Numerical control generating gear grinding machine and numerical control device thereof and driving method

A technology of numerical control device and gear grinding machine, which is applied in the direction of digital control, components with teeth, gear teeth, etc., can solve the problems of damaged gears to be processed, limited gear specifications, low reliability and versatility, etc. The effect of reducing the probability and improving the machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

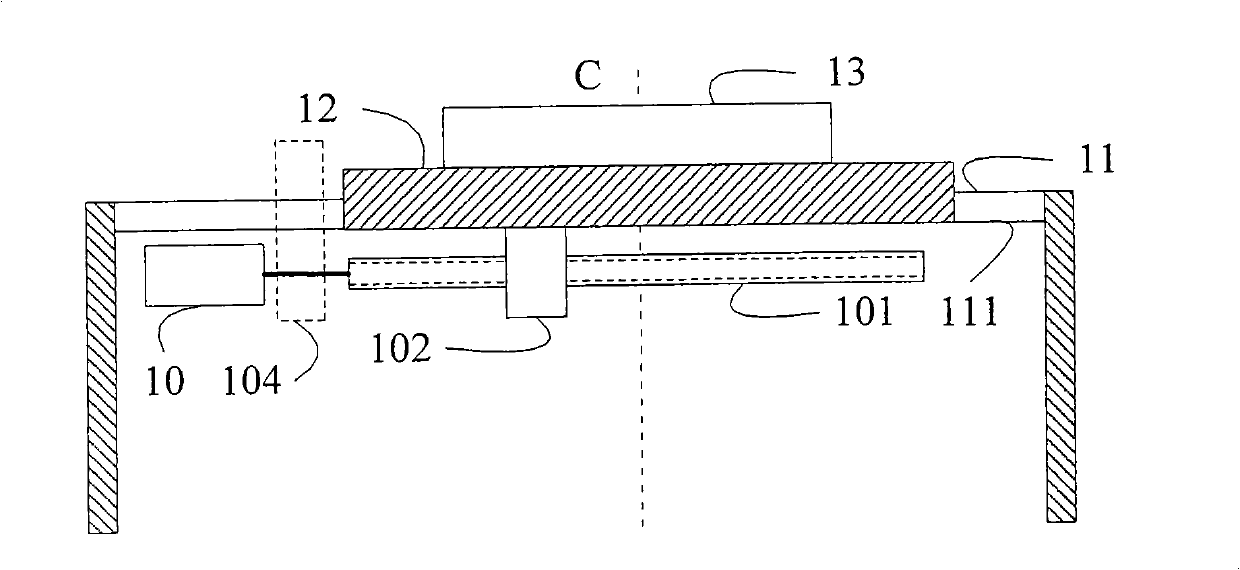

[0047] In the embodiment of the present invention, the various mechanical transmission structures between the motor that drives the sliding seat of the working table and the working table are removed, and two motors are used to drive the horizontal movement of the sliding seat of the working table and the reciprocating circular swing of the working table respectively.

[0048] Among them, the two motors can be respectively connected with the slide seat of the worktable and the worktable through a simple mechanical transmission structure of single-stage transmission, or directly connected through a mechanical connection structure similar to a shaft coupling.

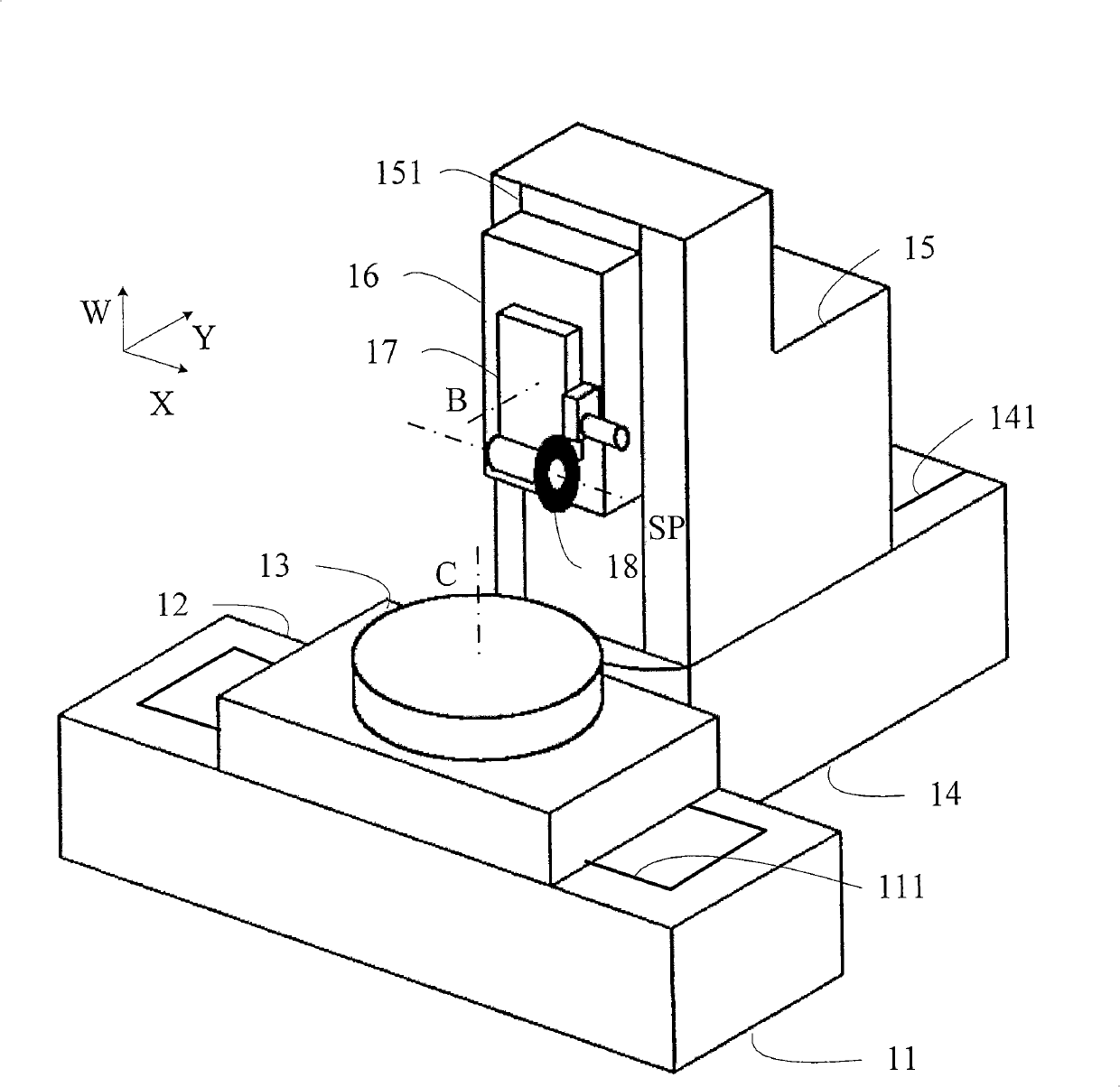

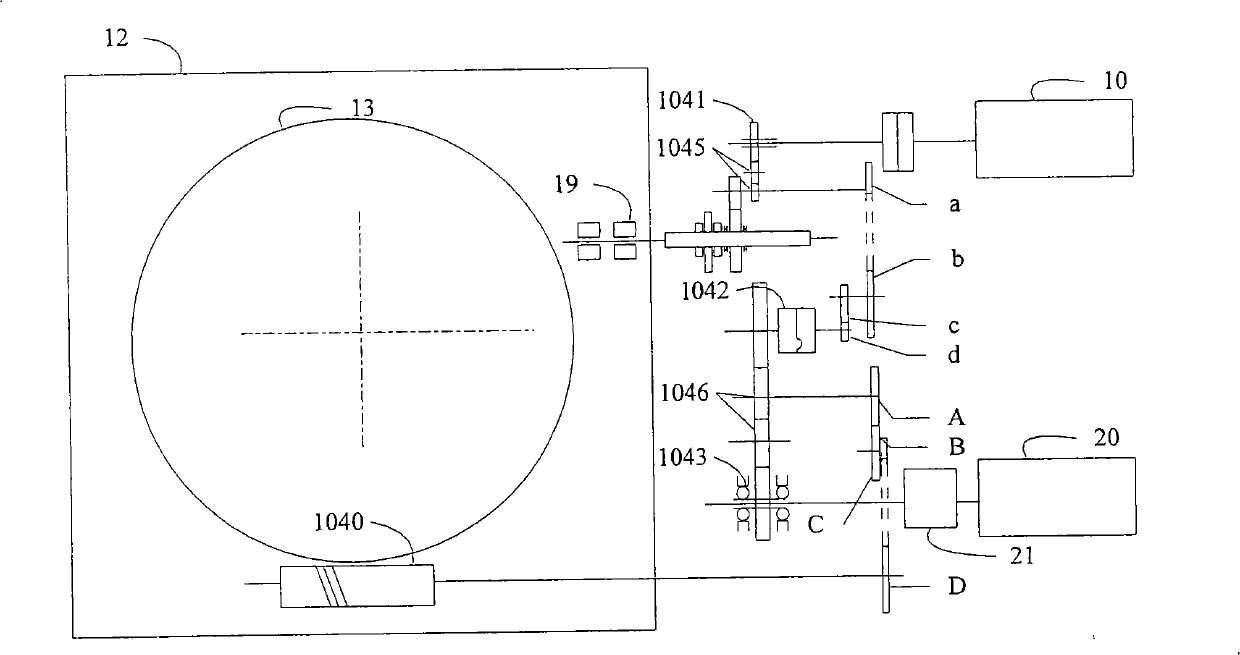

[0049] image 3 It is a schematic structural diagram of a digitally controlled generating gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com