High voltage metal-oxide-semiconductor transistor and manufacturing method thereof

A technology of oxide semiconductors and manufacturing methods, which is applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of unfavorable integrated circuit component size reduction and integration improvement, increase component area, etc., and reduce the surface area. Effects of electric field, increased current path, and improved breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

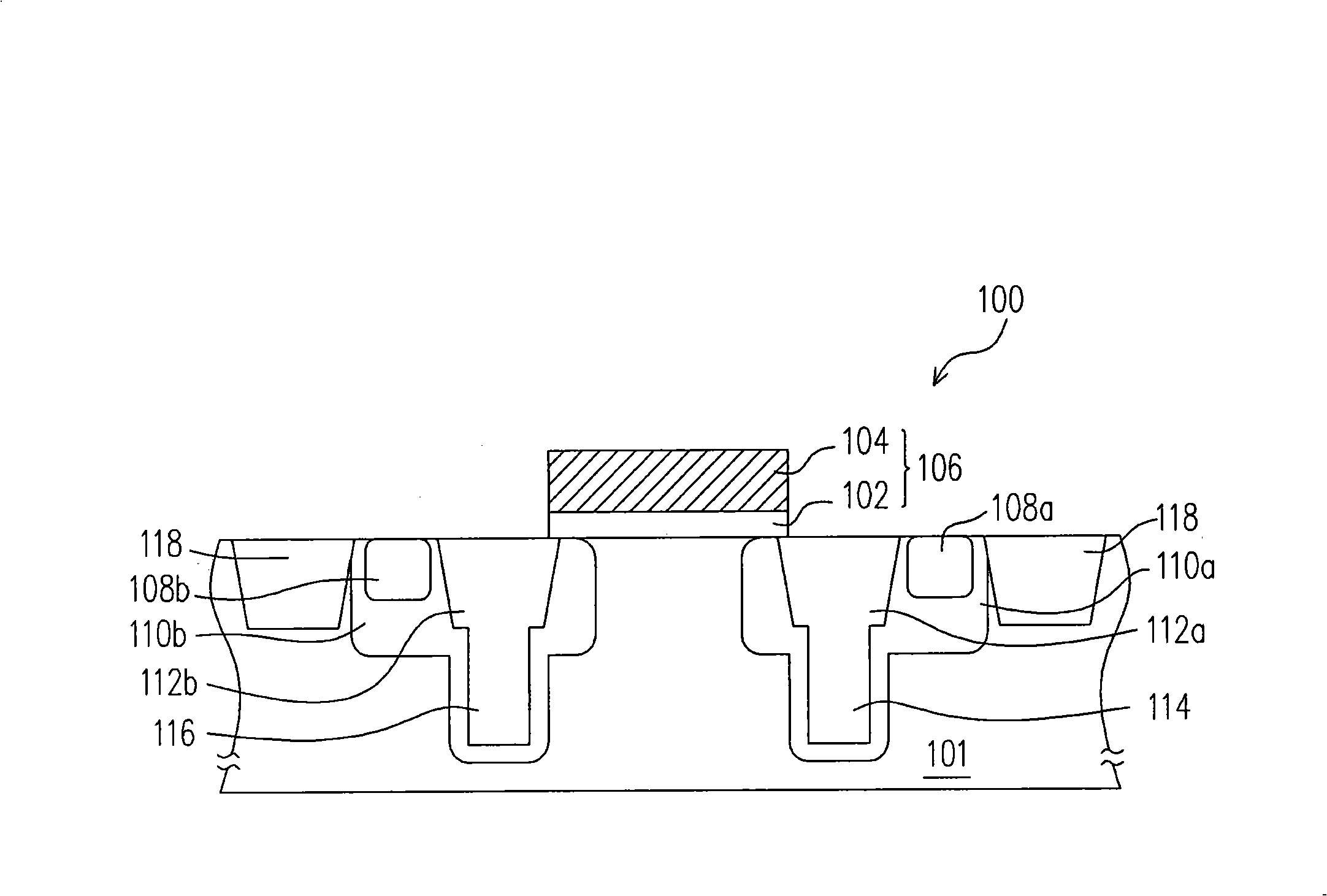

[0047] figure 1 It is a schematic cross-sectional view of a high-voltage metal-oxide-semiconductor transistor according to an embodiment of the present invention.

[0048] Please refer to figure 1 , the high-voltage metal oxide semiconductor transistor 100 of this embodiment includes a first-type doped substrate 101, a gate structure 106, a second-type drain region 108a, a second-type source region 108b, and second-type drift regions 110a and 110b , the first isolation structures 112 a and 112 b and the second isolation structures 114 and 116 .

[0049] The first-type doped substrate 101 is, for example, a well region or an epitaxial layer, and the first-type doped substrate 101 has two element isolation structures 118 . The first isolation structures 112a and 112b are respectively disposed in the first-type doped substrate 101 . The first isolation structures 112a and 112b are, for example, shallow trench isolation (STI). The material of the first isolation structures 112...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com