Real silk and real silk intimating digit printing process

A technology of digital printing and imitation silk, which is applied in the printing process, printing, printing of special varieties of printed matter, etc., can solve the problems of poor color reproduction and low color fastness, and achieve the effect of speeding up the affinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

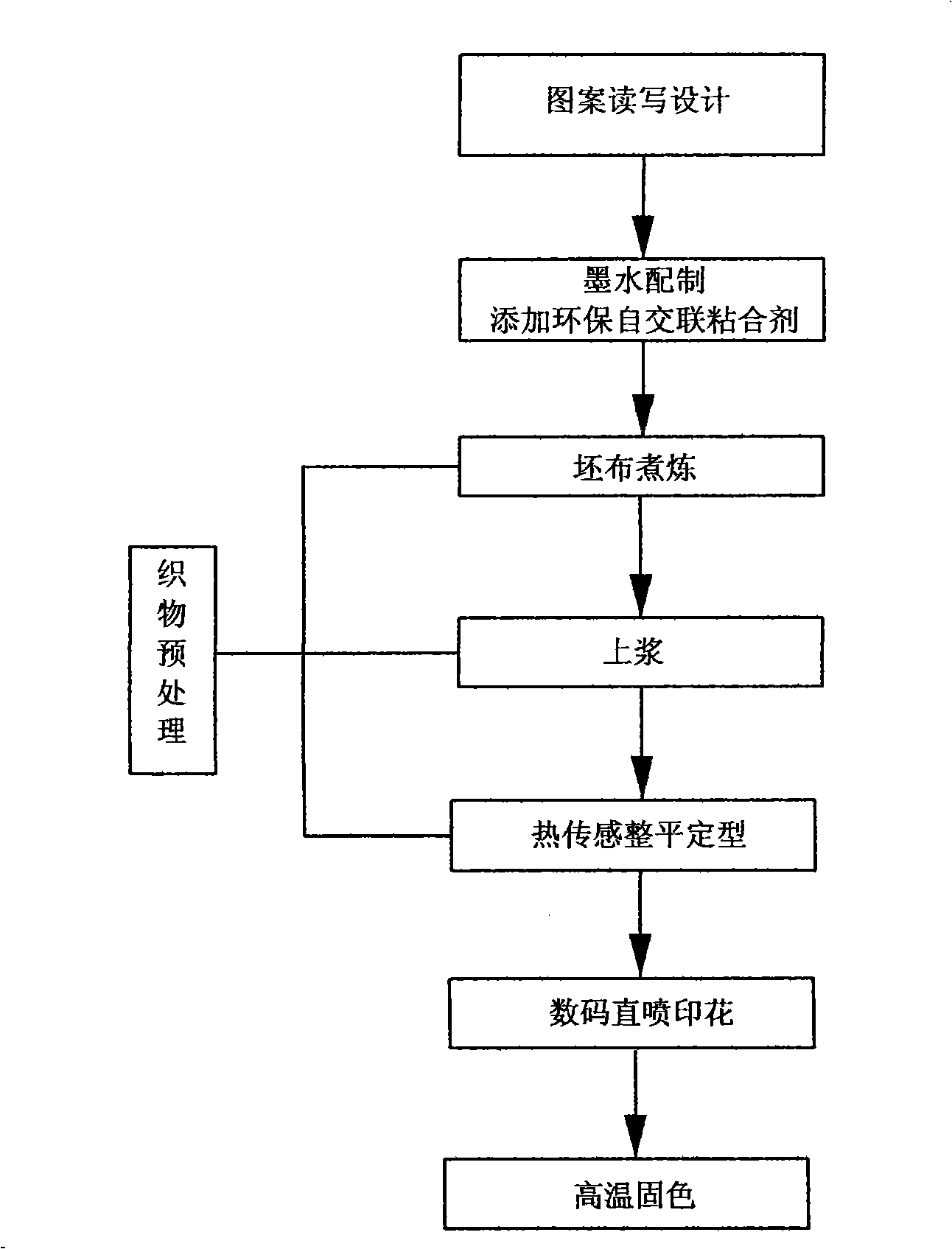

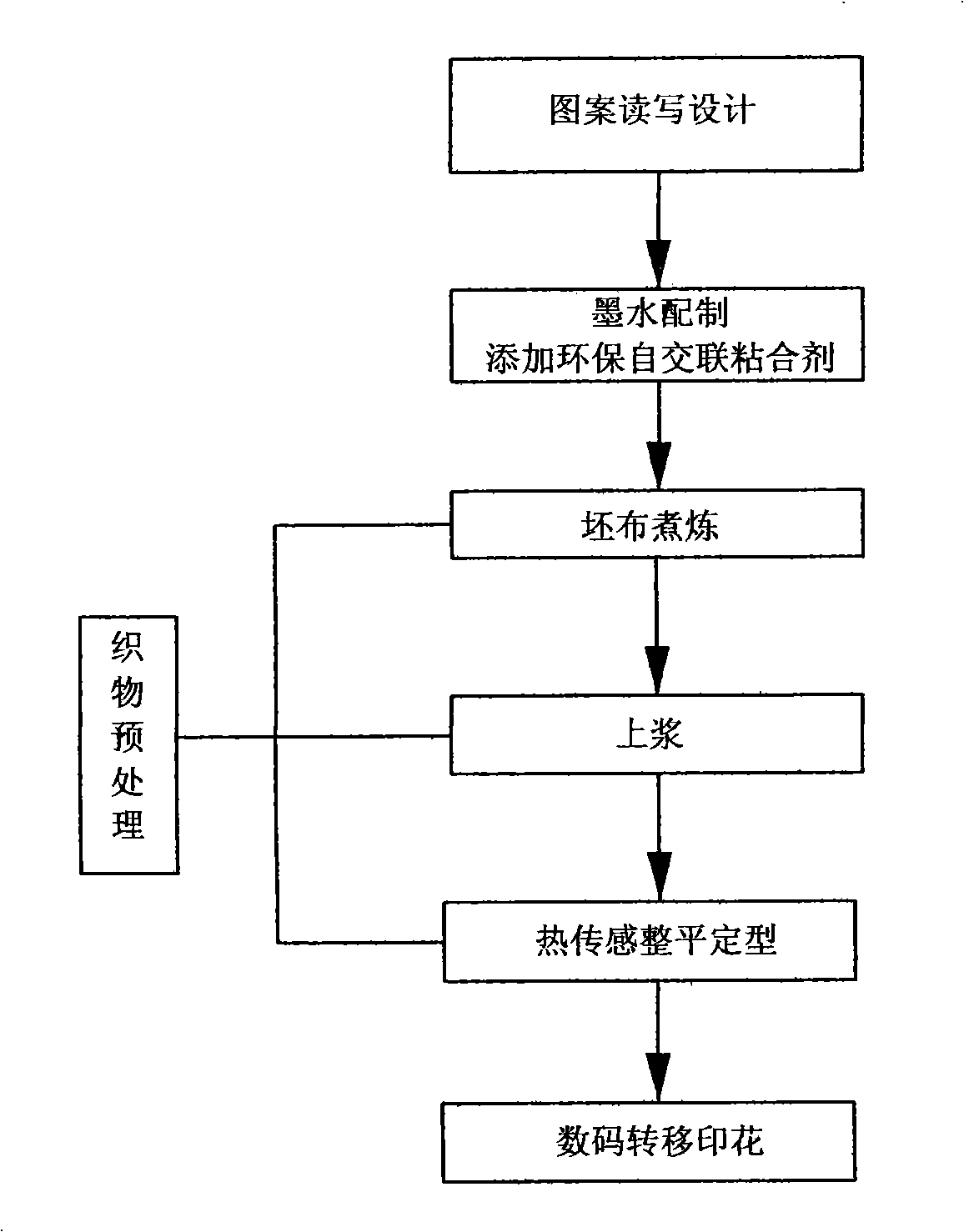

[0030] refer to figure 1 The process flow of the present invention shown is as follows: pattern reading and writing design→ink preparation→fabric pretreatment→digital direct printing:

[0031] 1. Pattern reading and writing design: input the pattern required for printing into the computer and save it.

[0032] 2. Ink preparation: the ink required by the invention is prepared by adding an environmentally friendly self-crosslinking adhesive at 3-5% by weight of the ink.

[0033] 3. Fabric pretreatment: After the gray cloth is boiled, the prepared slurry is used to sizing the gray cloth. The composition of the slurry is as follows:

[0034] Synthetic dragon gum 2~3%

[0035] Sodium alginate 3~5%

[0036] Urea 8~15%

[0037] Baking soda 2~5%

[0038] Yuanming powder 2~5%

[0039] The balance is water

[0040] Put the above components into a beater after mixing, and beat for 1 to 1.5 hours until the slurry is uniform.

[0041] After the sizing process, the blank is pressed ...

Embodiment 2

[0044] Processing step is the same as embodiment 1, and difference is that heat setting pressure is 2.5kgf / cm 2 , The heating temperature is 250°C.

Embodiment 3

[0046] Processing step is the same as embodiment 1, and difference is that heat setting pressure is 3kgf / cm 2 , the heating temperature is 200°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com