Low-temperature preparation method of titanium dioxide photocatalyst co-doped with carbon, nitrogen and sulphur

A technology of carbon, nitrogen, sulfur and titanium dioxide, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., to achieve enhanced response, improved utilization, and mild reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Drop titanium tetrachloride into 15mL deionized water at 2°C to form a titanium-containing aqueous solution with a concentration of 0.25 mol / liter, then add L-cysteine to make the molar ratio of cysteine to titanium tetrachloride The ratio is 0.25:1; the obtained solution is placed in a 20mL reactor, and subjected to hydrothermal reaction at 180°C for 24 hours, and the obtained hydrothermal reaction product is washed with water and ethanol, separated, and dried at 50°C to obtain a light gray powder.

Embodiment 2

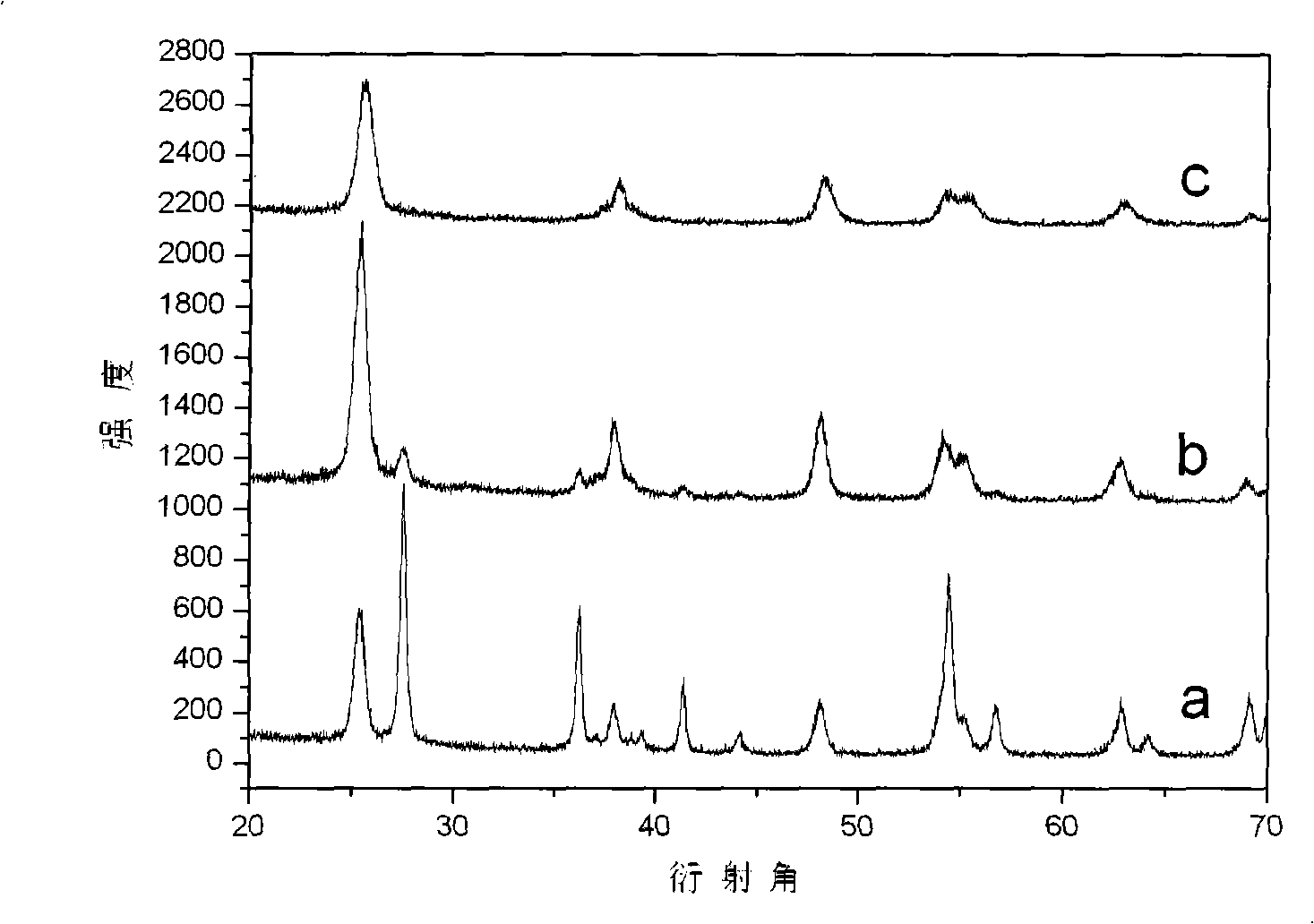

[0026] Drop titanium tetrachloride into 15mL deionized water at 2°C to form a titanium-containing aqueous solution with a concentration of 1.5 mol / liter, then add L-cysteine to make the molar ratio of cysteine to titanium tetrachloride The ratio is 2:1; the obtained solution is placed in a 20mL reactor, and subjected to hydrothermal reaction at 180°C for 24 hours, and the obtained hydrothermal reaction product is washed with water and ethanol, separated, and dried at 50°C to obtain a light gray powder. The XRD diffraction pattern of the powder product is shown in figure 1 in b.

Embodiment 3

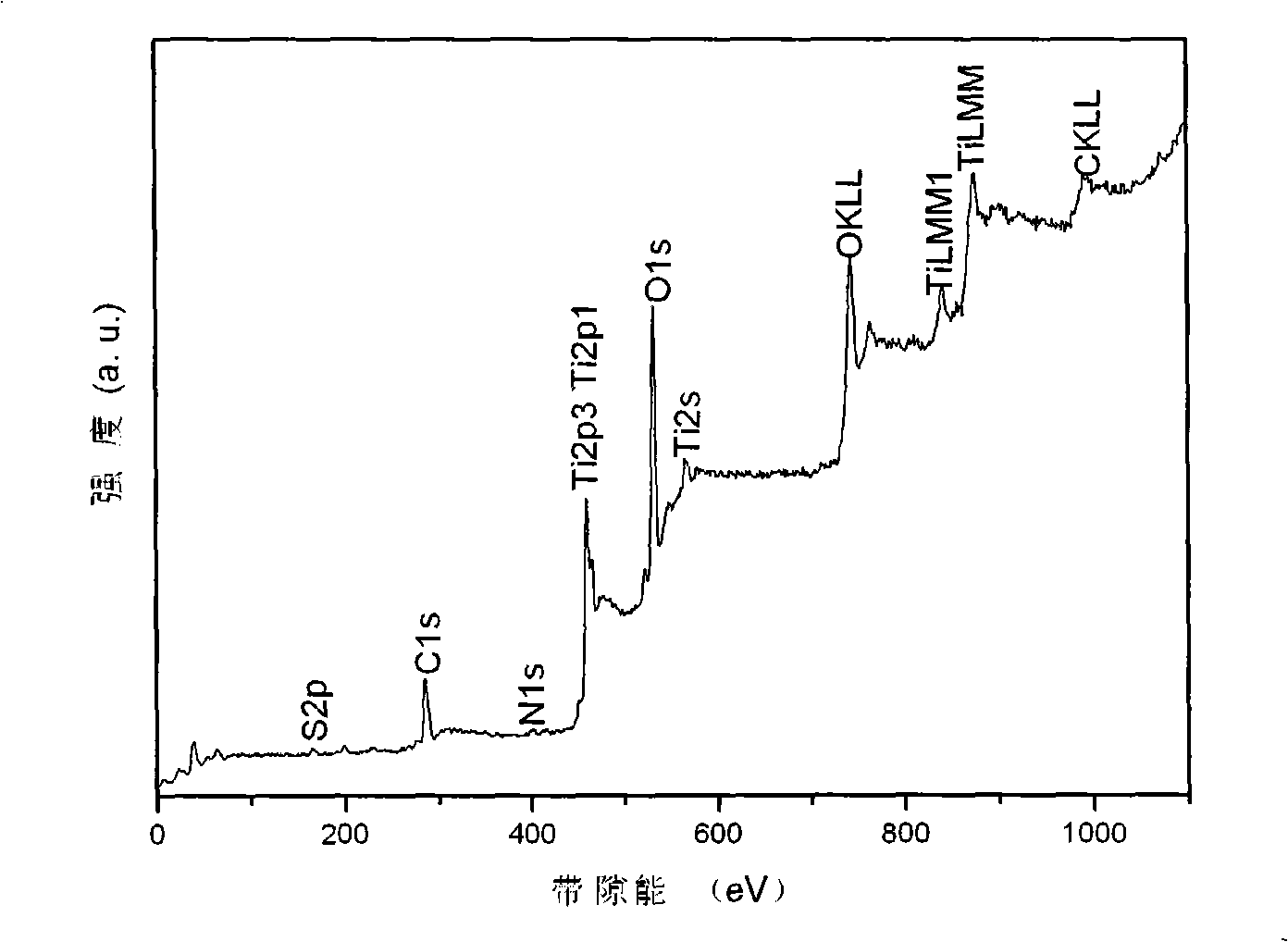

[0028] Titanyl sulfate was dropped into 15mL deionized water at 3°C to form a titanium-containing aqueous solution with a concentration of 5 mol / liter, and then L-cysteine was added so that the molar ratio of cysteine to titanium tetrachloride was 3:1; the obtained solution was placed in a 20mL reactor, and hydrothermally reacted at 180°C for 24 hours, and the obtained hydrothermally reacted product was washed with water and ethanol, separated, and dried at 50°C to obtain a light gray powder. The XRD diffraction pattern of the powder product is shown in figure 1 In c; the XPS full spectrum of the product is shown in figure 2 , the mass percent of each element in the product is C: 34.3%; O: 47.5%; Ti: 14.5%; N: 2.1%; S: 1.6%. The SEM image of the product is shown in image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com