Lamp tube exhauster

A technology of exhaust machine and lamp tube, which is applied in the direction of electric tube/lamp exhaust, electrical components, discharge tube/lamp manufacturing, etc. It can solve the problem of increasing the cost of lamp tubes, increasing power consumption, increasing the speed of vacuum pumps and exhausting Quantity and other issues, to achieve the effect of guaranteed quality, convenient installation and maintenance, and good power saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

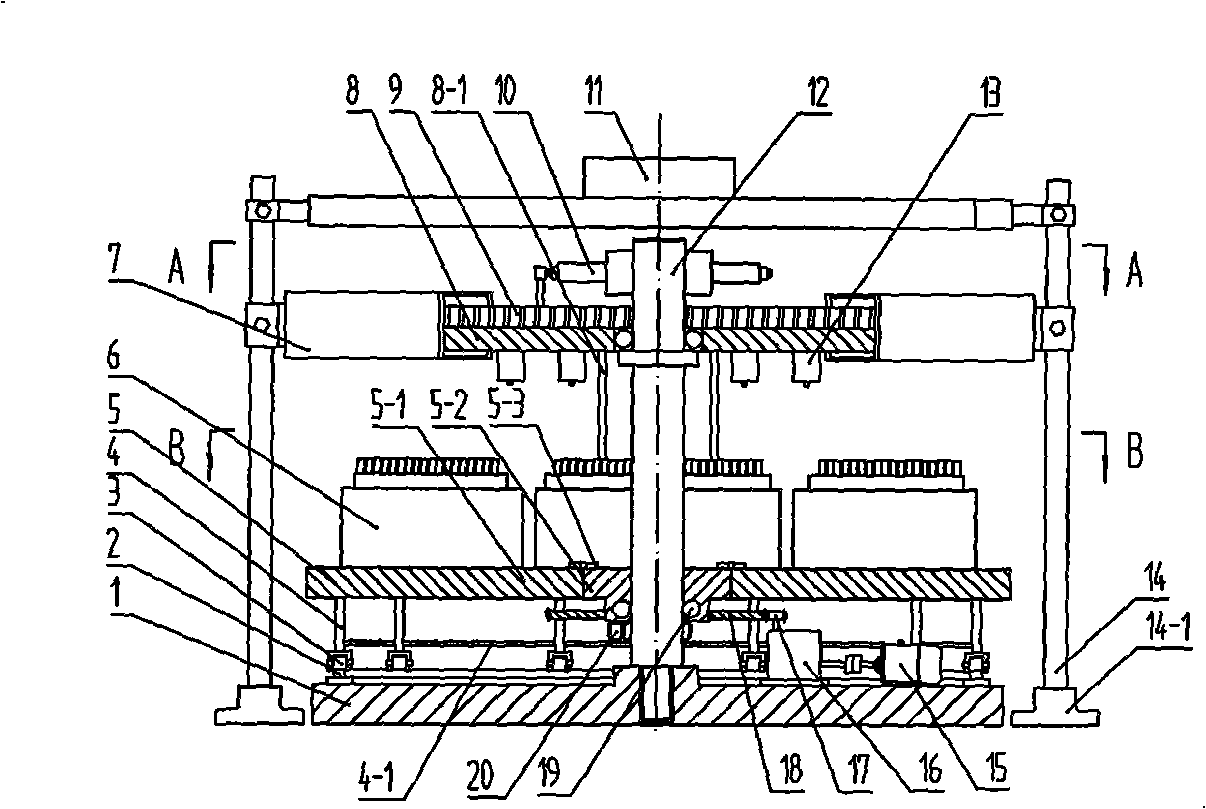

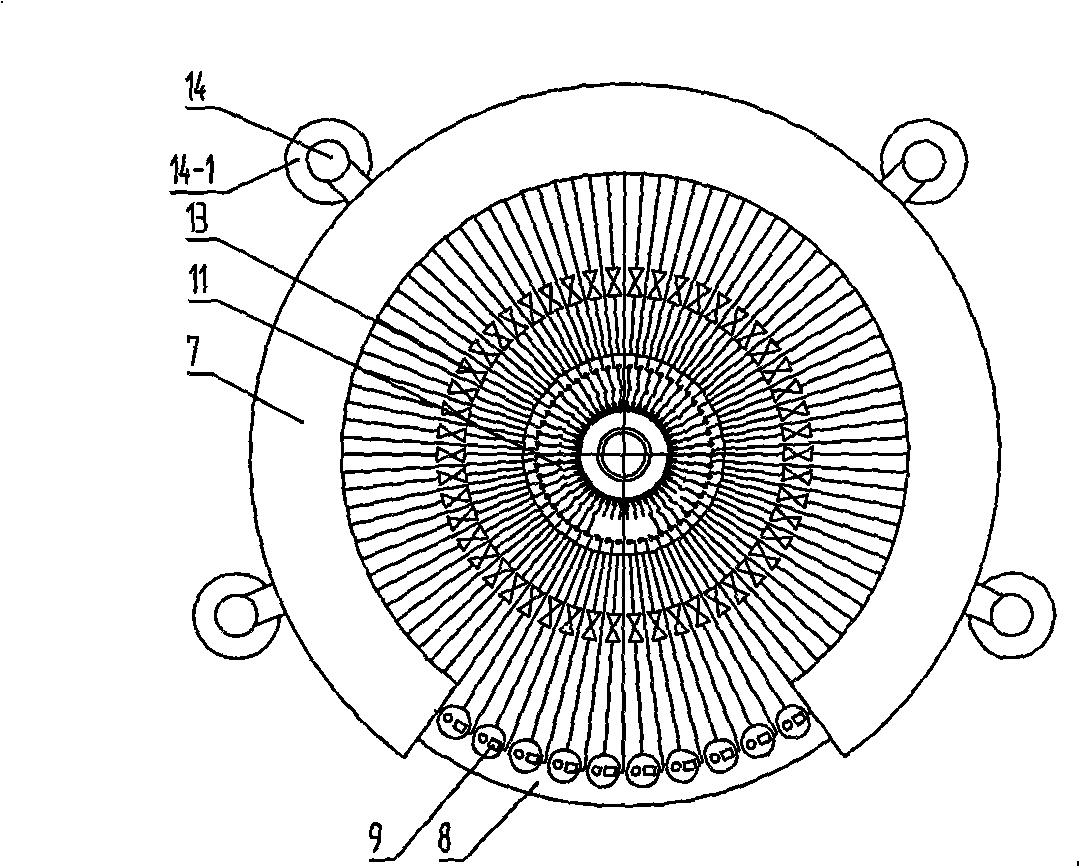

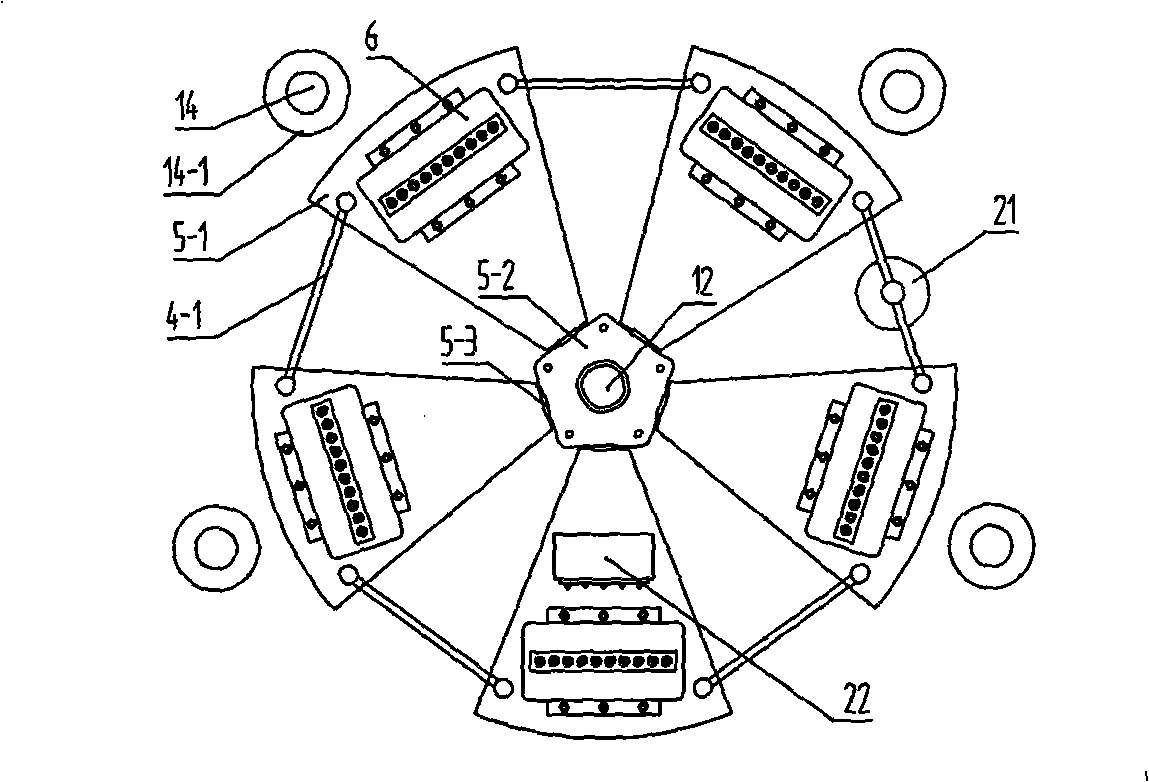

[0016] Such as figure 1 , 2 , shown in 3: a lamp tube exhaust machine, including a base plate 1, a column 12 vertically fixed on the upper end of the base plate 1, a disc-shaped working disc 8 that is installed on the upper part of the base plate 1 and can rotate, and is set on the periphery of the working disc 8 A large oven 7, a plurality of lamp sockets 9 evenly distributed around the upper end of the work plate 8, a switch assembly 10 for intermittently supplying power to the lamp sockets 9, a cooling device 11 for supplying water to the lamp holders, multiple lamp tubes for charging and exhausting A vacuum pump 6, a solenoid valve unit 13 and an inert gas tank 21; the oven 7 is a rectangular ring box, the outside of which is installed on the ground through a plurality of outer columns 14 and a base 14-1, and the fan-shaped gap made at the front end of the oven 7 It is an operating station; it is characterized in that: the vacuum pump 6 is a multi-chamber vacuum pump, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com