Industrial production method for clindamycin or salts thereof

A technology of clindamycin and lincomycin, applied in the direction of sugar derivatives, organic chemistry, etc., can solve the problems of low yield, cumbersome operation, HPLC purity rarely reaches 90%, etc. The effect of easy handling and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

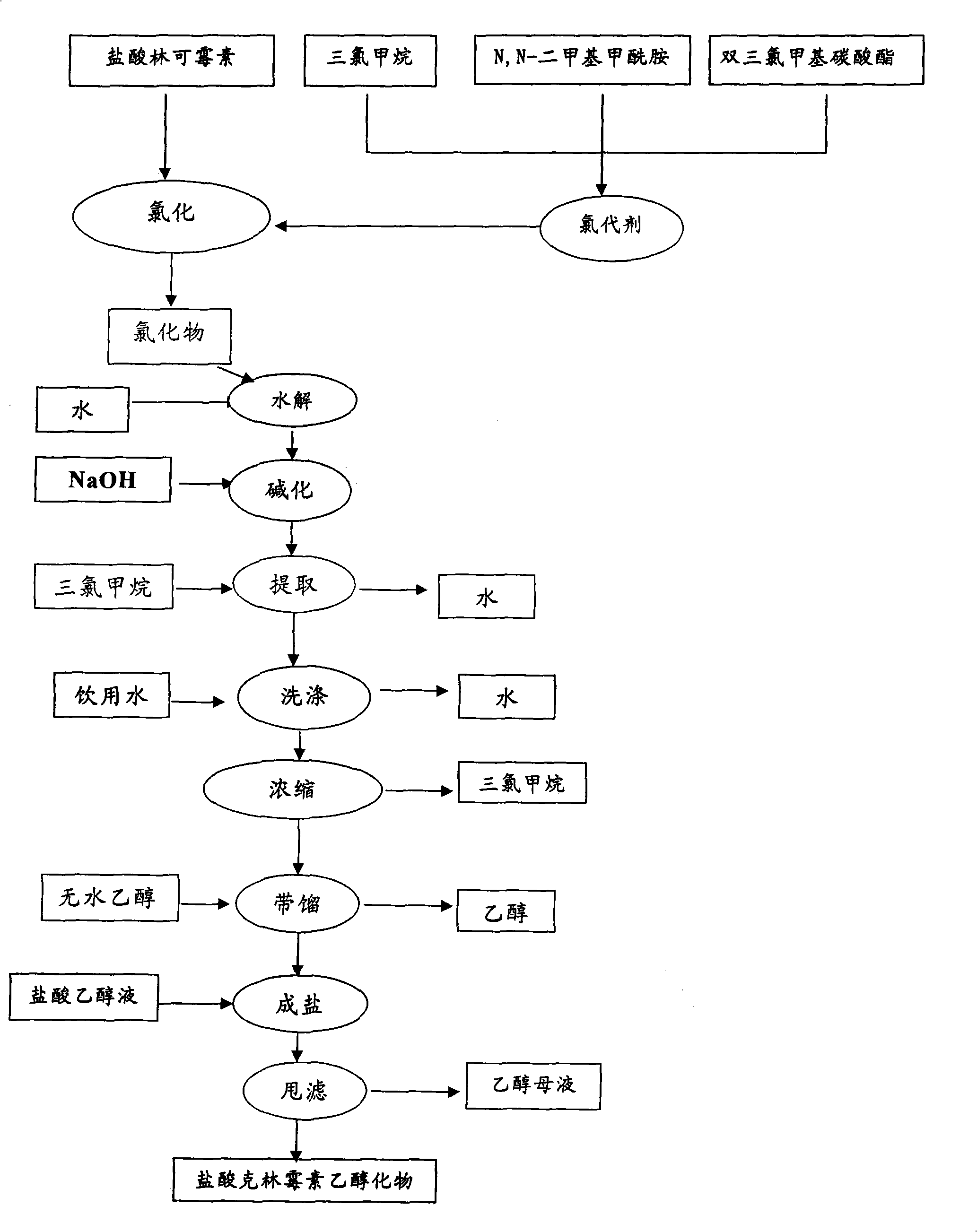

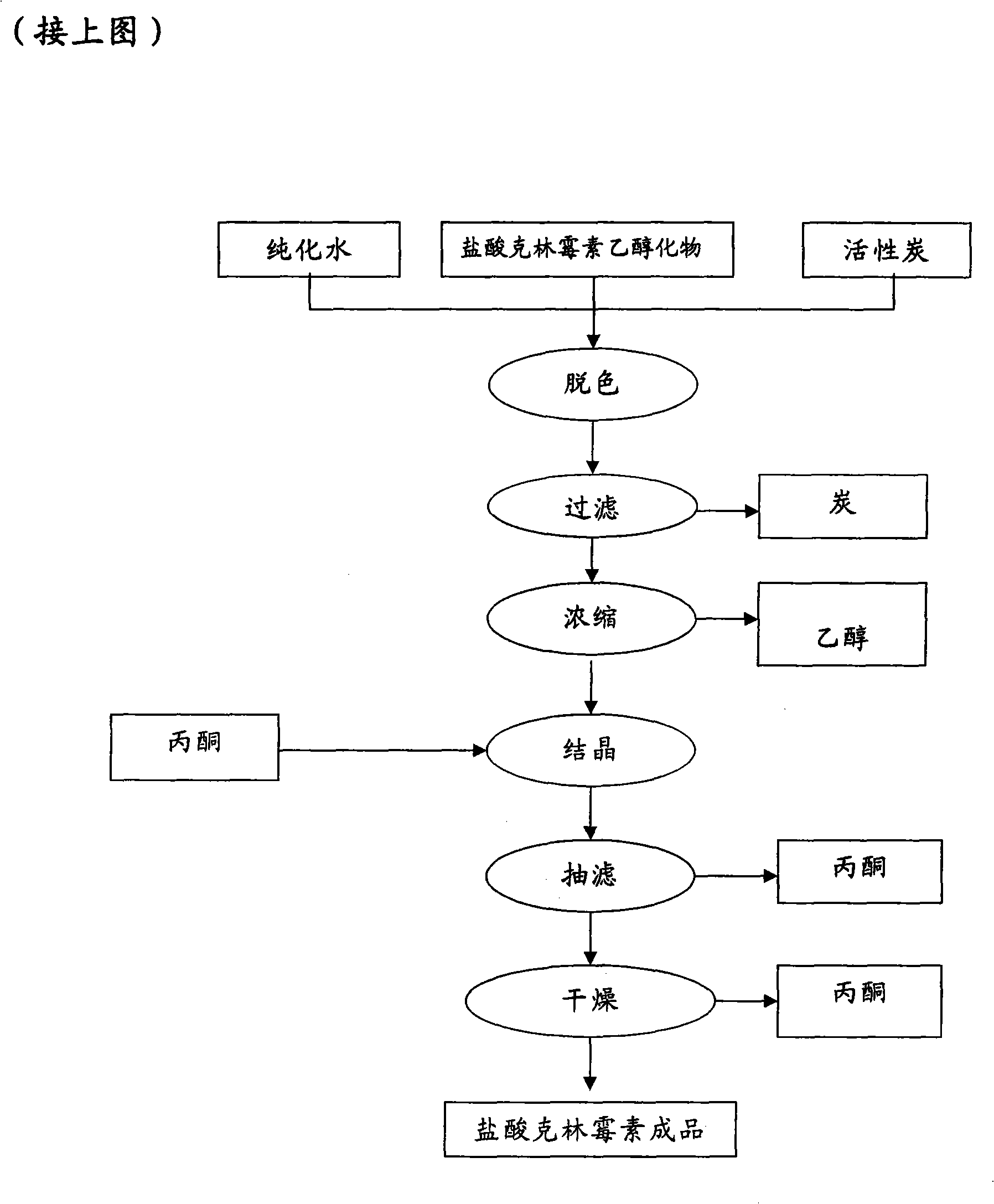

Method used

Image

Examples

Embodiment 1

[0048] 1. Chloride Preparation

[0049] 1.1 Chlorinating agent [(CH 3 ) 2 N=CHCl + ] Cl - preparation of

[0050] At 25±5°C, pump 270kg of chloroform into the reactor, add 115kg of N,N-dimethylformamide, and pump it into the high-level tank. Then add 375 kg of chloroform and 126.5 kg of bis-trichloromethyl carbonate into the main reaction pot, blow nitrogen, and when the ice brine drops to 0°C, start to add the N,N-dimethylformamide prepared above dropwise. Chloroform solution of amide, maintain the internal temperature at 10±2°C during the dropwise addition. After dropping, stir for 1 hour, heat up to an internal temperature of 15-25°C and react for 0-3 hours, cool down in ice-water solution to obtain the chlorinated agent [(CH 3 ) 2 N=CHCl + ] Cl - solution.

[0051] 1.2 Preparation of Chloride

[0052]When the internal temperature dropped below -2°C, 100 kg of lincomycin hydrochloride was added under the protection of nitrogen, and the interlayer was maintained t...

Embodiment 2

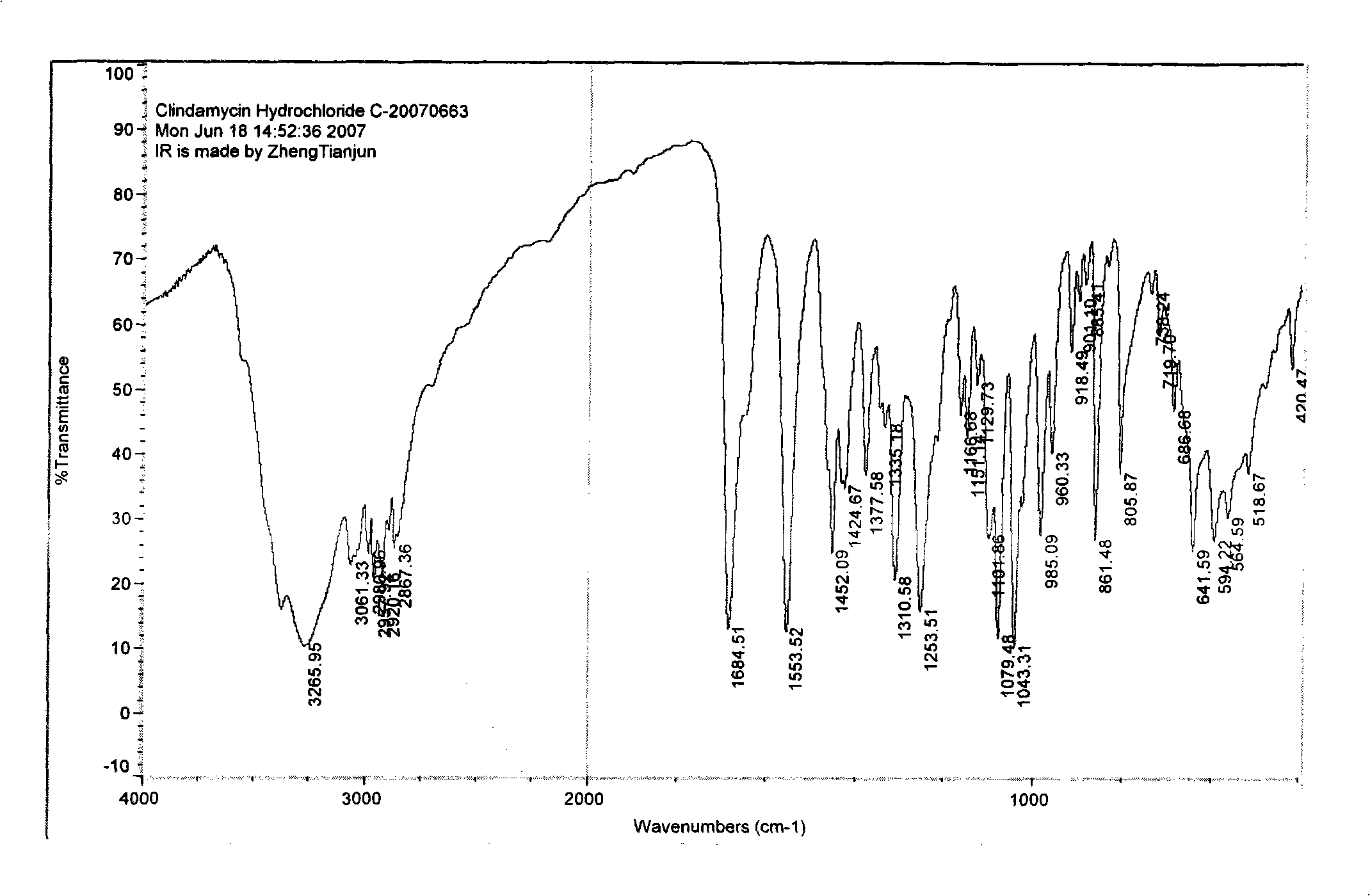

[0072] According to the method of embodiment 1, just replace 126.5kg bis-trichloromethyl carbonate with 150kg trichloromethyl chloroformate, obtain clindamycin hydrochloride, HPLC purity 97.8%, total molar yield is calculated with respect to lincomycin hydrochloride 78% to 86%.

Embodiment 3

[0074] According to the method of embodiment 1, just replace 100kg lincomycin hydrochloride with 95kg lincomycin free base, obtain clindamycin hydrochloride, HPLC purity>98%, total molar yield is calculated as to lincomycin free base 80% to 87%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com