Method for reducing content of kalium and sodium in vanadium solvent extraction circulation liquid

A technology of circulating liquid and sodium content, which is applied in the field of sodium content and reducing potassium in the circulating liquid for vanadium extraction and leaching, which can solve the problems of reducing potassium and sodium content, and the solution cannot be recycled, and achieve the effect of avoiding the problem of emission pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

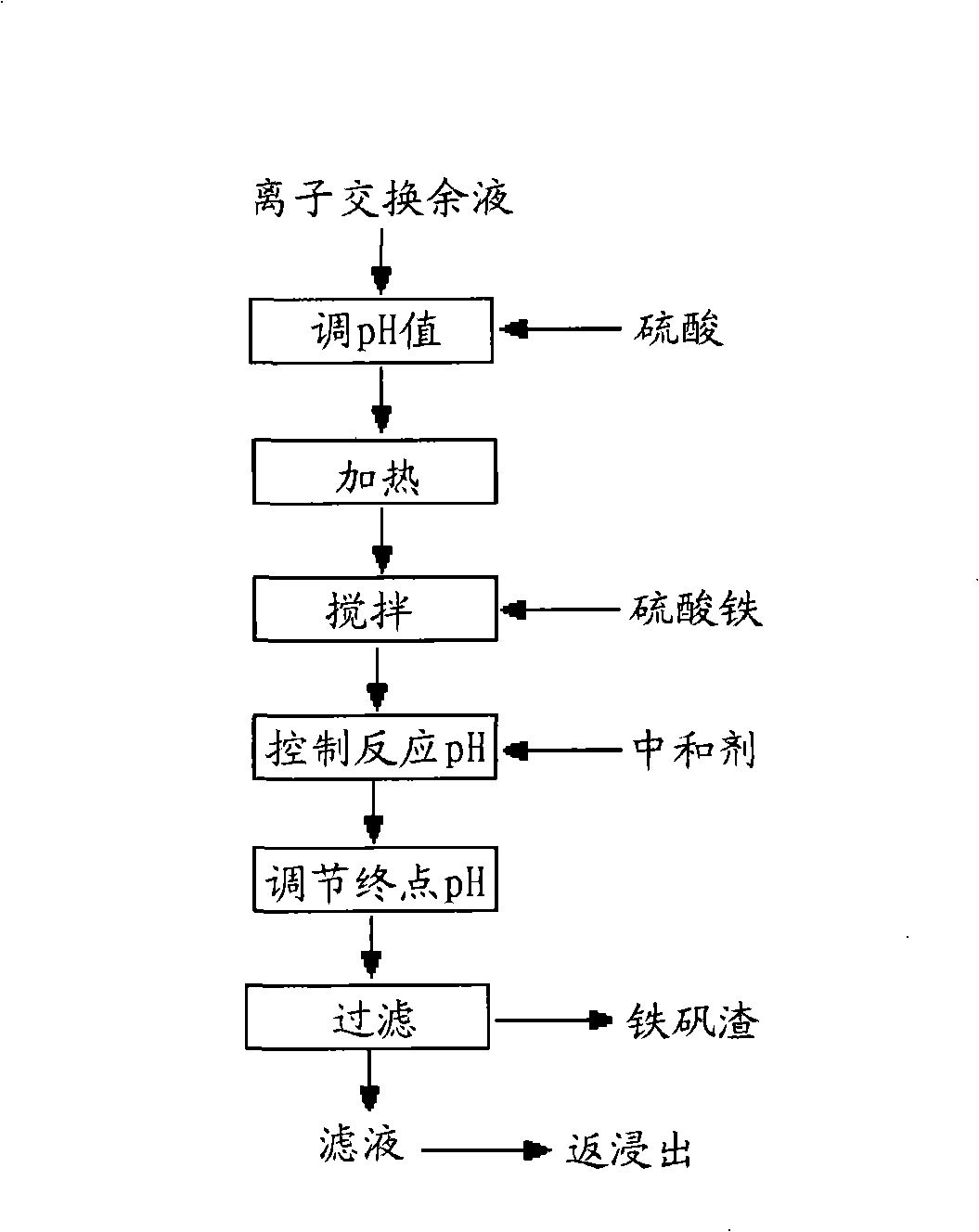

Method used

Image

Examples

example 1

[0023] Get the vanadium extraction leaching solution of 1200mL (the Na in the solution + The concentration is 20.7g / L, K + The concentration is 3.1g / L, SO 4 2- Concentration is 34.2g / L), adjust the pH value of the solution to 1.7 with concentrated sulfuric acid; water bath is heated to 95 ℃, add 580g ferric sulfate under the condition of stirring, and use calcium hydroxide to control the pH value of the solution at 1.4~ 1.9; after constant temperature reaction for 60 minutes, adjust the pH value of the solution to 3.8; filter to obtain 962 mL of filtrate. After analysis, the main components of the filtrate are: Na + The concentration is 2.4g / L, K + The concentration is 0.3g / L, SO 4 2- The concentration of 1.7g / L. The filtrate is returned to the leaching process for recycling.

example 2

[0025] Get the vanadium extraction leaching solution of 1600mL (the Na in the solution + The concentration is 34.5g / L, SO 4 2- Concentration is 53.1g / L), adjust the pH value of the solution to 2.2 with concentrated sulfuric acid; water bath is heated to 92 ℃, add 1290g iron sulfate under the condition of stirring, and use calcium hydroxide to control the pH value of the solution at 1.4~ 1.9; after constant temperature reaction for 120 minutes, adjust the pH value of the solution to 6.0; filter to obtain 1076 mL of filtrate. After analysis, the main components of the filtrate are: Na + The concentration is 2.7g / L, SO 4 2- The concentration of 0.3g / L. The filtrate is returned to the leaching process for recycling.

example 3

[0027] Get the vanadium extraction leaching solution of 2000mL (the Na in the solution + The concentration is 30.8g / L, SO 4 2- Concentration is 49.8g / L), adjust the pH value of the solution to 2.0 with concentrated sulfuric acid; water bath is heated to 95 ℃, add 1550g ferric sulfate under the condition of stirring, and use calcium hydroxide to control the pH value of the solution at 1.4~ 1.9; after constant temperature reaction for 90 minutes, adjust the pH value of the solution to 4.0; filter to obtain 1320 mL of filtrate. After analysis, the main components of the filtrate are: Na + The concentration is 2.5g / L, SO 4 2- The concentration of 1.5g / L. The filtrate is returned to the leaching process for recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com