Non-etched flat polarization-selective diffractive optical elements

A technology of diffractive optical elements and linearly polarized light, applied in polarizing elements, optical elements, diffraction gratings, etc., can solve the problems of time-consuming, complicated etching and/or molding steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

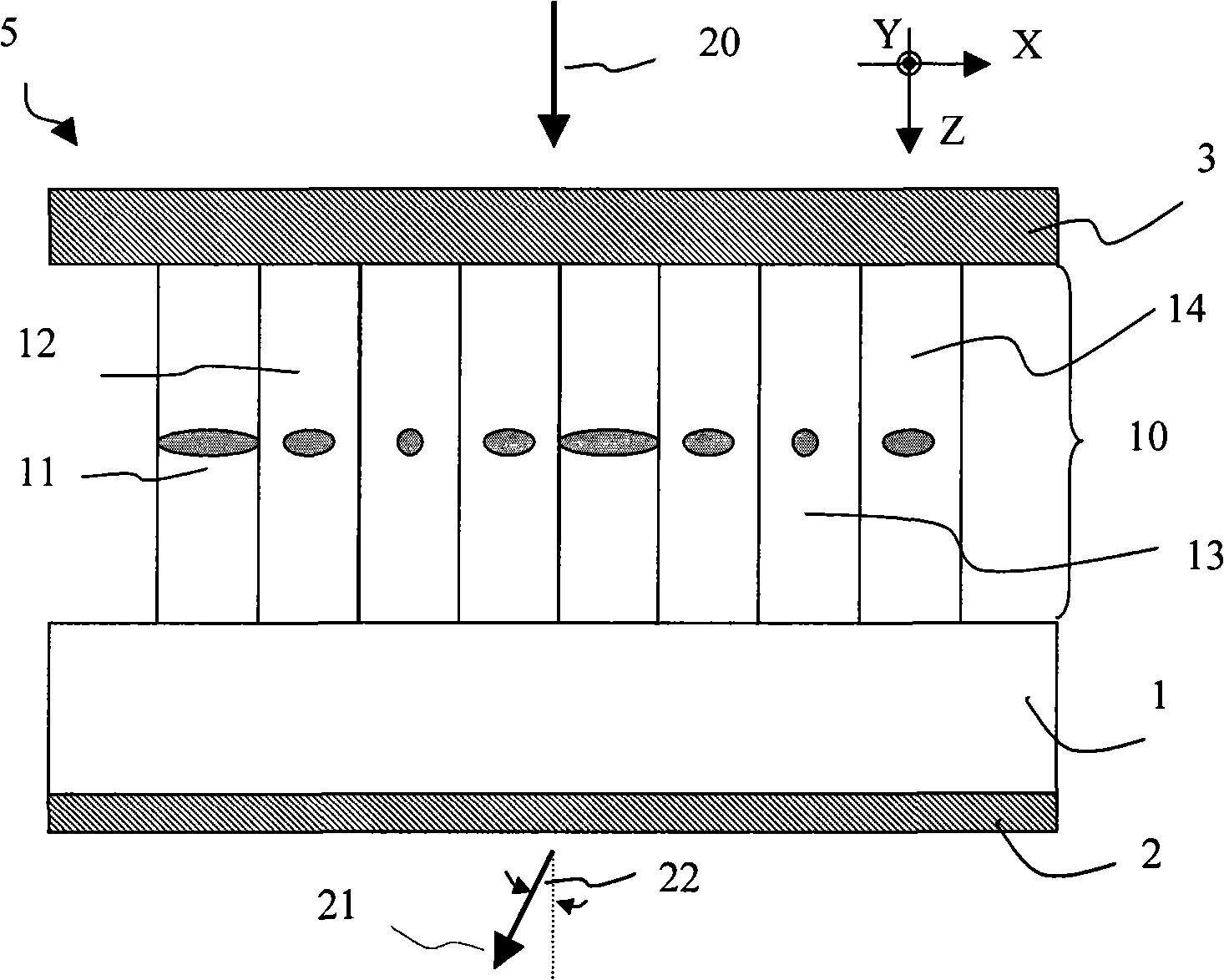

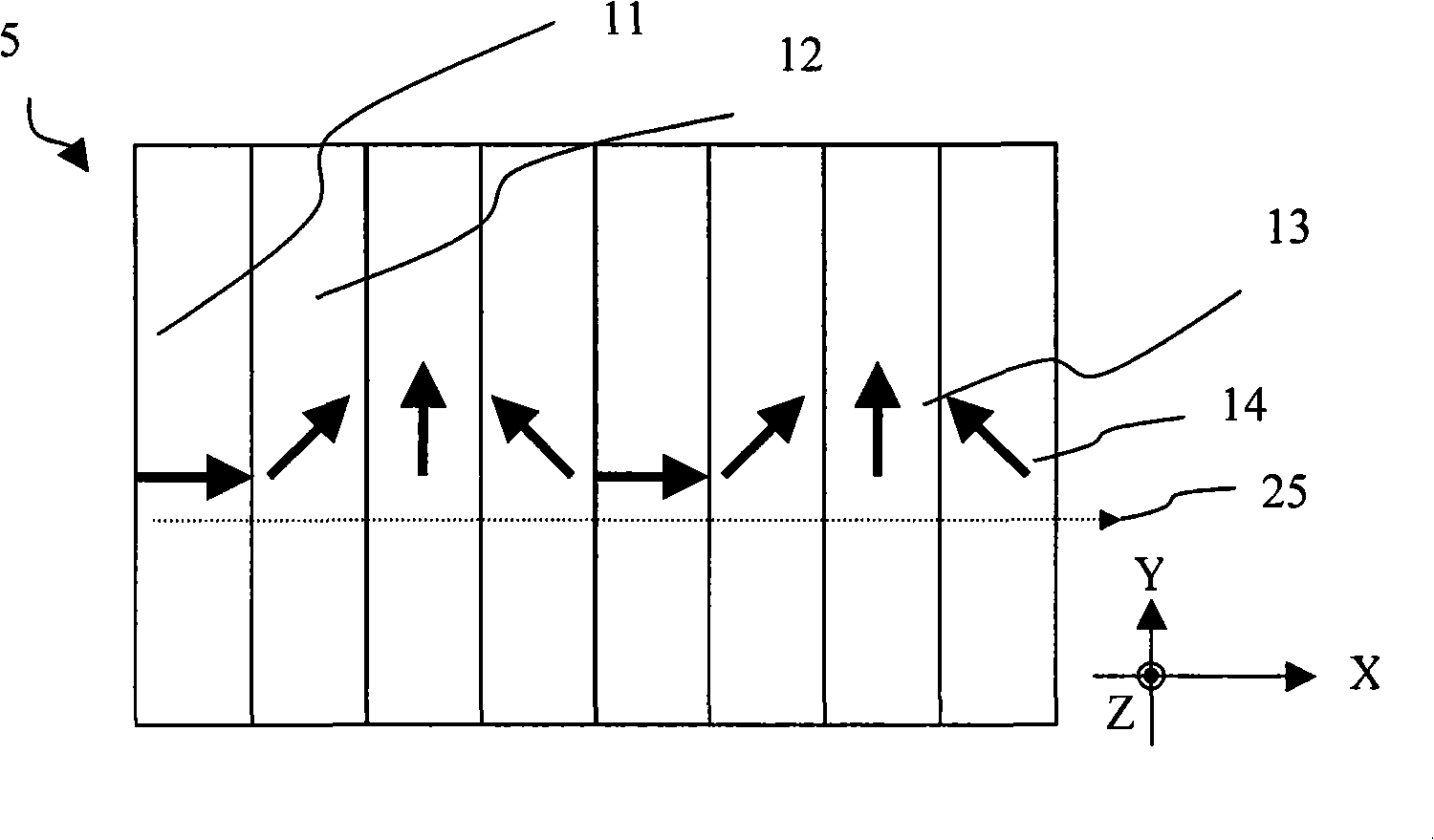

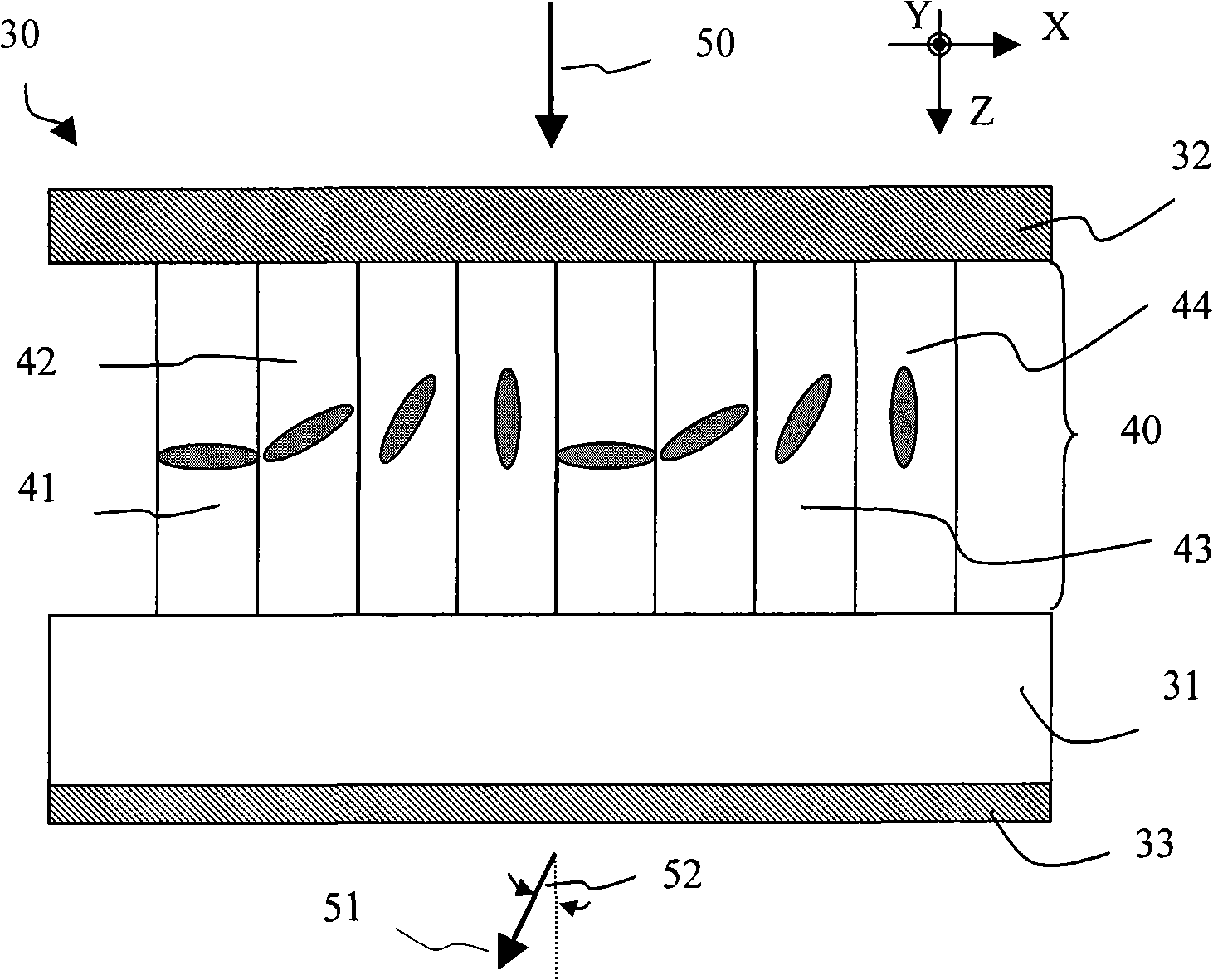

[0065] [63] A prior art thin film liquid crystal (LC) hologram structure is shown in Figure 1, which is a thickness cross-sectional view along the grating vector. The grating vectors are the planes where light is scattered by diffraction effects. The grating vector is also the pixelation direction of the 1D grating or hologram. holographic Figure 5 Comprising a substrate 1 on which is arranged a pixel array 10 with LC director orientations with variable azimuthal angles. The LC director orientations for four discrete azimuthal angles are shown in 11 , 12 , 13 and 14 . More specifically, the projection of the LC refractive index characteristic curve on the drawing plane (XZ plane) is shown. Pixel 11 has a projected director aligned parallel to the X-axis, while pixel 13 has a projected director aligned parallel to the Y-axis. The other two states, pixels 12 and 14 have projected directors contained in the XY plane, but not parallel to the X and Y axes. The hologram elemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com