Method for producing upper gear tooth of steering arm shaft of automotive power steering gear

A technology of power steering gear and manufacturing method, which is applied in the direction of metal processing equipment, etc., and can solve the problems of low strength of gear teeth 12, sticking of knives, large cutting volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

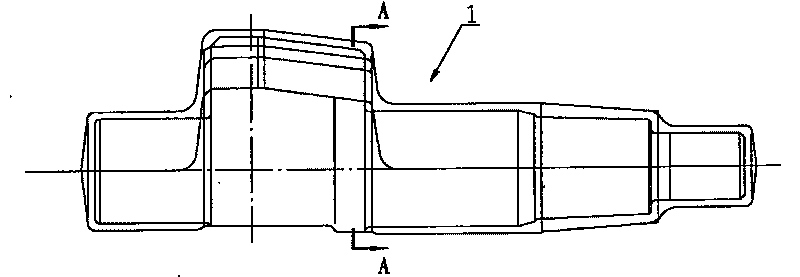

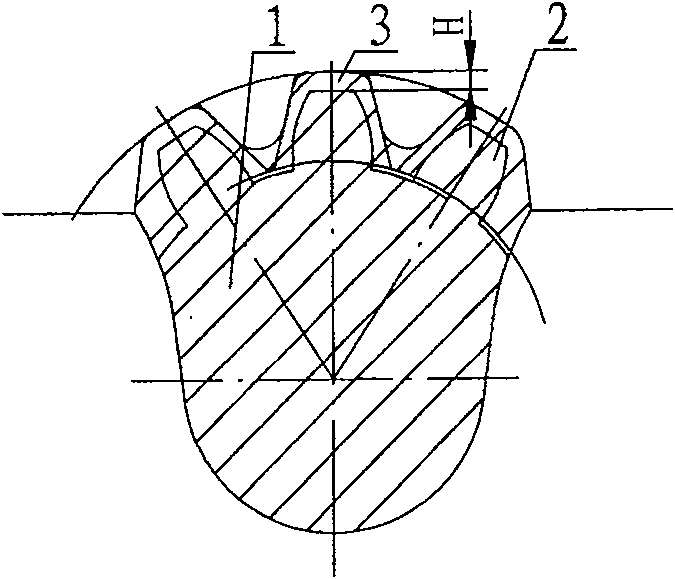

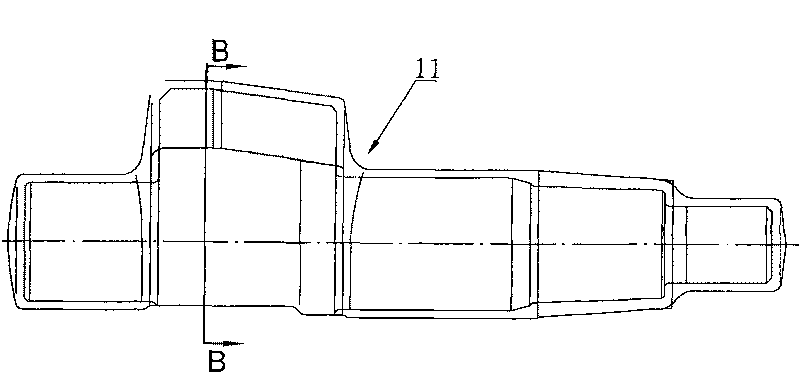

[0022] refer to figure 1 and figure 2 , the manufacturing method of the gear teeth on the steering arm shaft of the automobile power steering gear of the present invention, the forging die includes an initial forging die and a final forging die for blank making, and the initial forging die is designed according to the structure of the steering arm shaft forging blank ; The final forging die is designed according to the structure of the finished product of the steering arm shaft. Gear teeth are formed on the shaft body of the steering arm shaft using a forging die through the following process.

[0023] Metal billet heating and initial forging: Heating the metal billet to 1200°C and putting it into the billet mold of the forging die, and reasonably distributing the volume of the billet through forging (making the cross-sectional area of the billet along the axis roughly compatible with the forging) to obtain the forging of the steering arm shaft Blank.

[0024] Steering ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com