The release layer 2 can be partially coated on the transfer carrier film 1 or coated on the transfer carrier film 1 as a whole. The color layer 3, the background layer 4 and the hot-melt adhesive layer 5 are only printed on the parts with pictures and texts. Color layer 3 should be printed by screen printing, gravure printing, or offset printing. No matter which printing method is adopted for graphic color layer 3, a negative film must be produced and then plated.

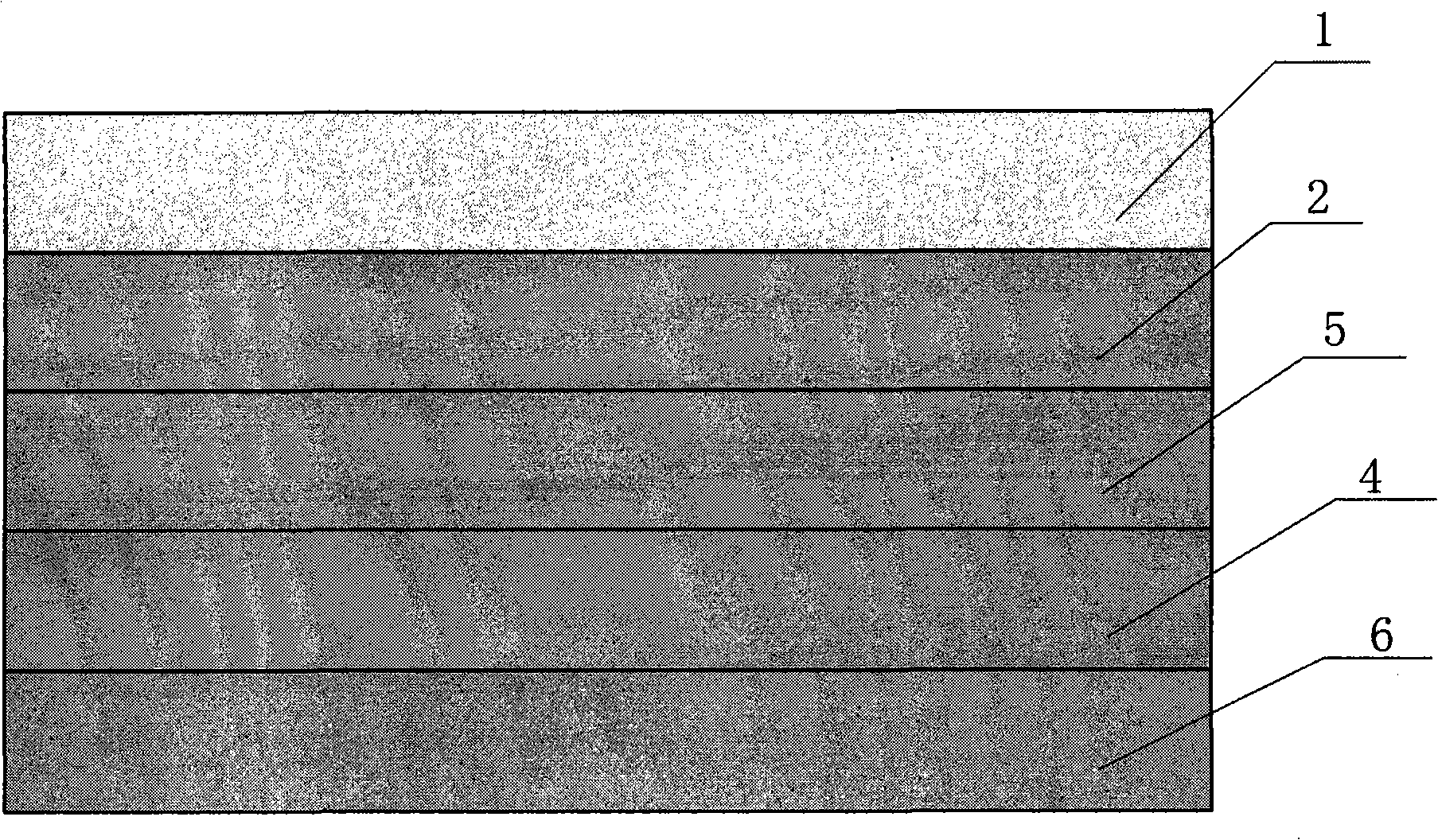

[0011] according to figure 1 As shown, the printing transfer film of the present invention includes a transfer carrier film 1, a release layer 2, a hot melt adhesive layer 5 and a printable layer 6. The transfer carrier film 1 is entirely covered with a release layer 2, and The molding layer 2 is entirely covered w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com