Briquette roll type granulator

A granulator and roller technology, which is used in material forming presses, presses, manufacturing tools, etc., can solve the problems of waste, honeycomb-type briquette, and inability to send lump coal to the grate, etc. To achieve the effect of good air permeability and full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

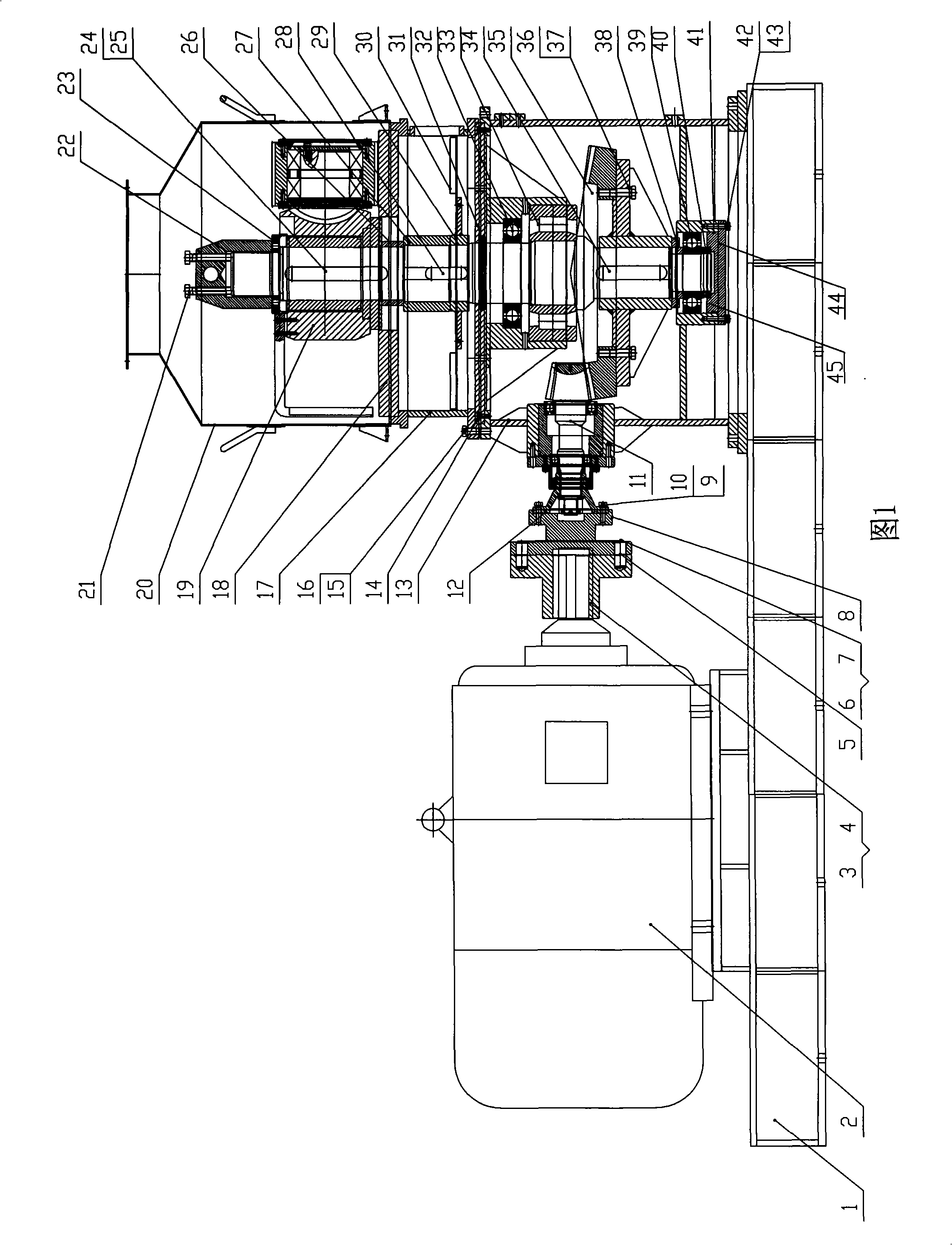

[0009] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0010] As shown in Figure 1, it includes a base 1, a motor 2, a first coupling 3, a flat key 4, a pin 5, a cover plate 6, an inner hexagonal screw 7, a second coupling 8, a spring washer 9, and a hexagonal bolt 10. Driving shaft 11, O-ring 12, lower box body 13, upper bearing seat 14, hexagonal bolt 15, spring washer 16, middle box body 17, template 18, trident pressure roller 19, upper cover 20, hexagonal bolt 21, Lock nut 22, pressing plate 23, main shaft 24, flat key 25, first bushing 26, second bushing 27, flat key 28, throwing rack 29, throwing tray 30, skeleton oil seal 31, deep groove ball bearing 32 , ball bearing 33, flat key 34, large gear 35, spring washer 36, bolt for hexagonal reaming hole 37, gasket 38, deep groove ball bearing 39, thrust ball bearing 40, O-ring 41, standard spring washer 42 , Hex bolt 43, stuffy cover 44 and lower beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com