Injection molding machine

A technology of injection molding machines and machines, applied in the field of injection molding machines, can solve problems such as difficulty, environmental pollution, health hazards of staff, etc., and achieve the effects of preventing discharge to the workshop, cleaning the working environment, and avoiding hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings.

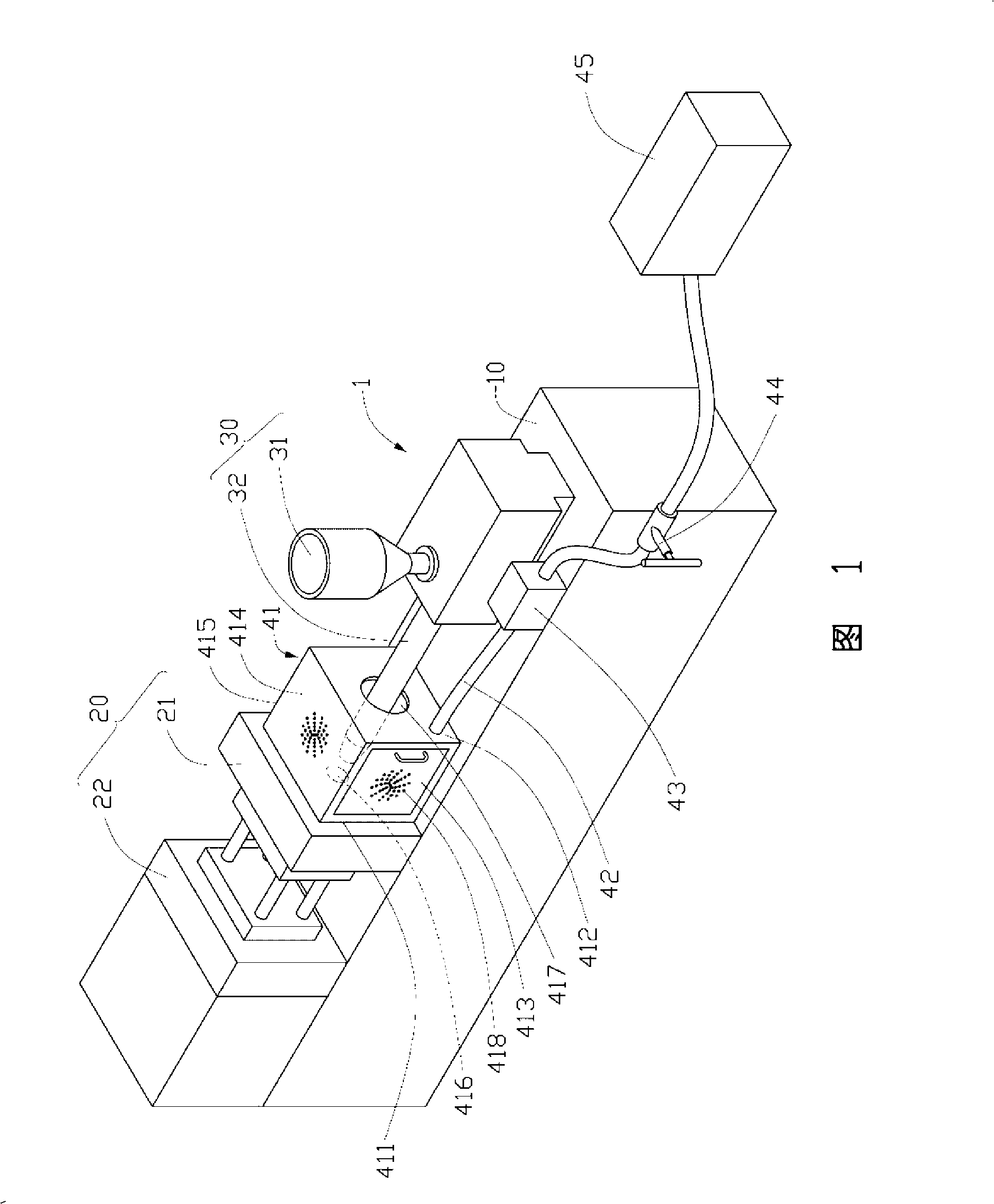

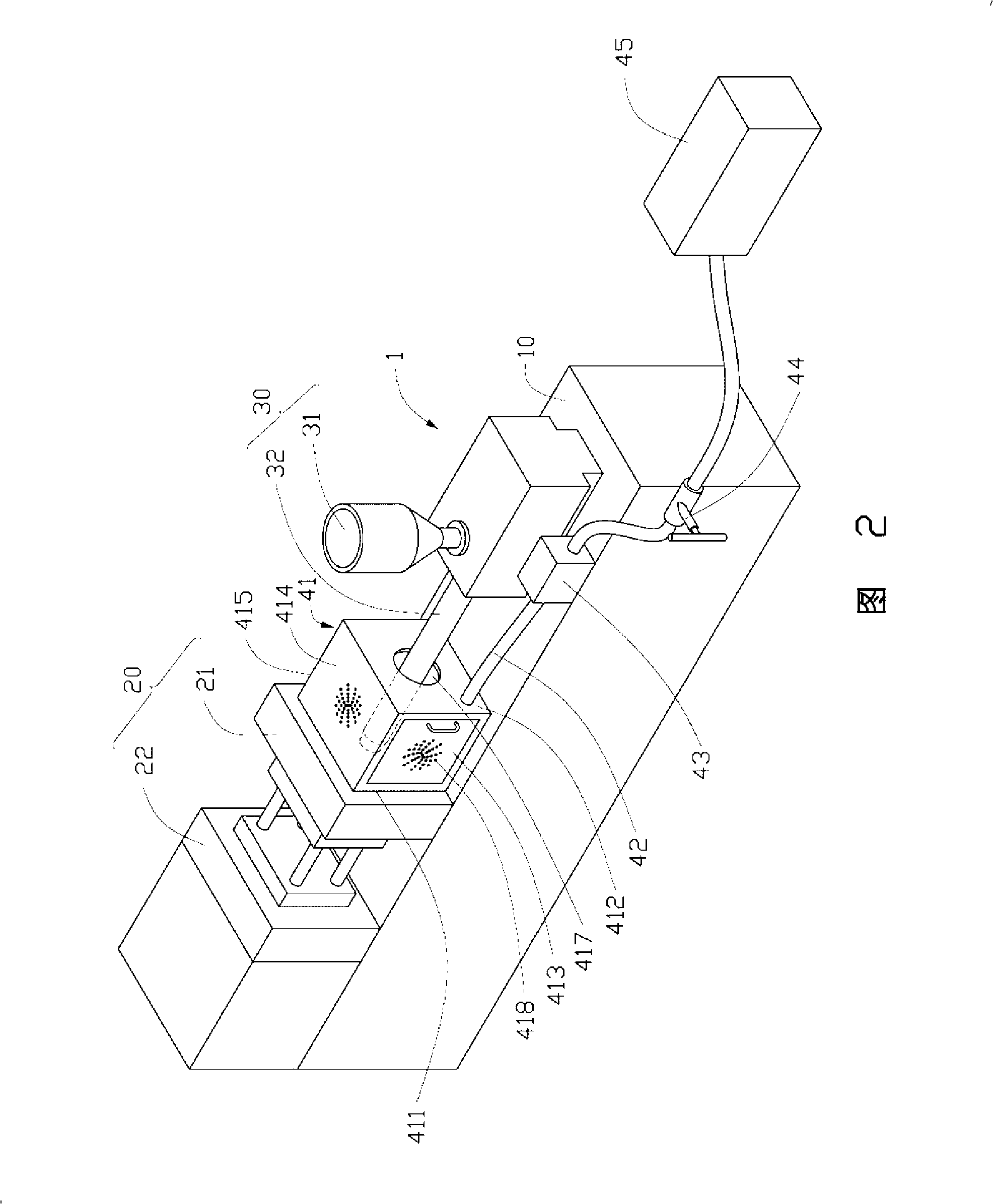

[0010] Please refer to FIG. 1 , which is a schematic diagram of the structure of the injection molding machine 1 according to the embodiment of the present invention when cleaning materials. The injection molding machine 1 includes a machine base 10 , a mold 20 disposed on the machine base 10 , and an injection device 30 disposed on the machine base 10 . The mold 20 includes a fixed template 21 and a movable template 22 , the fixed template 21 is provided with a sprue gate (not shown), and the injection device 30 includes a hopper 31 and a feed rod 32 communicated with the hopper 31 .

[0011] The injection molding machine 1 further includes a gas filtration system, which includes a hollow gas collection box 41 , an air duct 42 , a filter 43 , an air valve switch 44 and an air extraction device 45 . The hollow air collection box 41 is arranged on the machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com