Caprolactam composition, method for making a sealing element, and reservoir

一种己内酰胺、聚己内酰胺的技术,应用在,紧密的封套,贮存器,贮罐领域,能够解决增加制造封套时间和成本、难以获得均匀混合物、混合物制备复杂等问题,达到机械性能改善的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] Example 1: Examples of components for the preparation of compositions according to the invention

[0128] The components used in the examples below to prepare compositions according to the invention are as follows:

[0129] -ε-caprolactam monomer (I): AP CAPROLACTAME TM , supplier: DSM FibreIntermediate B.V., melting point: 69°C;

[0130] -ε-caprolactam activator (II): AKTIVATOR O TM , supplier: Brüggemann Chemical, form: liquid, melting point: -13°C;

[0131] -ε-caprolactam Catalyst (III): NYRIM 1 CATALYST TM As catalyst (III) (bromure de (hexahydro-2H-azepin-2-onato-N) magnesium, supplier: Brüggemann Chemical, form: flakes at ambient temperature, melting point 70 °C; and -ε-caprolactone Additive: NYRIM ADDITIVE As additive (IV), sold by DSM RIMNYLON VOF, form: liquid at ambient temperature, boiling point at 760 mm Hg about 260°C, melting point below 0°C.

[0132] The chemical formulas of these components (I), (II), (III) and (IV) are as follows:

[0133]

...

Embodiment 2

[0136] Embodiment 2: the example of the device that is used to carry out the method of the present invention

[0137] In order to prepare the attached Figure 16A or the premix shown in 16C, using Bronk TM Mixer, type NCU 75 / 6. The mixer consists of two chambers (compartments) made of stainless steel into which caprolactam + catalyst mixture is introduced on one side and caprolactam + activator + additive mixture on the other side. Each chamber's internal mechanical system can mix its two premixes and preheat them.

[0138] The individual chambers of the mixer are equipped with a system that makes it possible to inject dry nitrogen into the chambers to degas the components used and keep them under a dry and inert atmosphere.

[0139] The chambers of the mixer are also equipped with metering pistons capable of injecting quantitative amounts of each premix into the rotating mould.

[0140] The mixing or contacting between the two premixes takes place outside the mixer using a...

Embodiment 3

[0144] Embodiment 3: the preparation of envelope and the test to composition of the present invention

[0145] In % by weight, the composition used in this example was as follows: 80.6% ε-caprolactam monomer, 0.4% activator, 4% catalyst and 15% additive. In this example, the total amount of composition used to form the envelope was 397 g. The resulting envelope had a volume of 3L.

[0146] Immediately after weighing the components, the ε-caprolactam monomer and ε-caprolactam catalyst were purged with dry nitrogen.

[0147] Preheat the components, mix together, and then Figure 16B Quick introduction into the rotary mold shown. The rotary mold is heated in an oven to a temperature of 160 to 190°C.

[0148] The mold rotates at a spindle speed of 9 rpm and a counter spindle speed of 6 rpm. The ratio of speed (primary / secondary ratio) is equal to 1.5.

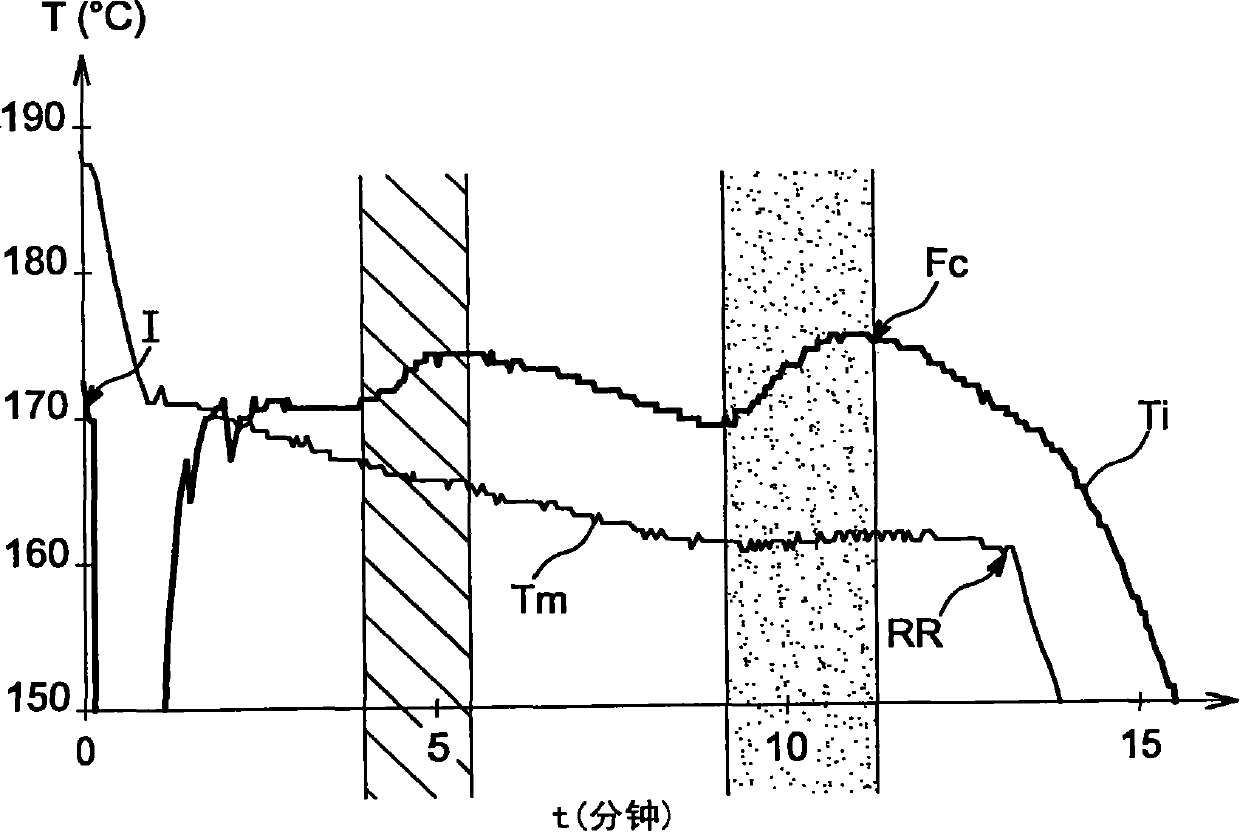

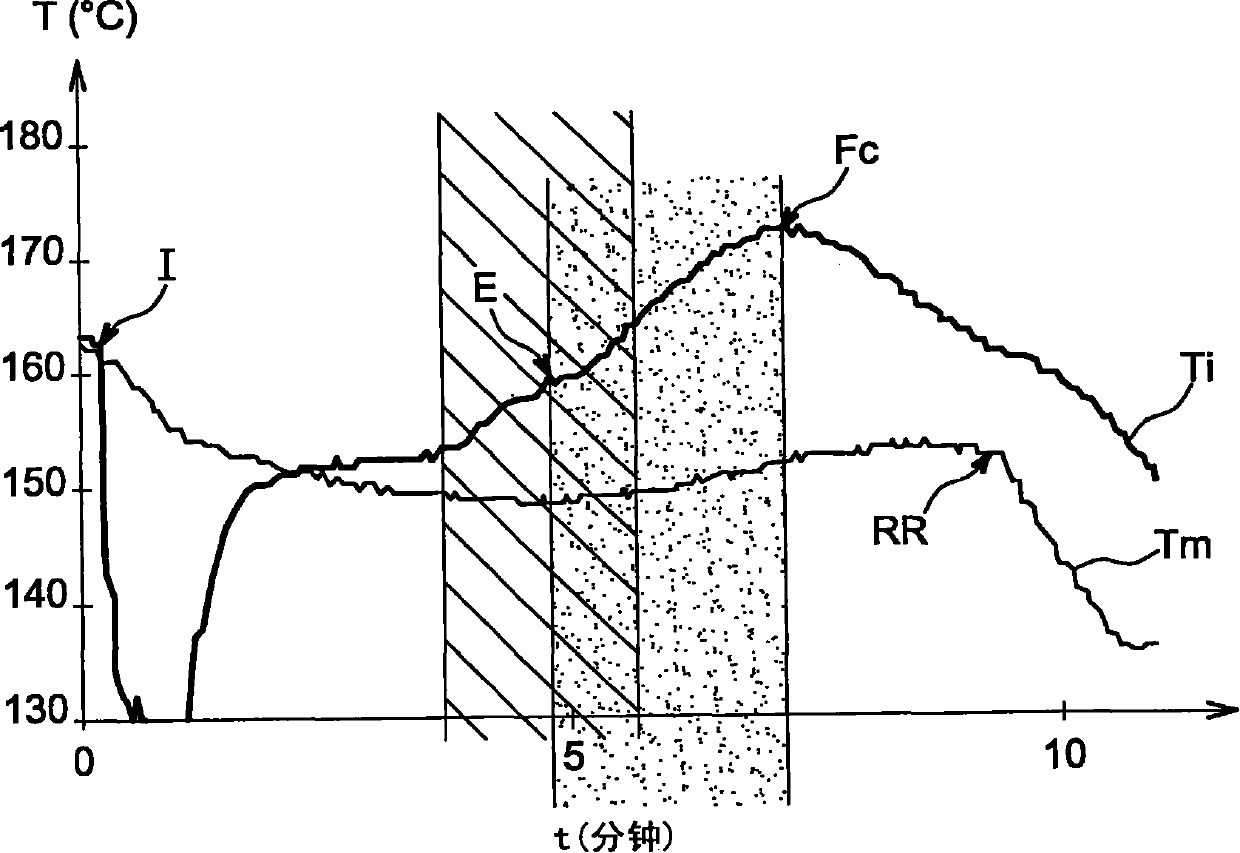

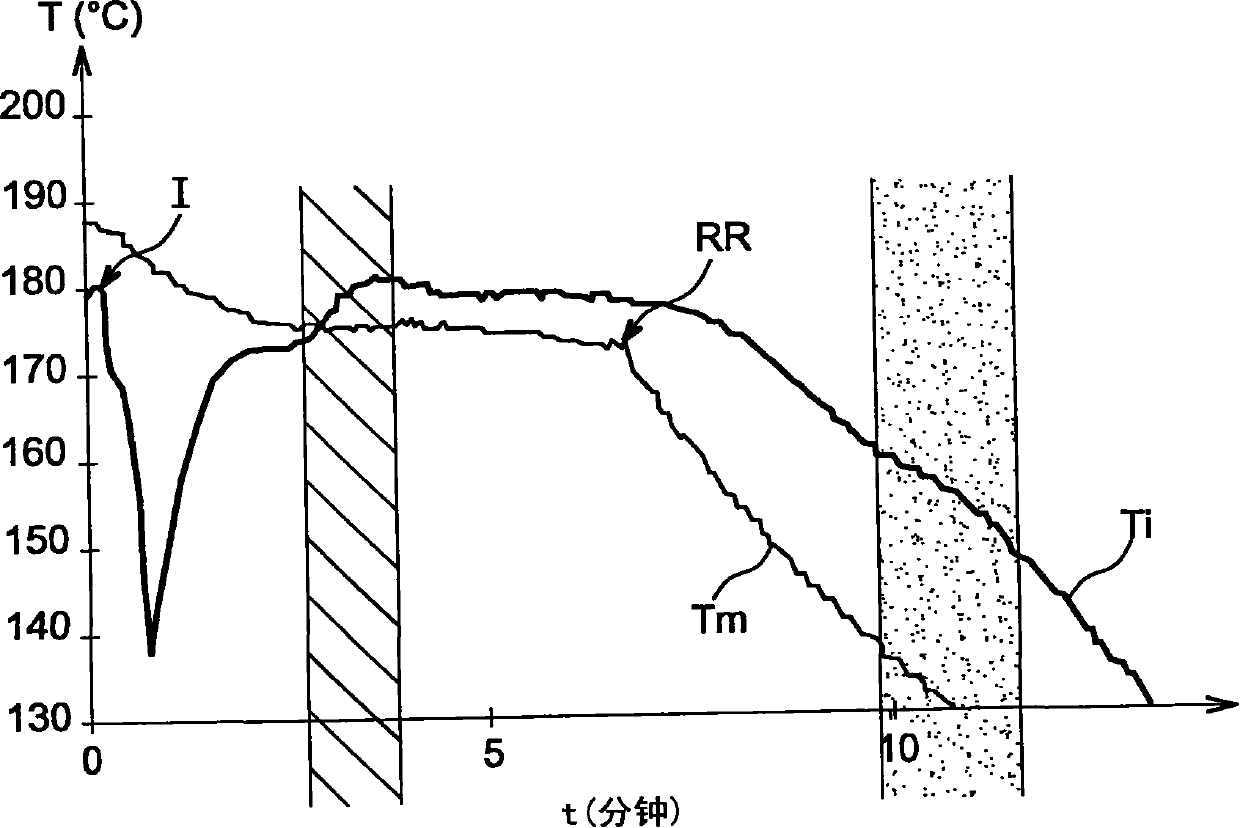

[0149] attached Figures 1 to 3 Measurements at various temperatures performed in this example are compared. In these fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com