Production of glucosinolates from agricultural by-products and waste

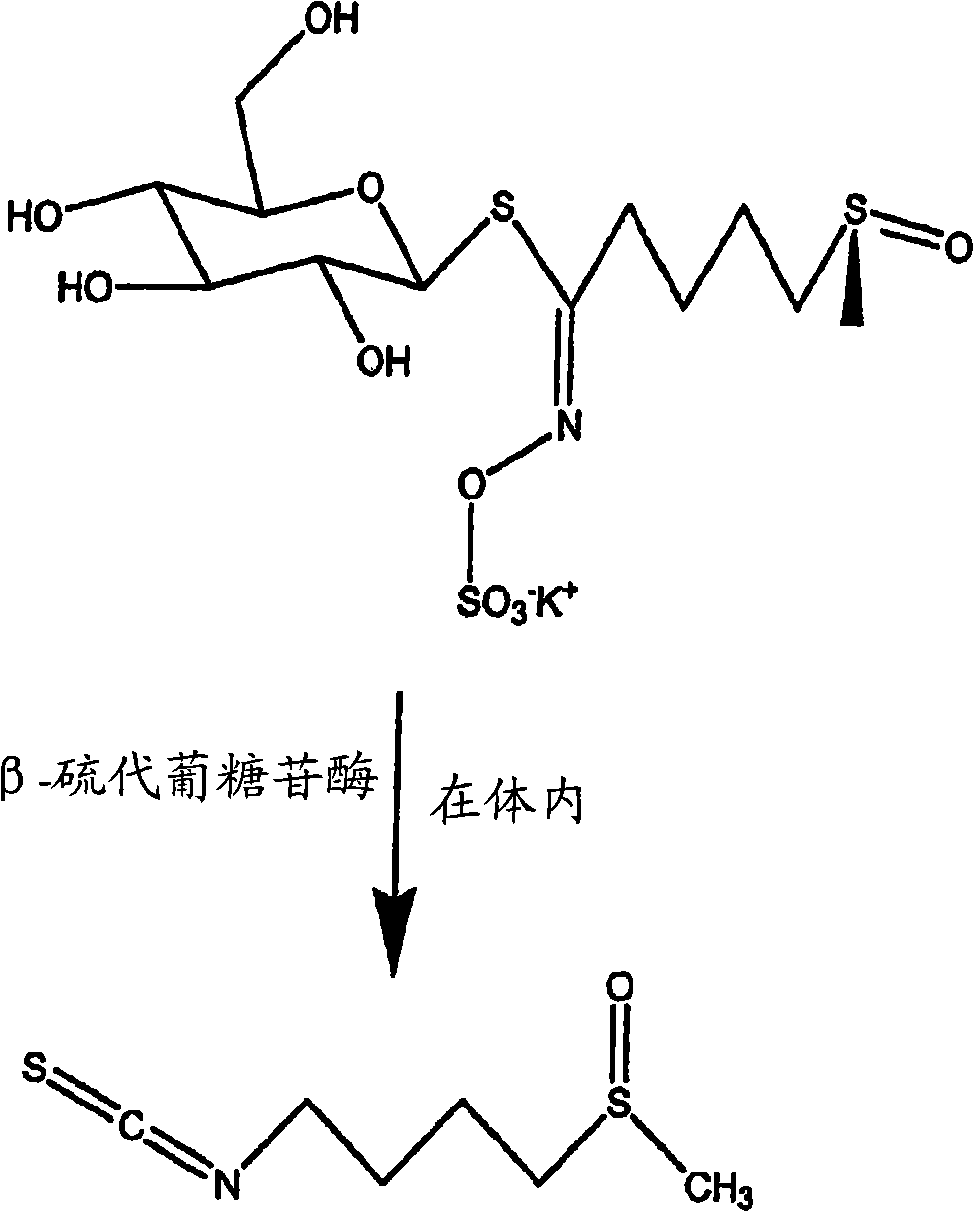

A technology of glucosinolates and mixtures, applied in the field of glucoraphanin, can solve the problems of insufficient recognition of the health potential of glucosinolates, high costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

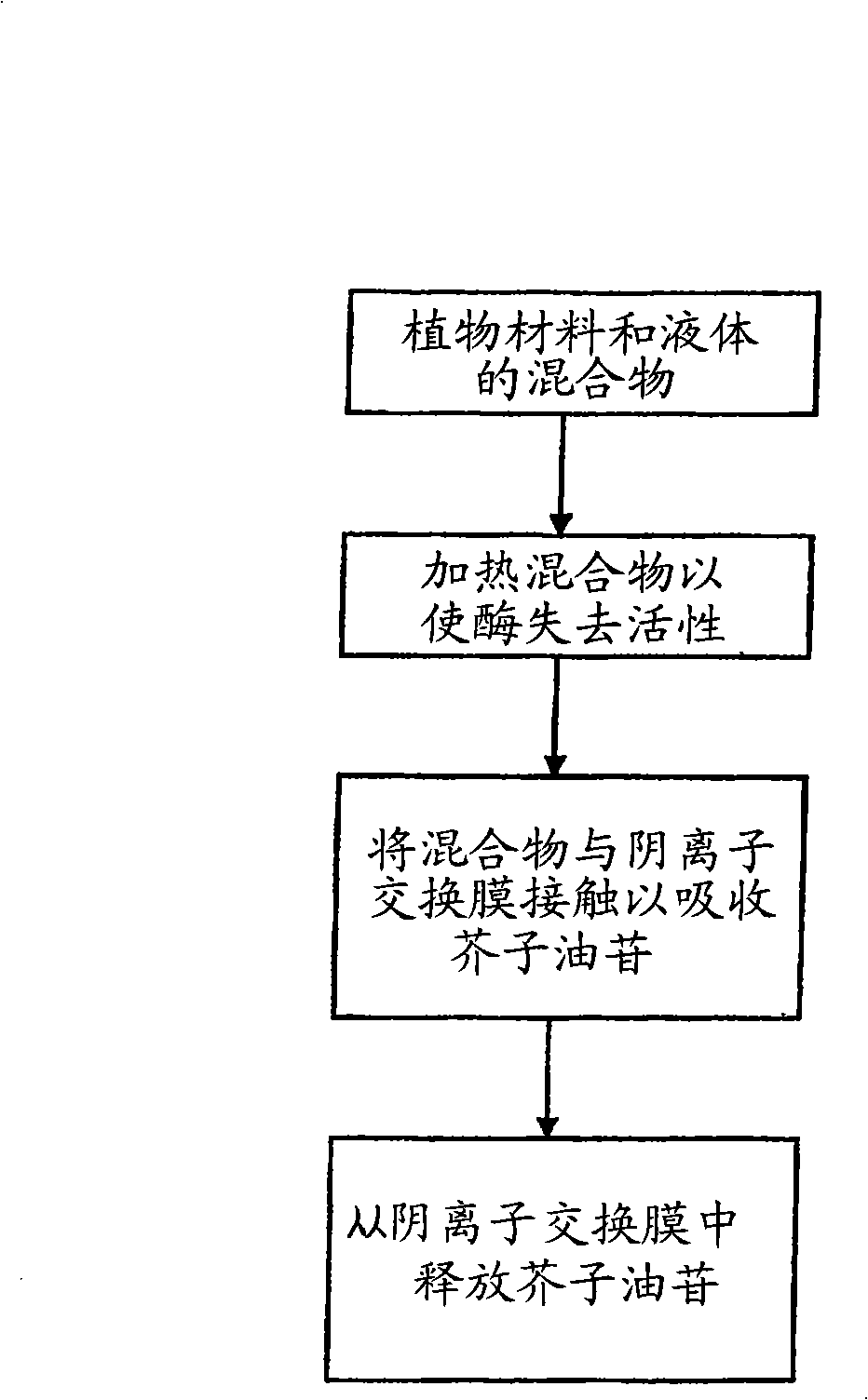

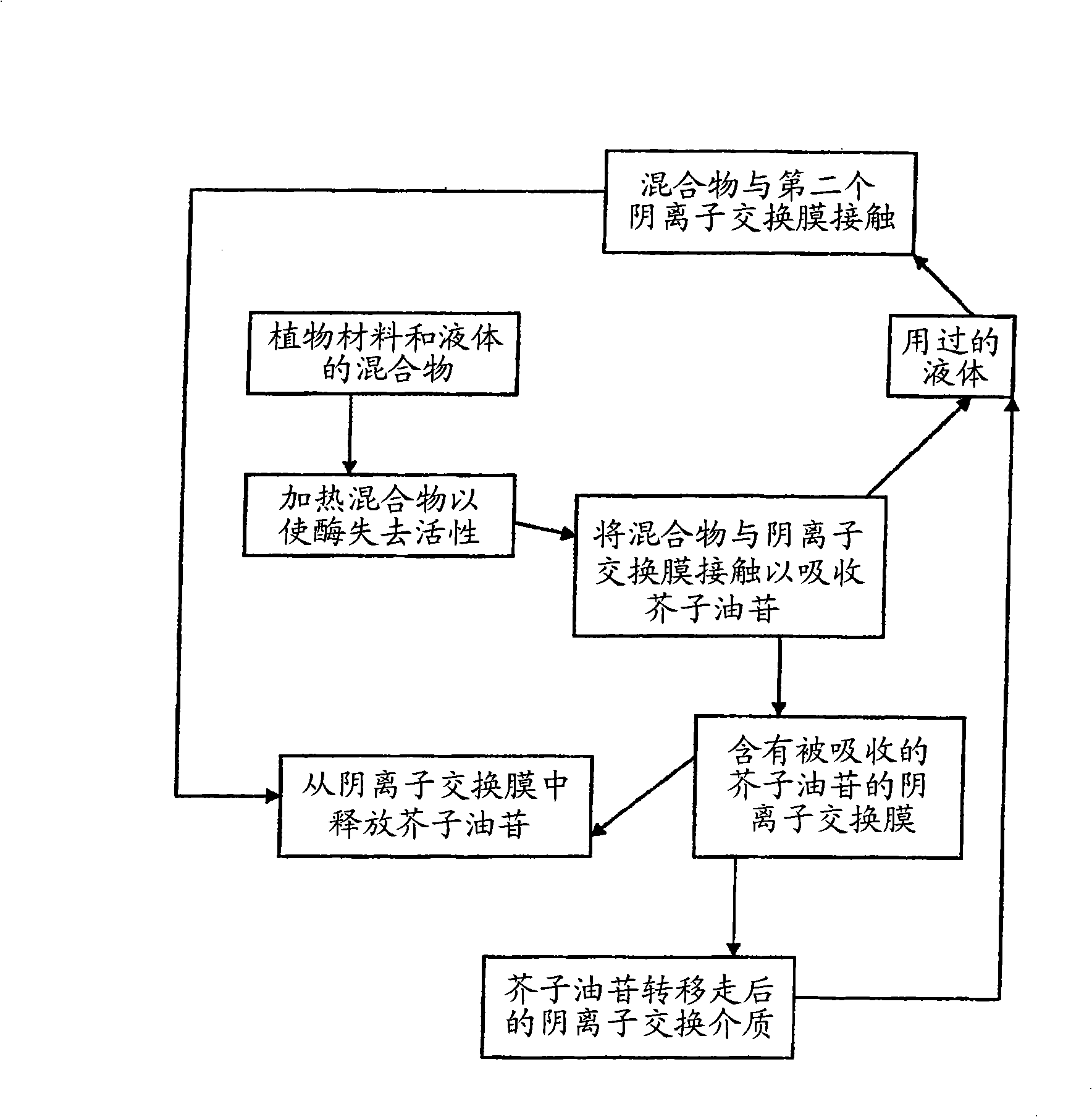

Method used

Image

Examples

Embodiment 1

Example 1 : Glucosinolates from cauliflower seeds

[0045] 15 g of cauliflower seeds were degreased by n-hexane extraction, and ground into powder and passed through a No. 18 sieve. The pulverized and defatted cauliflower seeds were added to 1500 ml of deionized water to form a mixture. The mixture was boiled for 5 minutes to inactivate β-thioglucosidase in the seeds. The total volume of the mixture was brought to 4500 ml by adding deionized water. One square foot of Electropure Excellion Anion Exchange Membrane Heterogeneous Strong Basic, Type 1, Model 1-200 (Snowpure, LLC in San Clemente, CA), was suspended in the continuously stirred mixture at 5°C for 24 hours. After extraction, the anion-exchange membrane was rinsed briefly with deionized water, and the membrane was placed in a stirred tank containing 4500 ml of 1N potassium chloride solution at 5°C for 4 hours to release glucosinolates from the anion-exchange membrane. Glucoraphanin concentrations in aqueous media we...

Embodiment 2

Example 2 : Glucosinolates from cauliflower florets

[0048] With the cauliflower floret that 150g pulverizes drying, repeat the process of embodiment 1. The cauliflower florets were ground to a powder to pass through a No. 18 sieve. The result of this process is that greater than 80% of the glucosinolates are recovered.

Embodiment 3

Example 3 : Plant-derived glucosinolates

[0049] The procedure of Example 1 was repeated by using 1 kg of freshly harvested cauliflower leaves and stems. Cauliflower leaves and stems were steamed for 20 minutes to reduce β-thioglucosidase activity. The cauliflower leaves and stems are then mashed. This process glucosinolate extraction result is similar with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com