Method for processing spheroid abnormal hole and surface using general-purpose machine and standard frock

A technology of general-purpose machine tools and standard workers, which is applied in the field of sphere hole processing, can solve the problems of inability to use general-purpose machine tools for conventional processing, low processing efficiency, and high processing costs, and achieve the effects of ensuring processing quality, improving work efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

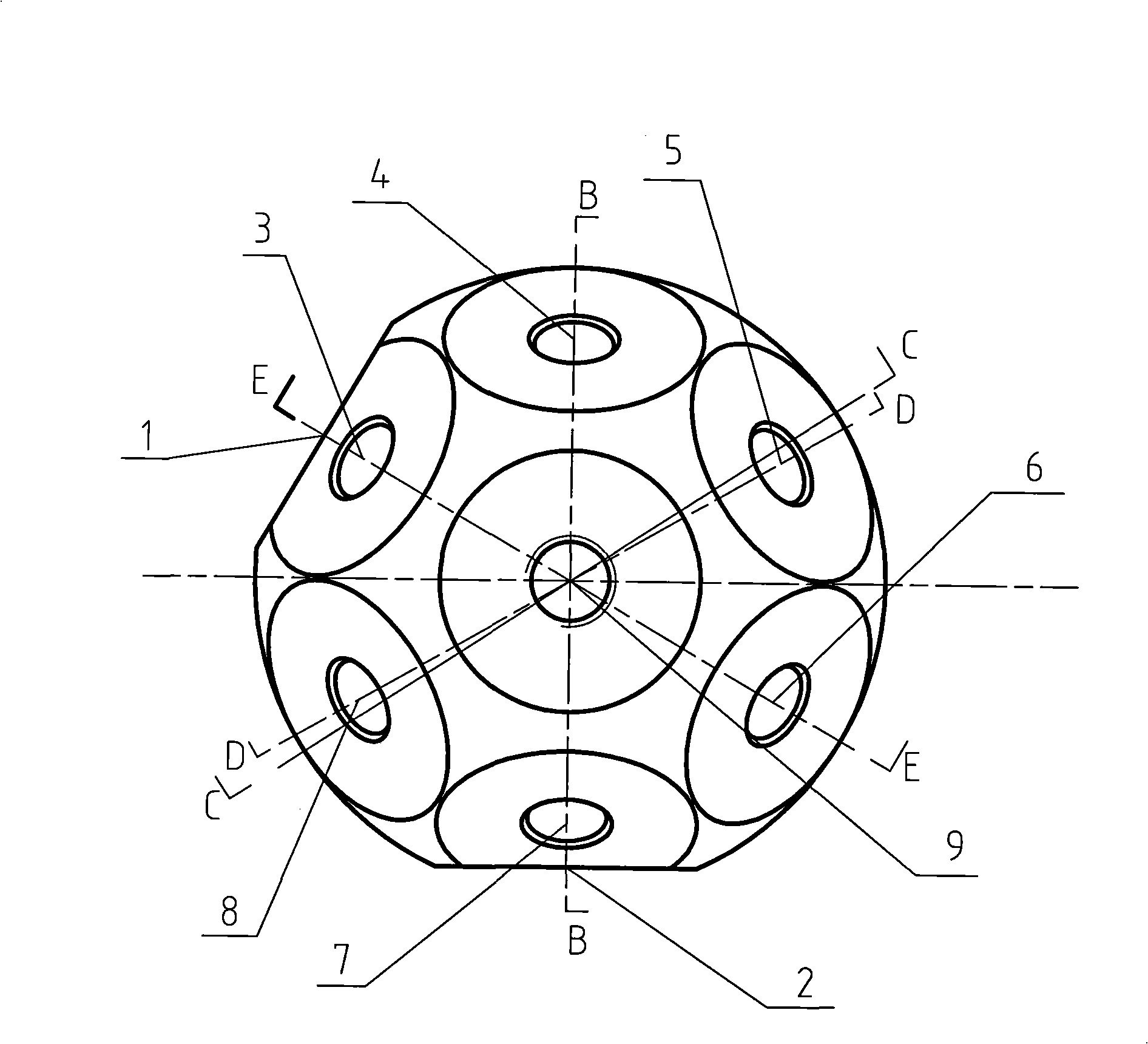

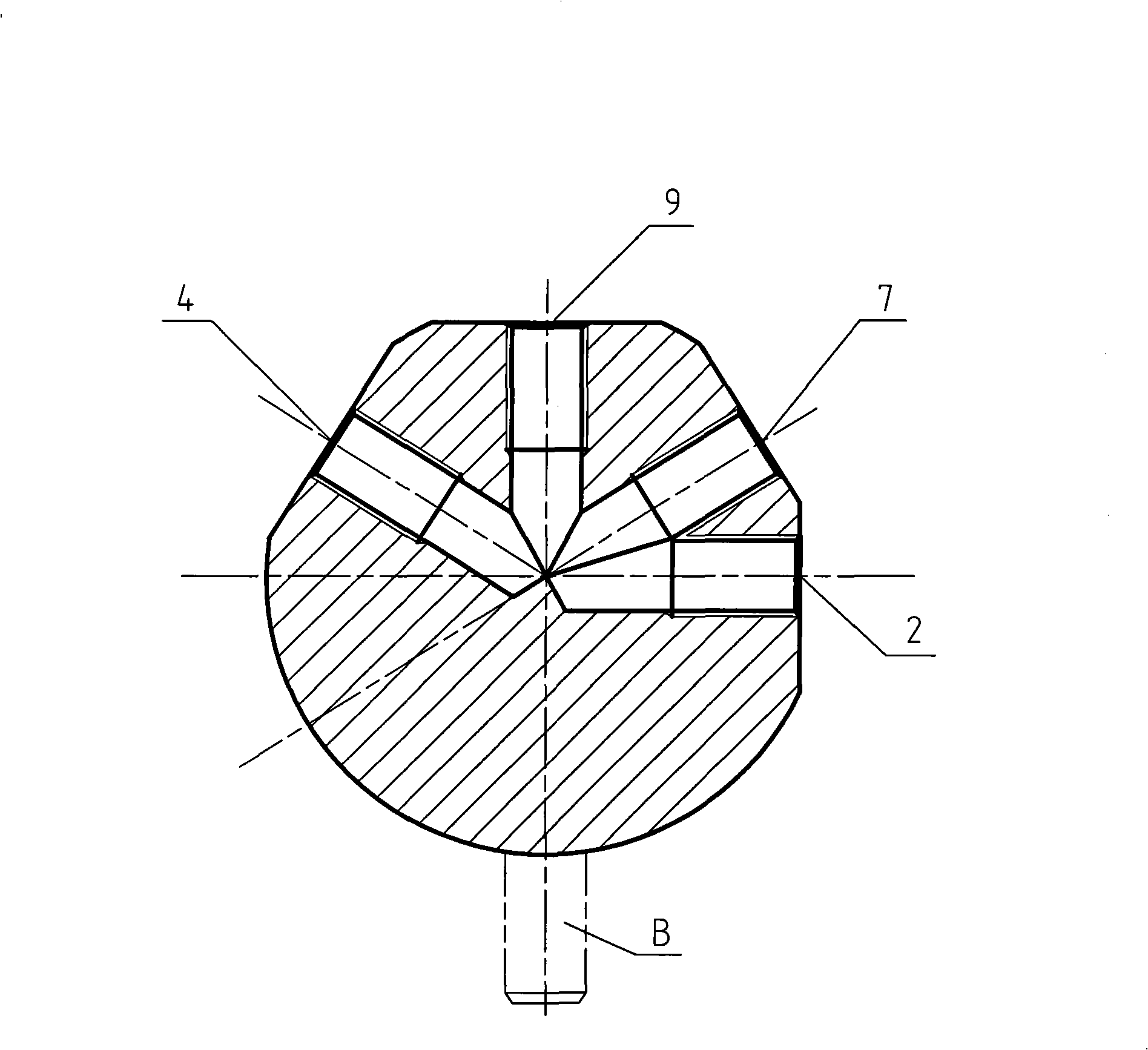

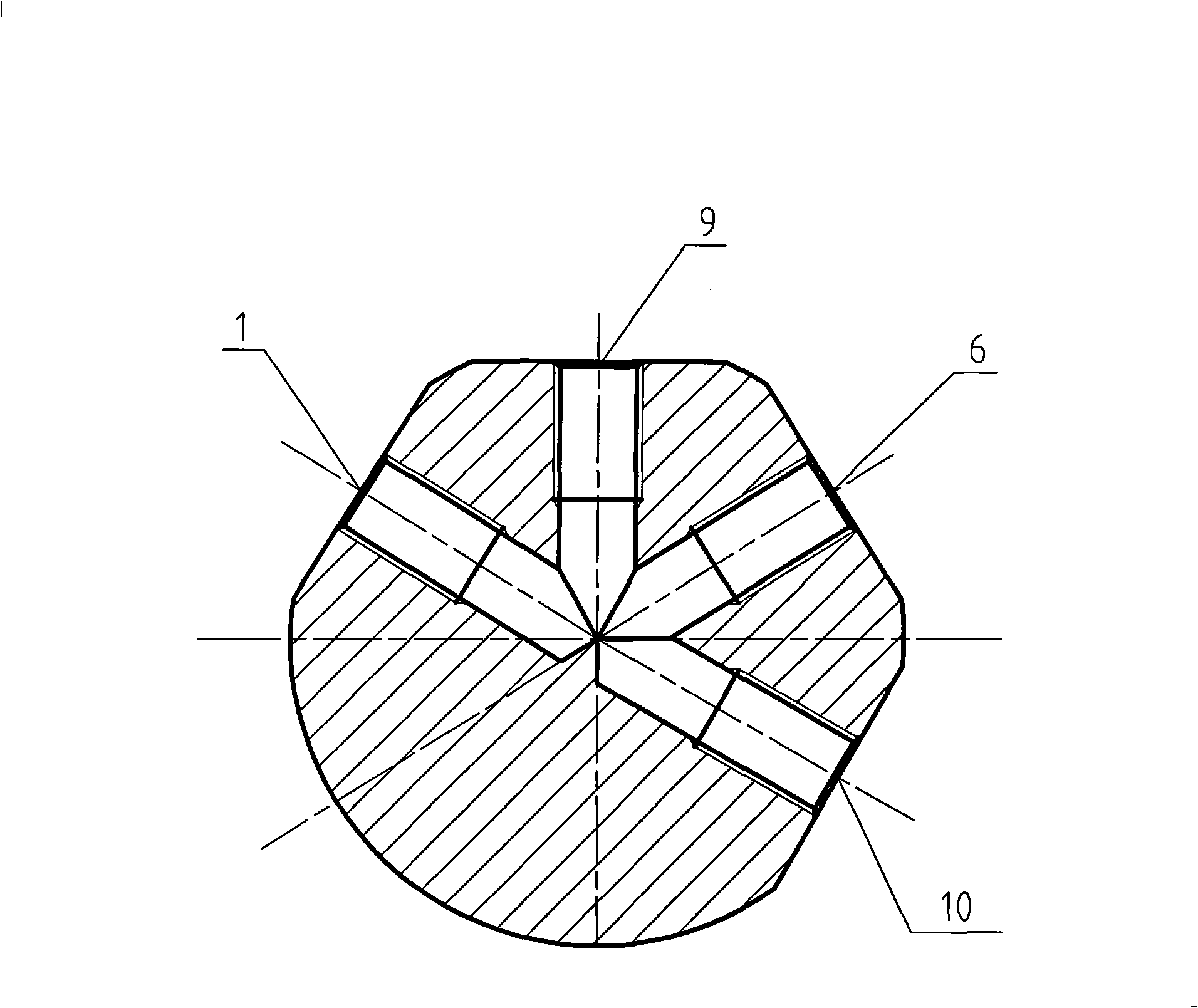

[0025] This embodiment selects a representative sphere to illustrate, according to the appended Figure 1~5 The distribution of the screw holes and planes on the 11 surfaces of the sphere shown is based on completing as many hole surface processing as possible in one clamping, reducing the cumulative error caused by the conversion of space angles, and taking into account that the center of rotation of the process intersects each screw hole on one side On the principle that the angle between each other is greater than or equal to 90°, the collet gear B is selected as the process rotation center, such as figure 2 shown.

[0026] The processing steps are as follows:

[0027] (1) Round bar blanking: put 5-6mm allowance according to the diameter of the ball, and 10mm allowance for the length.

[0028] (2) Rough turning of the sphere, keep the chuck gear B: clamp the lowered round bar on the jaws of the machine tool, drill the center hole at one end, and press the tailstock again...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com