Microminiature turbine jet rotor swirling control method

A turbojet and engine technology, which is applied in the direction of engine components, engine lubrication, turbine/propulsion device lubrication, etc., can solve the problem of payload reduction of engine performance indicators, etc., and achieve the effects of light weight, wide application range and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

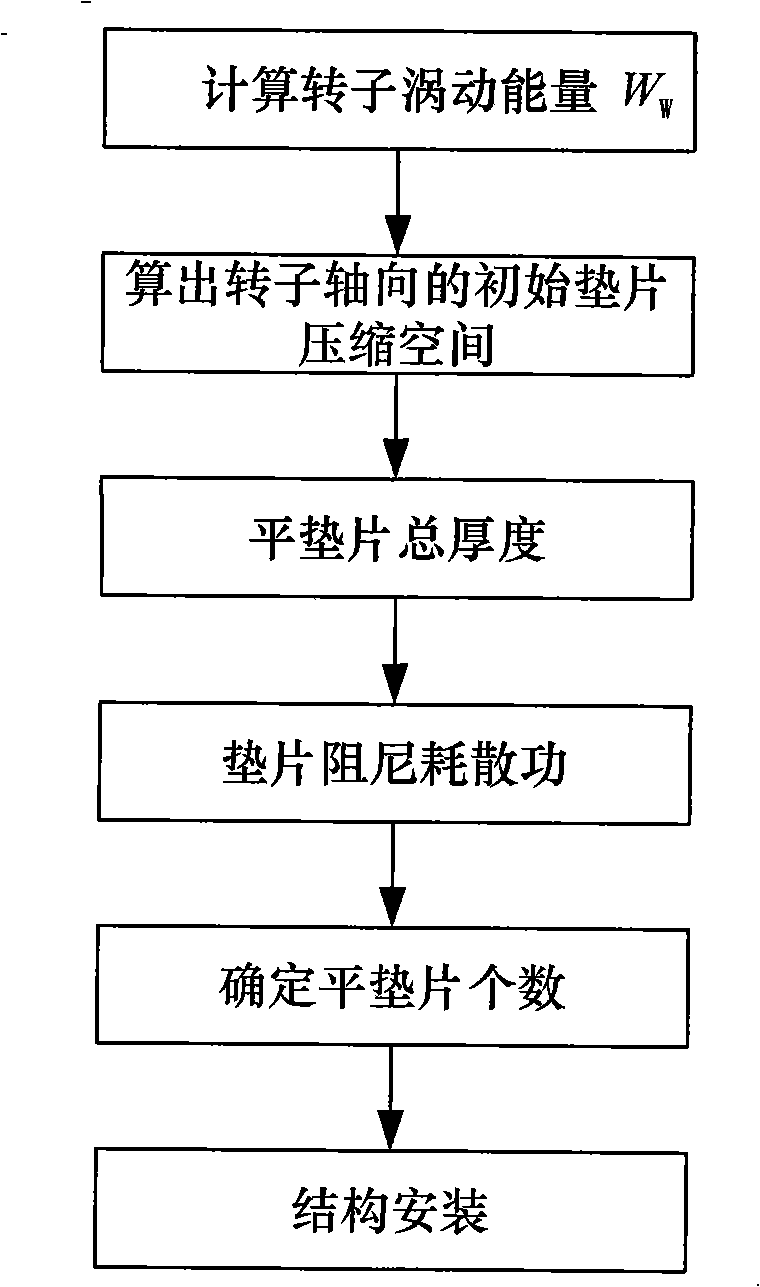

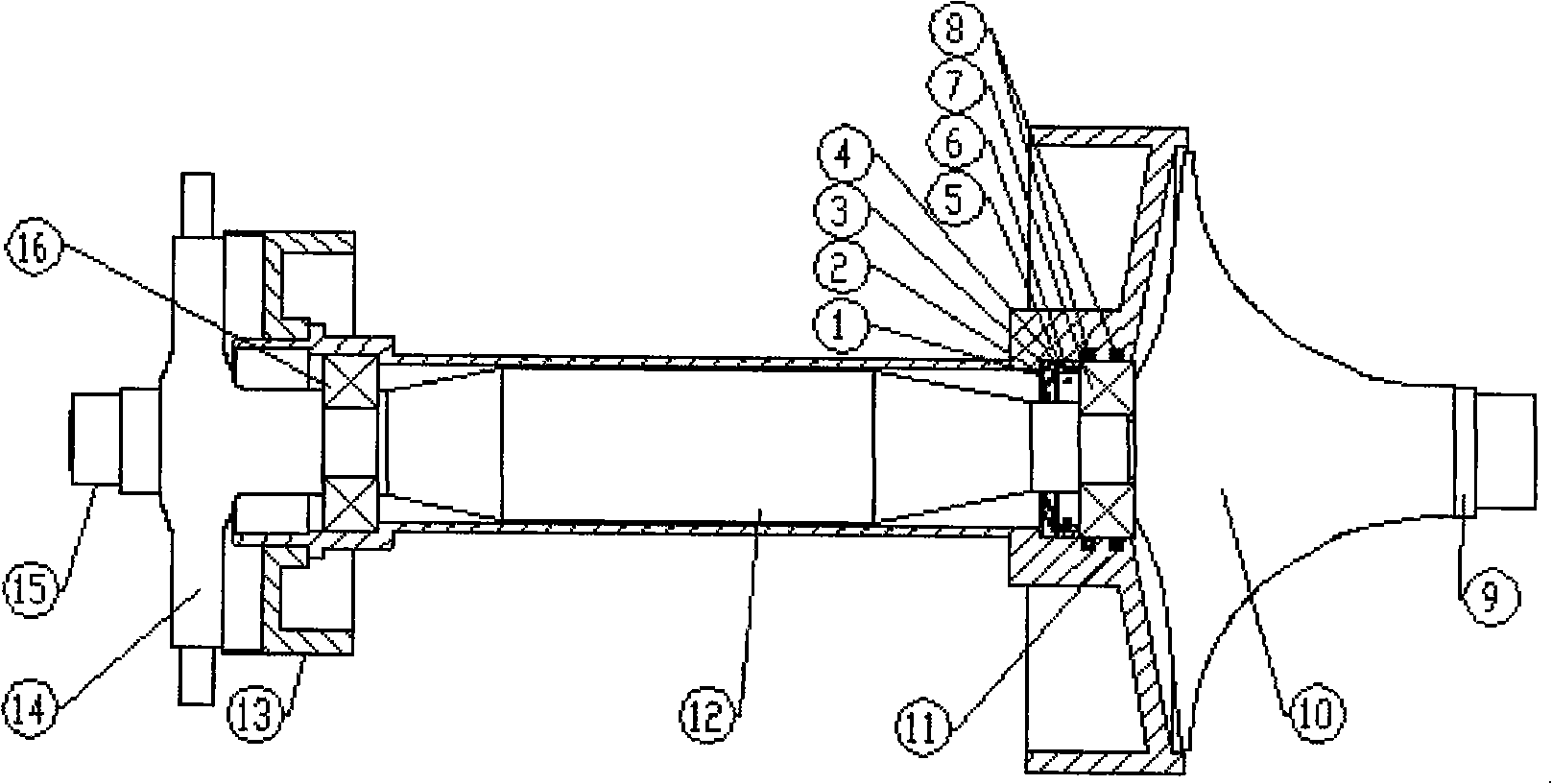

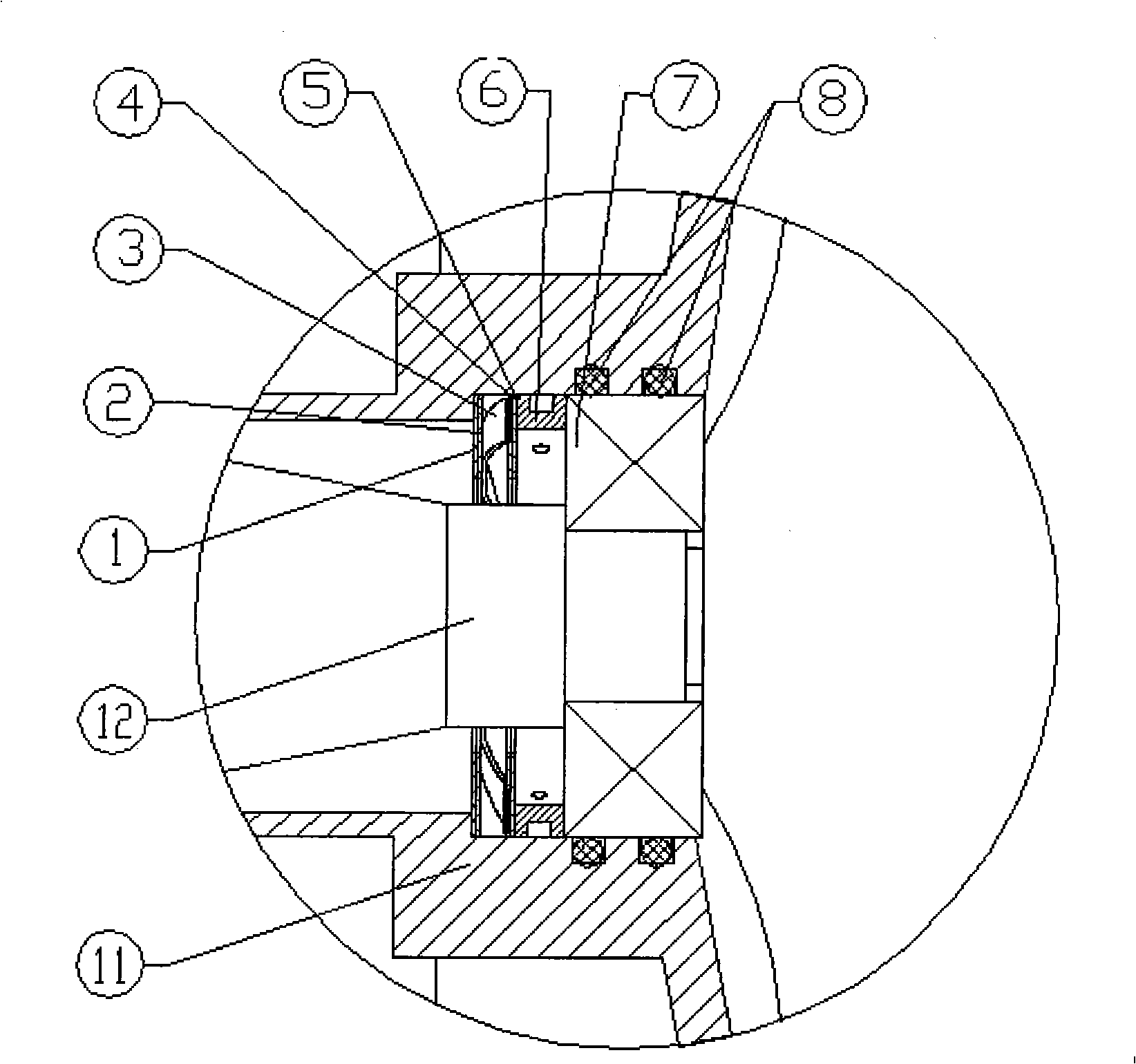

[0037] The micro turbojet engine rotor whirl control method of the present invention is illustrated below by a specific embodiment, and is carried out according to the following steps:

[0038] Step 1. Determine the number of flat gaskets by performing damping calculations.

[0039] Calculate the whirl energy W of the rotor system according to formula (1) W ,Calculated as follows:

[0040] W W = t 3 ×mR×R×(0.4×2πn / 60) 2 / 2+t 4 ×W Q (1)

[0041] Among them, n=1.2×10 5 rpm, m=1×10 -4 Kg, R=1×10 -3 m, W Q =3.5×10 -2 J,t 3 = 1, t 4 =1.

[0042] Measure the length of the corresponding two shoulders of the bearing seat sleeve 11 and the shaft 12, and calculate the initial gasket compression space in the axial direction of the rotor to be 5.34×10 -3 m, and then obtain the initial compression amount of the wave gasket according to the axial preload requirement x=1.3×10-3 m, the total thickness of the flat gasket is 9×10 -4 m, use the following formula to calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com