Water-based one-pack-type coating composition and coated article

A single-component, composition technology, applied in the direction of polyurea/polyurethane coatings, coatings, latex paints, etc., can solve the problem of no water-based single-component research, and achieve the effect of satisfying the performance of the coating film and satisfying the soft feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

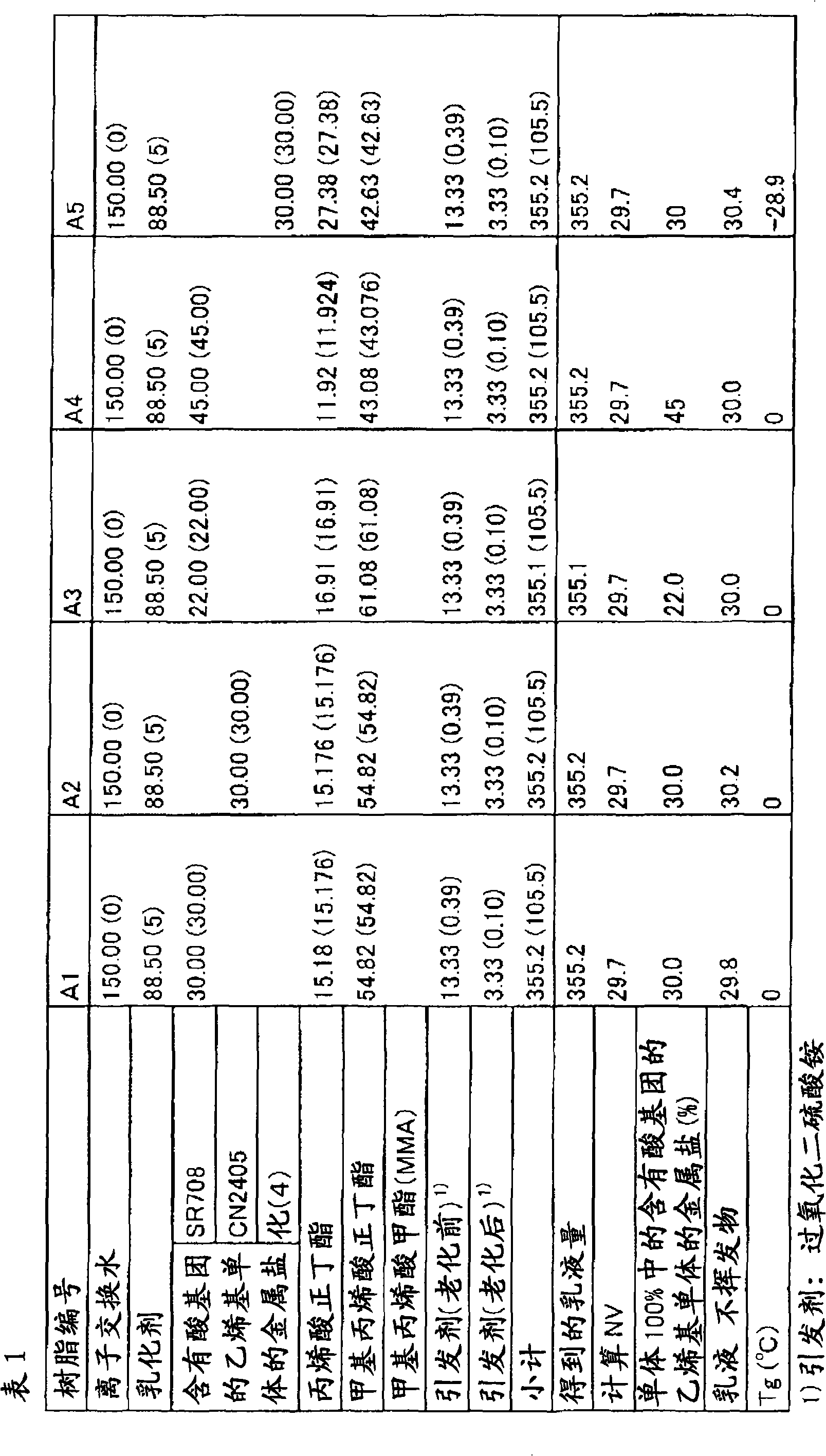

[0078] Add 67.11 g of acrylic emulsion (A1), 128.2 g of HUX561 (manufactured by Asahi Denka Co., Ltd.) as polyurethane dispersion (D), and 100.00 g of acid anhydride-modified chlorinated polyolefin resin emulsion (B2) to the container in this order After uniform dispersion, add 18.46 g of pigment paste DE-15070 (manufactured by Rohm & Haas), 3.00 g of ポリフイノーKL245 (manufactured by Kyoyoshi Chemical Co., Ltd.) as a leveling agent, and 104PA of Surfino as a defoamer. (manufactured by Aerodactus Co., Ltd.), 10.00 g of NMP (manufactured by Kuraray Co., Ltd.) as a film-forming auxiliary agent. Then, 60.00 g of resin particles P800T (manufactured by Negami Industry Co., Ltd.) (C1) was gradually added to the container and dispersed uniformly. 7.50 g of ASE-60 (manufactured by Rohm & Haas) and 25.00 g of ion-exchanged water were added as a thickener.

Embodiment 2~10、 comparative example 1~7

[0080] Change the ratio of materials as shown in Table 3, Table 4, and Table 5 respectively, and prepare in the same way as in Example 1 except that.

[0081]

[0082]

[0083]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com