Dash-proof distant control boring machine and its control method

A technology for remote control and drilling rigs, applied in drilling equipment and methods, automatic drilling control systems, drilling equipment, etc., can solve problems such as the inability to guarantee the safety of construction personnel, improve coal mine safety conditions, reduce casualties, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

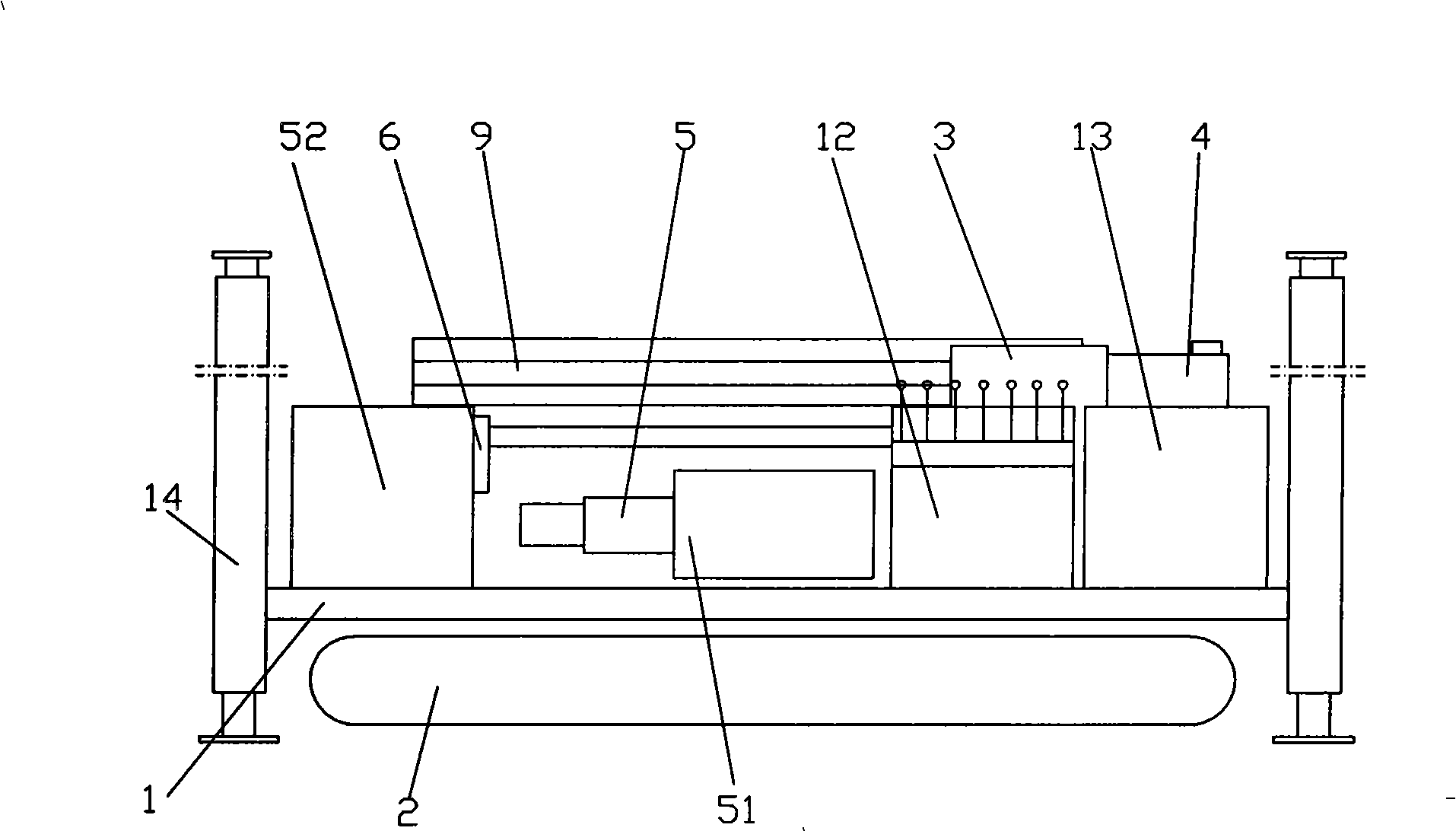

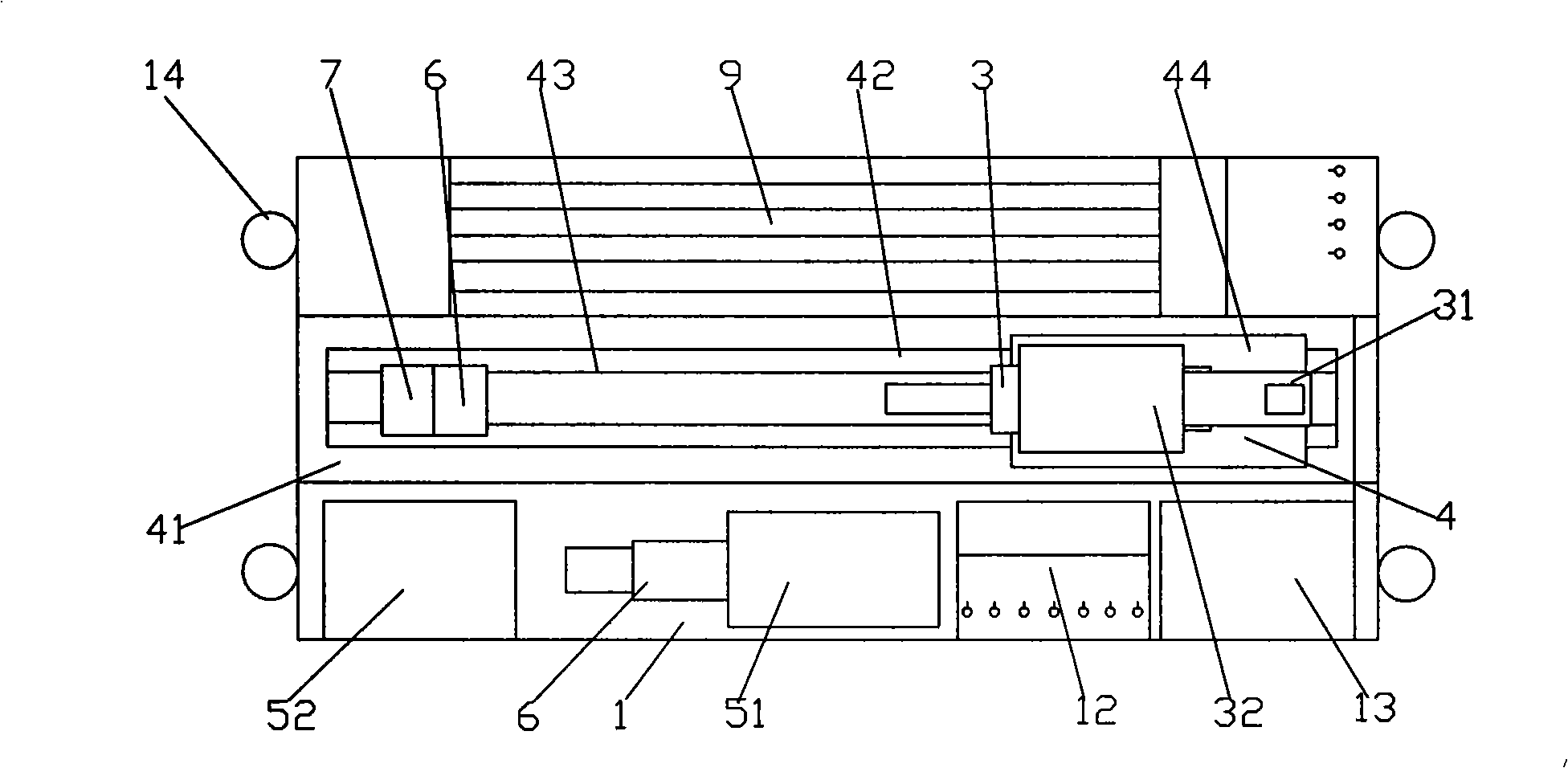

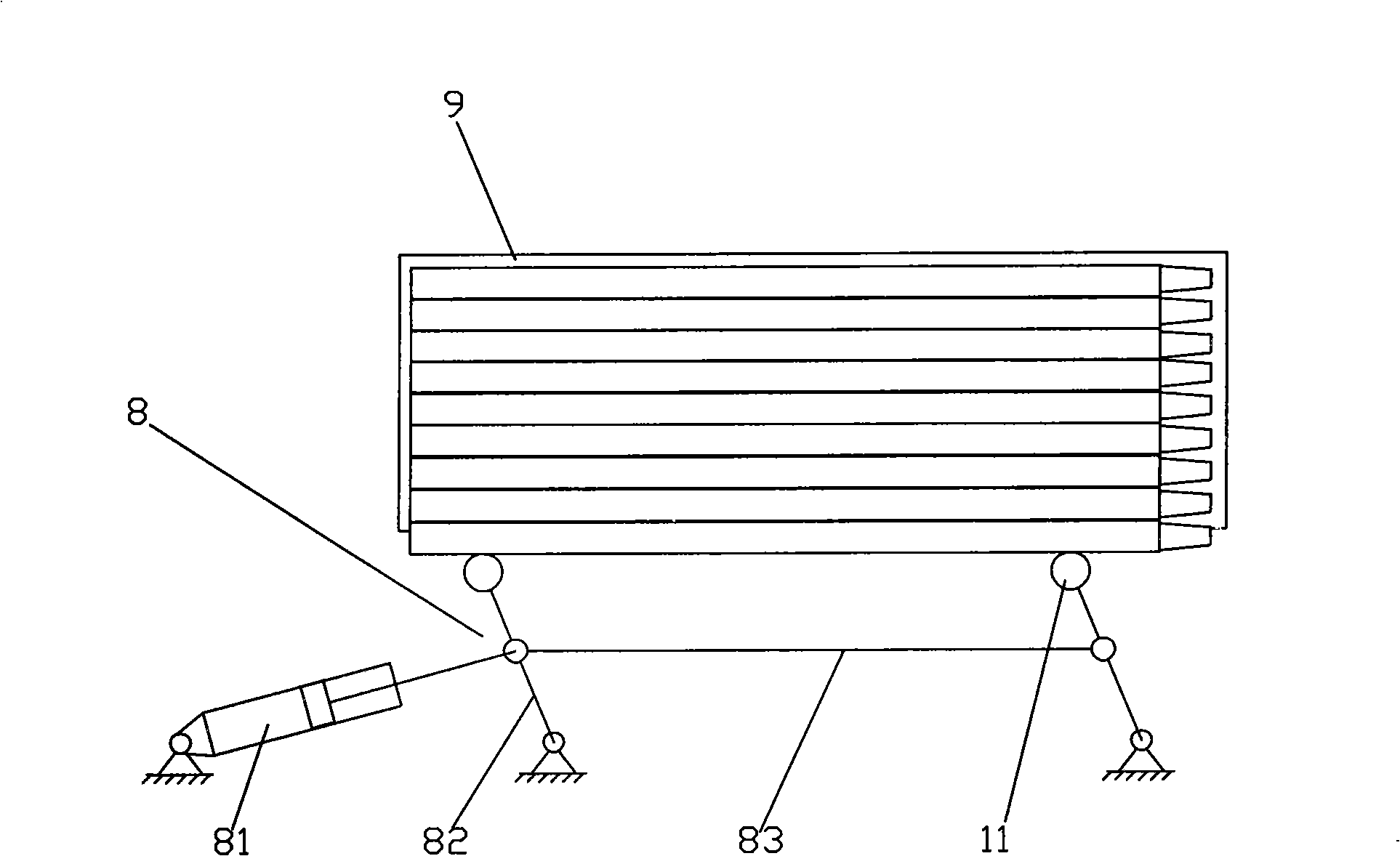

[0039] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a top view of the present invention, image 3 A schematic diagram of the drill pipe lifting mechanism, Figure 4 It is a schematic diagram of the drill pipe grabbing mechanism, as shown in the figure: the anti-outburst remote control drilling rig of this embodiment includes a base 1, a drilling rig host and a control system, the drilling rig host is arranged on the base 1, and the base 1 is set There are crawler-type traveling devices 2 and uprights 14, and the uprights 14 are controlled by a hydraulic system to fix the base 1 after the drilling rig is in place;

[0040] The main engine of the drilling rig includes a power head 3, a propulsion mechanism 4, and a power unit 5; the power unit 5 is a hydraulic power unit, including a hydraulic pump 51, an oil tank 52, and a hydraulic control multi-way valve. The group is connected with the automatic control system II, and the pilot s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com