A kind of pasty fiber art paint and preparation method thereof

A fiber and art technology, applied in the preparation of paste fiber art paint, in the field of paste fiber art paint, can solve problems such as cracking, and achieve the effect of no burning, no irritating odor, and good decorative coating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

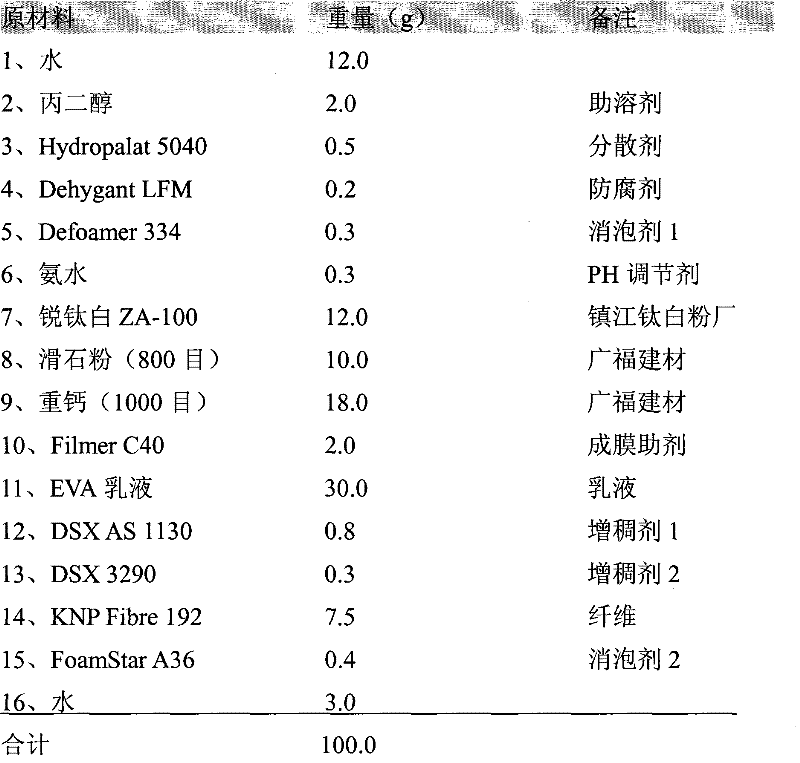

[0037] A paste-like fiber art paint has the following components:

[0038]

[0039] Among them, dispersant Hydropalat 5040, preservative Dehygant LFM, defoamer 334 and FoamStar A36, film-forming aid Filmer C40, thickener DSX AS 1130 and DSX 3290, and fiber KNP Fibre 192 are all provided by Haichuan Chemical. EVA emulsion is provided by Beijing Dongfang Chemical Factory. The main component of film-forming aid Filmer C40 is alcohol ester-12.

[0040] Preparation steps of paste fiber art paint:

[0041] 1. Add components 1-6 in turn, add components 7-9 while stirring, disperse and grind in a disperser with a rotational speed of 2500 rpm until the fineness is less than 40 μm;

[0042] 2. Add components 10 and 11 under low-speed stirring, add components 12 and 13 after stirring evenly, and adjust the viscosity to 115KU;

[0043] 3. Add component 14 under high-speed stirring, and after stirring evenly, add components 15 and 16, and stir evenly to obtain a paste-like fiber art ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com