Processing method for improving anti-torsion ability of shockproof lining

A treatment method and anti-torsion technology, applied to springs/shock absorbers, springs made of plastic materials, mechanical equipment, etc., can solve problems such as loss of shock-proof effect of shock-proof bushings, damage to the internal structure of rubber, and cracking at joints, etc. , to achieve the effect of enhanced anti-torsion ability, improved service life and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

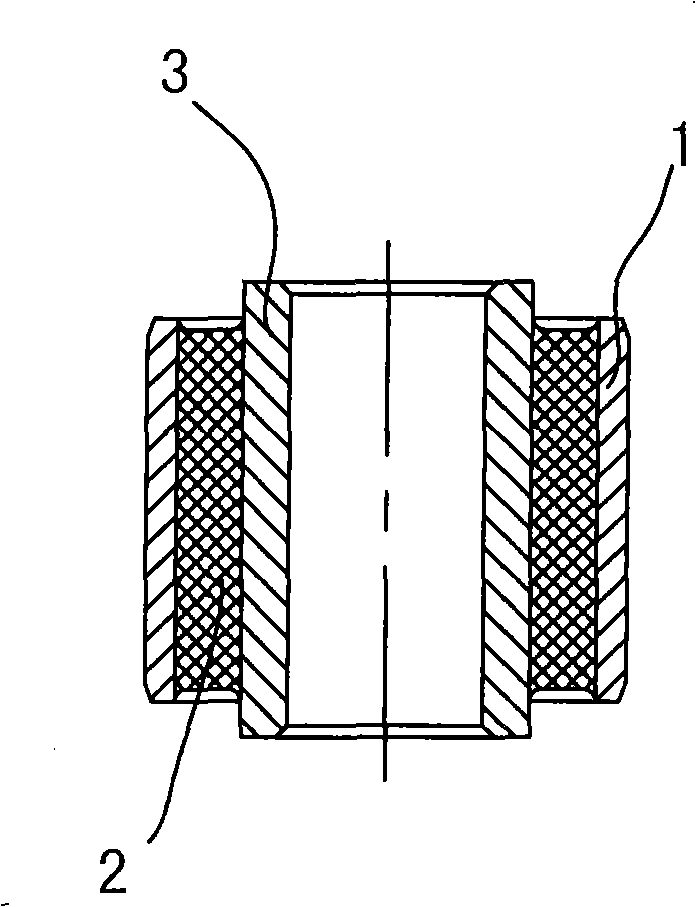

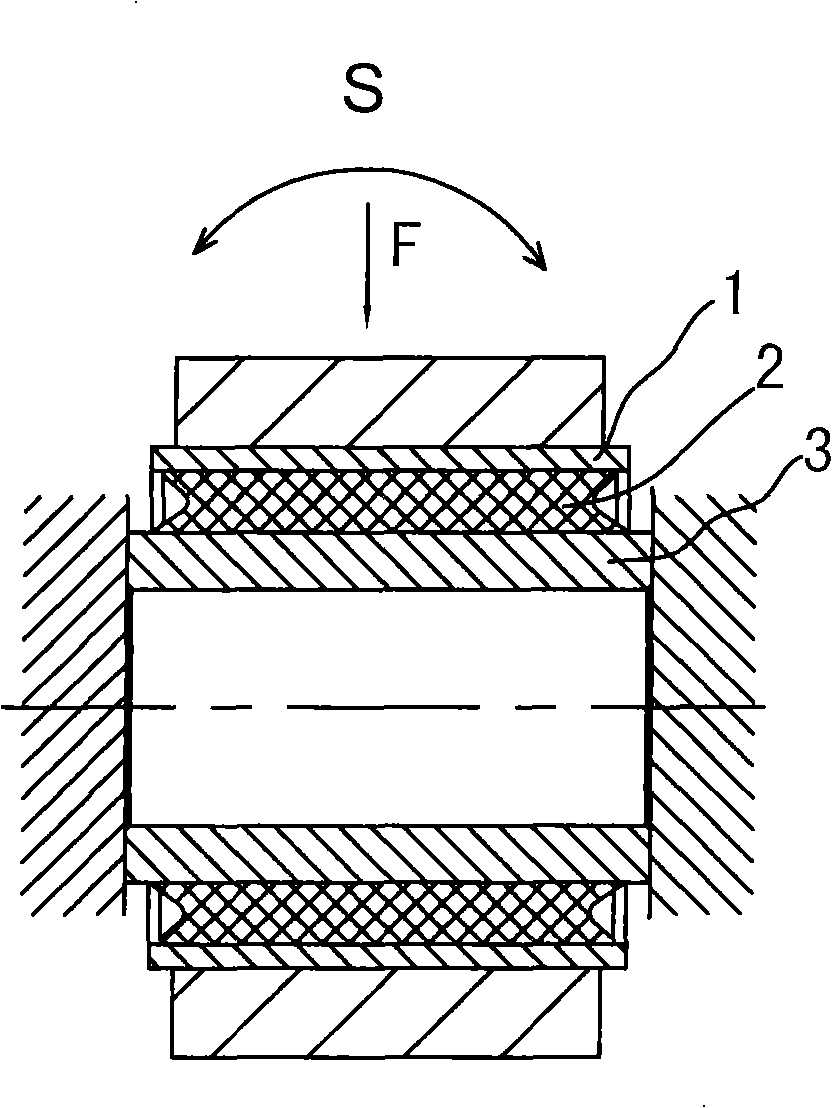

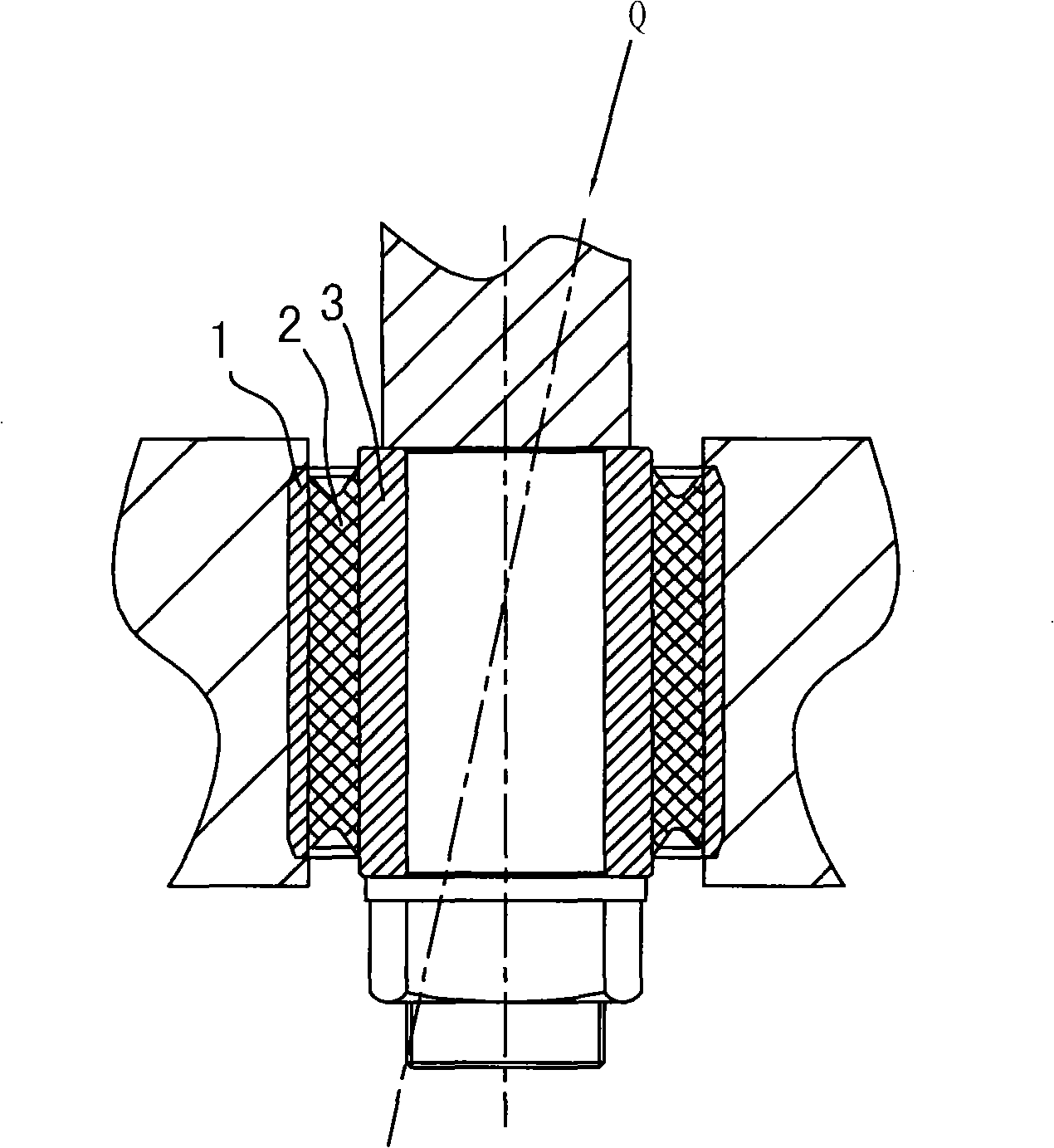

[0029] A treatment method for improving the torsion resistance of the anti-vibration bushing, such as figure 1 , as shown in Figure 4, for the anti-shock bushing connected by the rubber layer 2 to the inner metal sheath 3 and the outer metal sheath 1, the outer metal sheath 1 and the inner metal sheath 3 are first subjected to surface sandblasting and chemical treatment; and the processed The outer metal sheath 1 and the inner metal sheath 3 are fixed in position, and the rubber is injected into the cavity formed by the inner metal sheath 3 and the outer metal sheath 1. After the rubber is vulcanized and cooled, a rubber layer 2 is formed, so that the outer metal sheath 1 and the inner metal sheath 3 is integrated with the rubber layer 2; after the rubber vulcanization molding process, the outer circle of the outer metal sleeve 1 is roughly ground, and after rough grinding, the outer diameter of the outer metal sleeve 1 is subjected to radial compression treatment, which can en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com