Whole-course full-automatic quick production line of wall board

A production line and fully automatic technology, applied in ceramic molding workshops, ceramic molding machines, molds, etc., can solve problems such as distortion and deformation, and achieve the effects of small turning radius, smooth steering, and high site utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

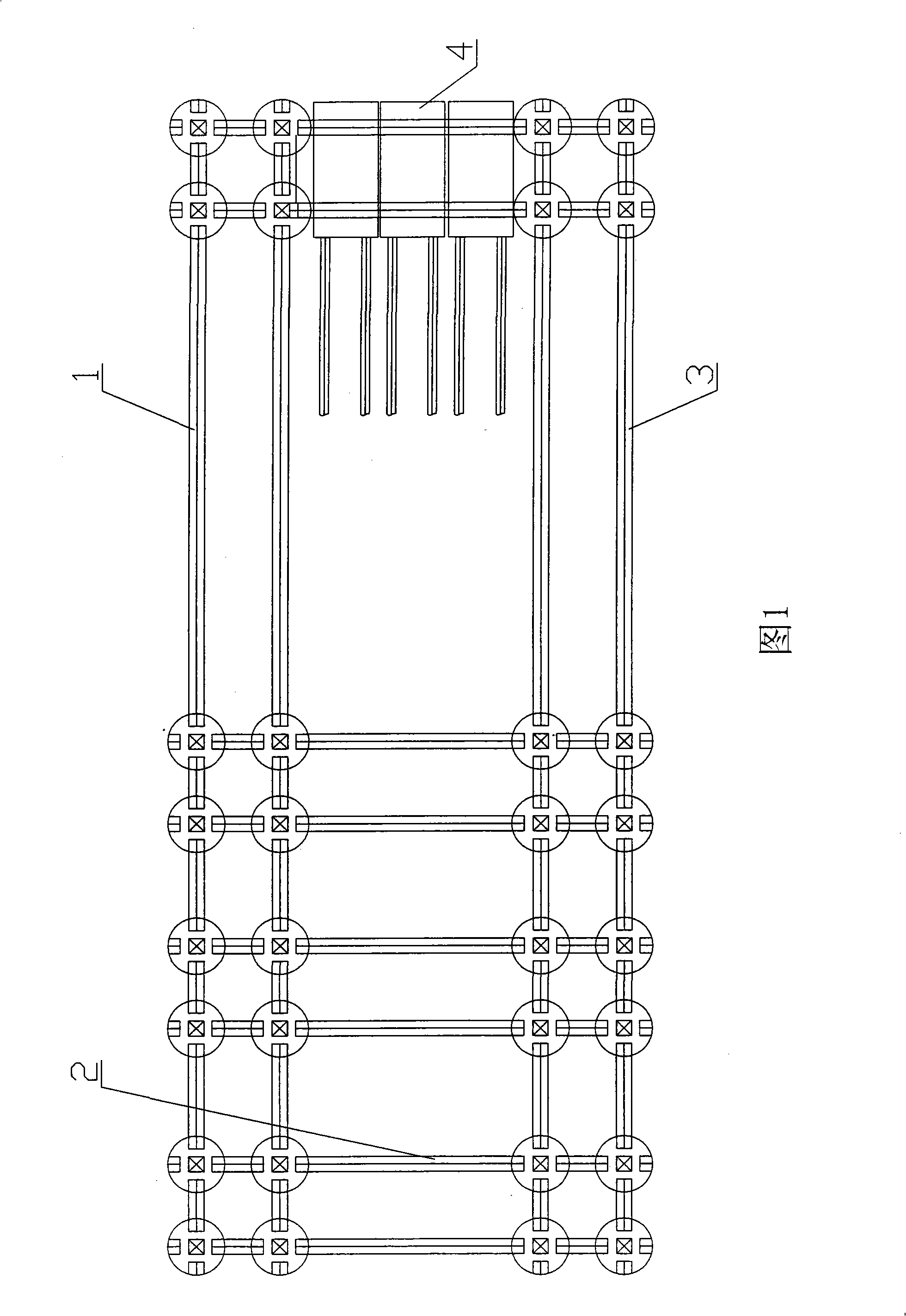

[0019] Referring to Figure 1, the full-automatic rapid production line for wall panels includes a bottom mold, a production area 1 with double-row longitudinal tracks, a transportation line 3, a storage waiting area 2 and a demoulding area 4 with double-row transverse tracks, The production area 1, the storage waiting area 2, the transport assembly line 3, and the demoulding area 4 are connected end to end in sequence to form a rectangular closed line body, and the bottom mold can move on the longitudinal track and the transverse track. The bottom mold moves smoothly on the guide rail during the whole production, waiting and demoulding process, and does not break away from the guide rail at the turning point, thus avoiding the distortion and deformation of the mold, improving the flatness of the wall panel, and avoiding the unsolidified wall just formed The board is loose and deformed, which ensures the quality of the wall board.

[0020] A transmission device is provided at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com