Method for detecting cutting fluid concentration during use

A detection method and technology of cutting fluid, applied in the field of detection of cutting fluid concentration in use, can solve problems such as inability to accurately measure the effective concentration of cutting fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

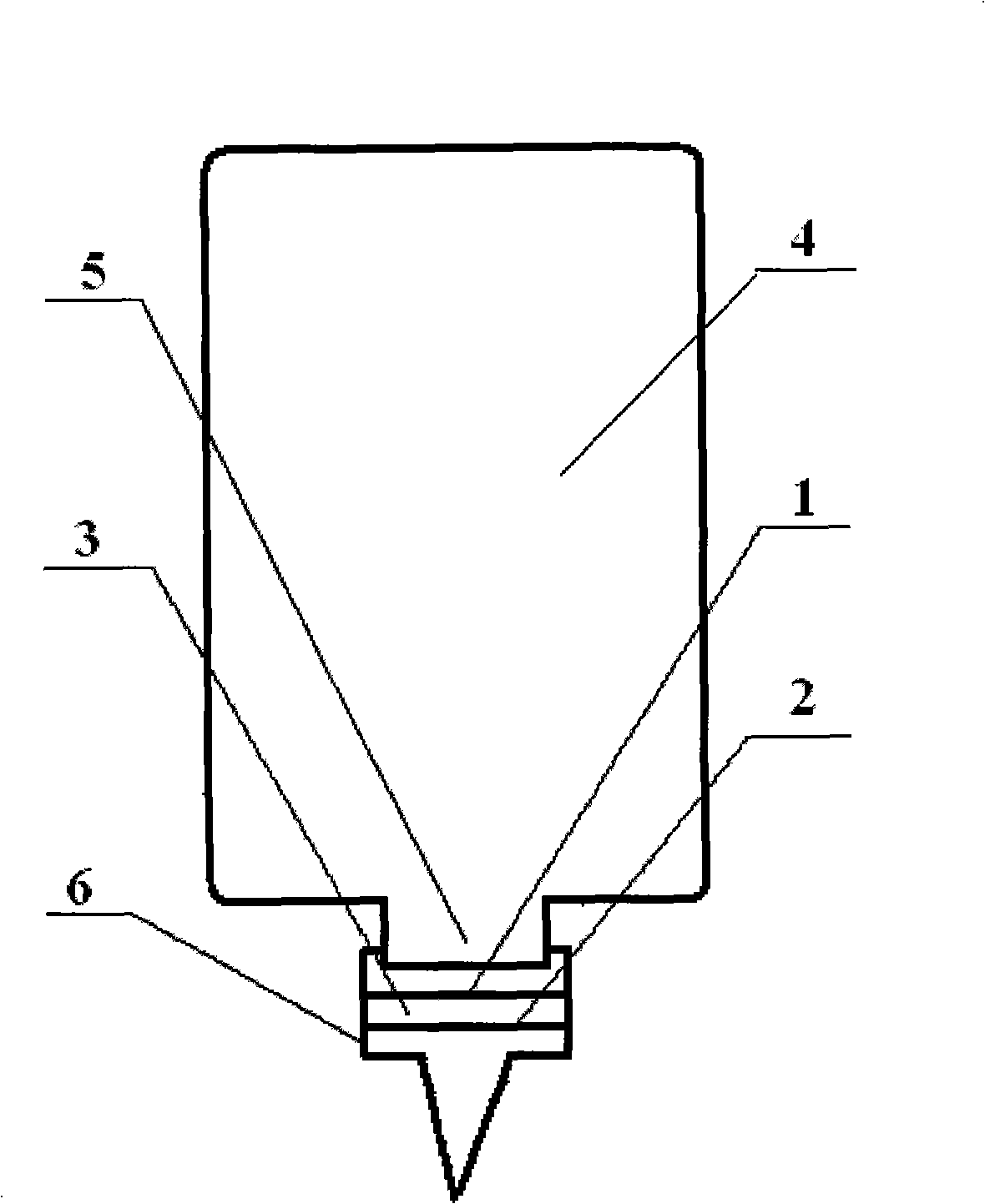

[0029] Add cutting fluid of known concentration to figure 1 In the sample preconditioner shown, then measure its refractive index with a refractometer, so as to convert the cutting fluid concentration. The conditions of each layer of filter membrane and adsorbent in the sample outlet of the preprocessor are shown in Table 1, and the test results are shown in Table 2.

[0030] Table 1 Filter membrane structure of preconditioner

[0031] Example

first filter membrane

Adsorbent

second filter membrane

third filter membrane

The fourth filter membrane

1

Qualitative filter paper

-

3 micron microporous membrane

-

-

2

Quantitative filter paper

5 micron microporous membrane

-

-

3

Qualitative filter paper

-

8 micron microporous membrane

3 micron microporous membrane

-

4

Qualitative filter paper

-

1.2 micron microporous membrane ...

Embodiment 9~16

[0036] The dirty cutting fluid was taken from the factory site, treated with the sample preprocessor of Example 2, and then its concentration was measured with a refractometer. The results are shown in Table 3.

[0037] Table 3 Test results of cutting fluid used on site

[0038] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com