Method of preparing environment friendly foam cotton

A manufacturing method and foam technology, applied in the foam field, can solve the problems of low industrial utilization value, environmental pollution, and incomparability, and achieve the effects of optimal industrial utilization value, reduced manufacturing cost, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Relevant present invention is to achieve above-mentioned purpose, adopts technique, means and its feature, effect, enumerates a preferred feasible embodiment hereby, and cooperates figure to describe in detail as follows:

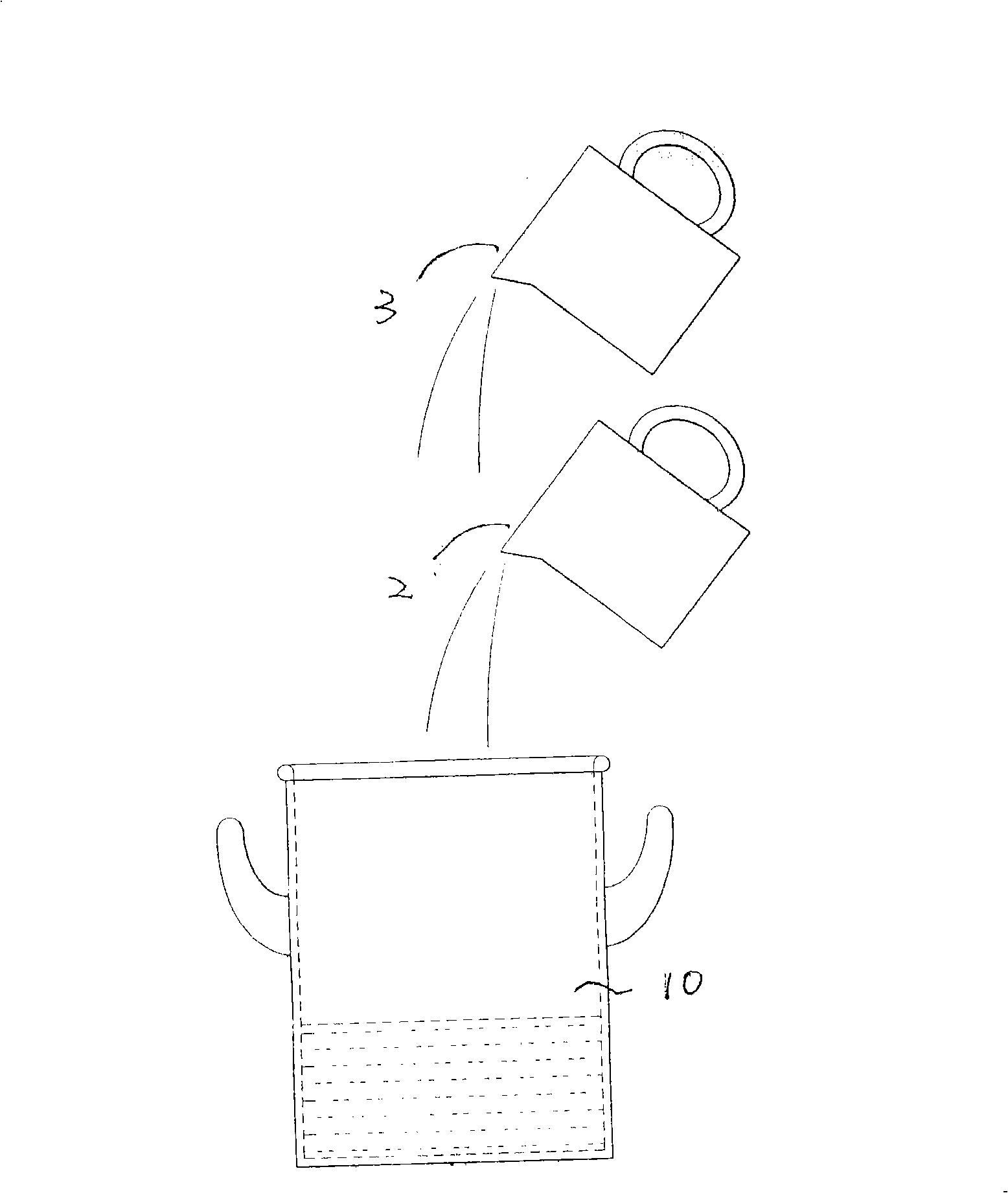

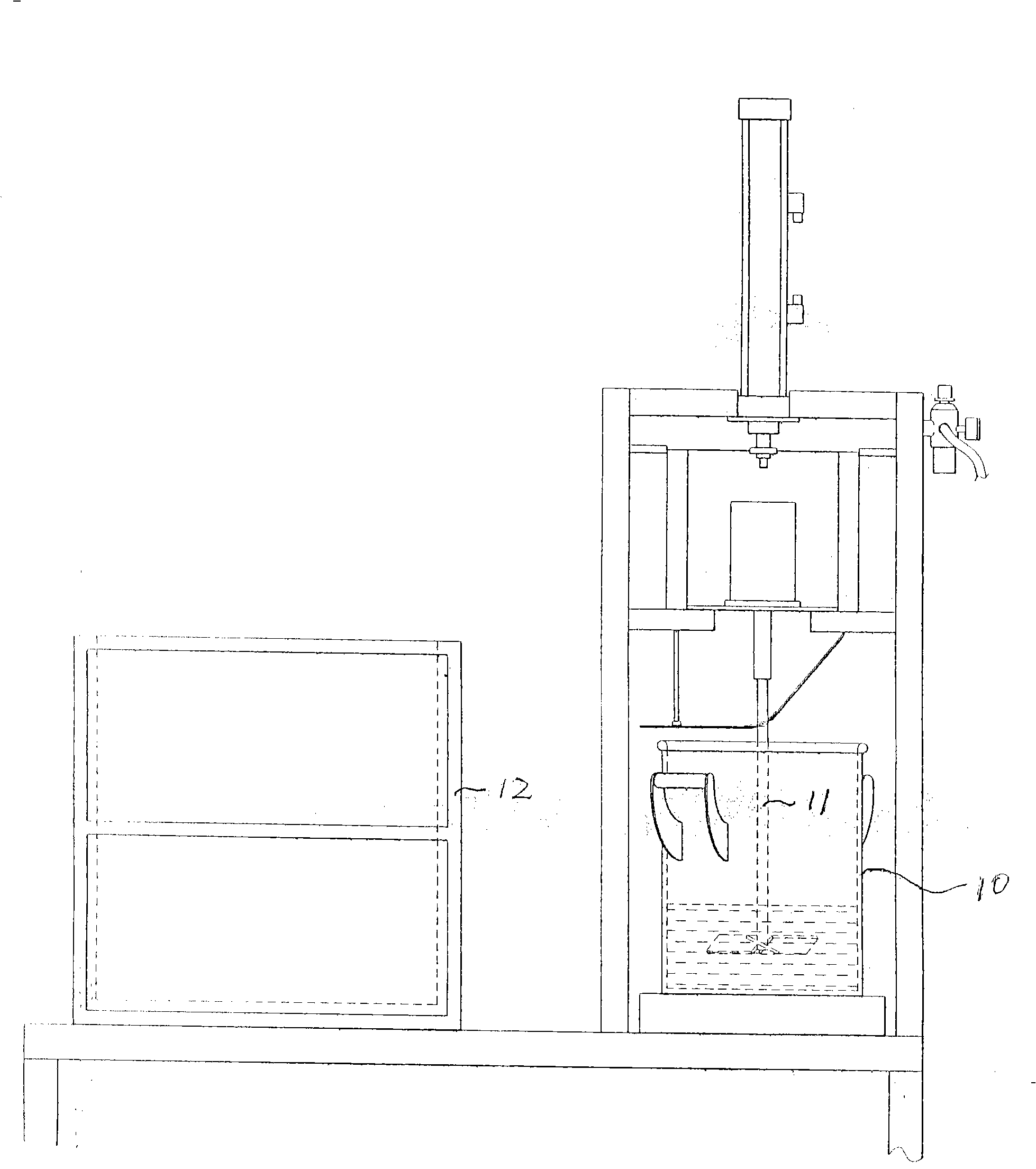

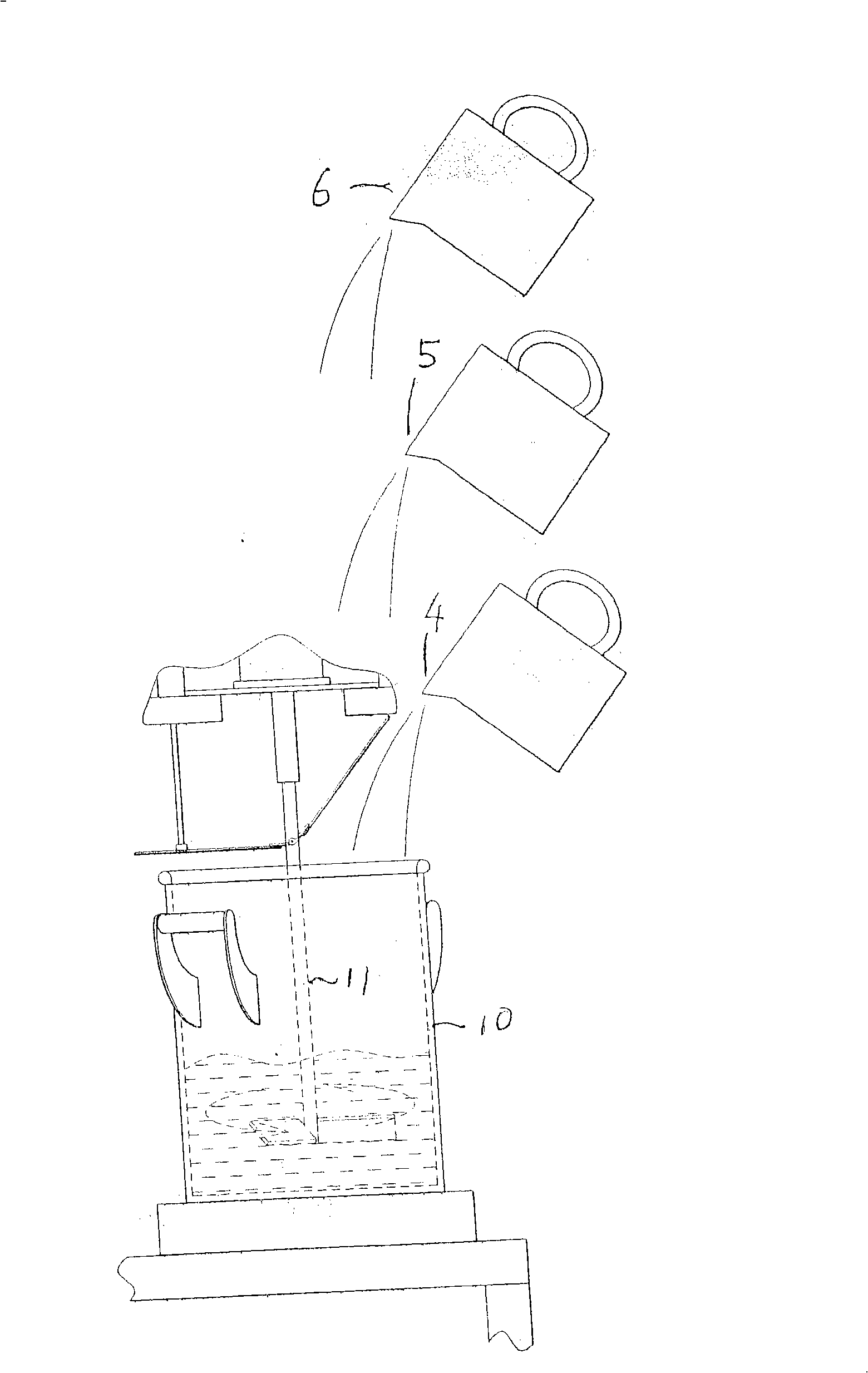

[0013] Please refer to figure 1 As shown, the basic steps of the embodiment of the environmental protection foam manufacturing method of the present invention can use an appropriate amount of container 10, and pour the mixed solution 3 of PPG polyether polyol 2 and MC dichloromethane and stannous zincate into it sequentially , so that the above foam basic raw materials are mixed, and then refer to figure 2 As shown, a stirring device 11 is used to stir the above-mentioned mixed raw materials to make them fully mixed. The recycled foam material used in the present invention can be made of foam residue or waste by machine crushing into fine particles or powder. The foam is crushed to a particle size of 0.05mm, 0.08mm, 0.10mm, 0.15mm, 0.2mm, 0.5mm, 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com