Elevator drawing belt and transmission method thereof

An elevator traction and traction belt technology, which is applied to elevators, elevators in buildings, textile cables, etc., can solve the problems of imperfect flat traction belt structure, and achieve a feasible transmission method, reasonable structure design, and reduced The effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

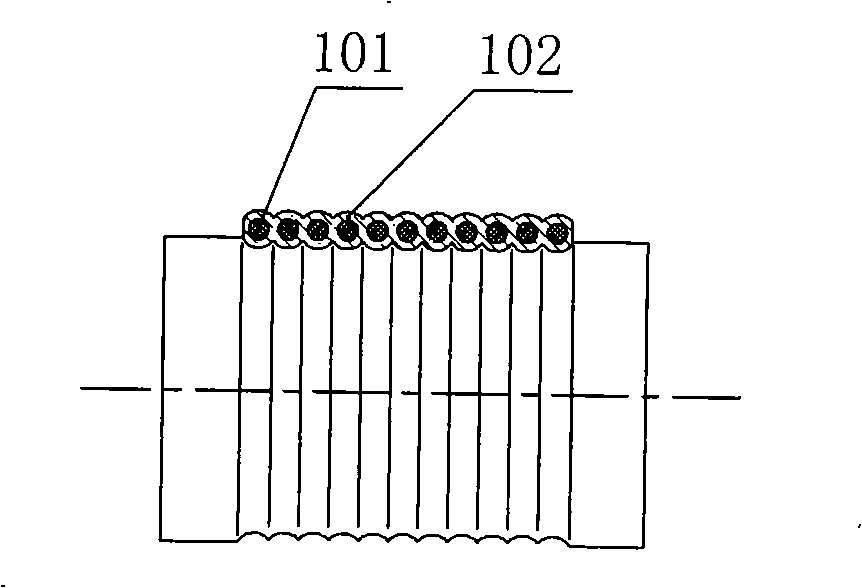

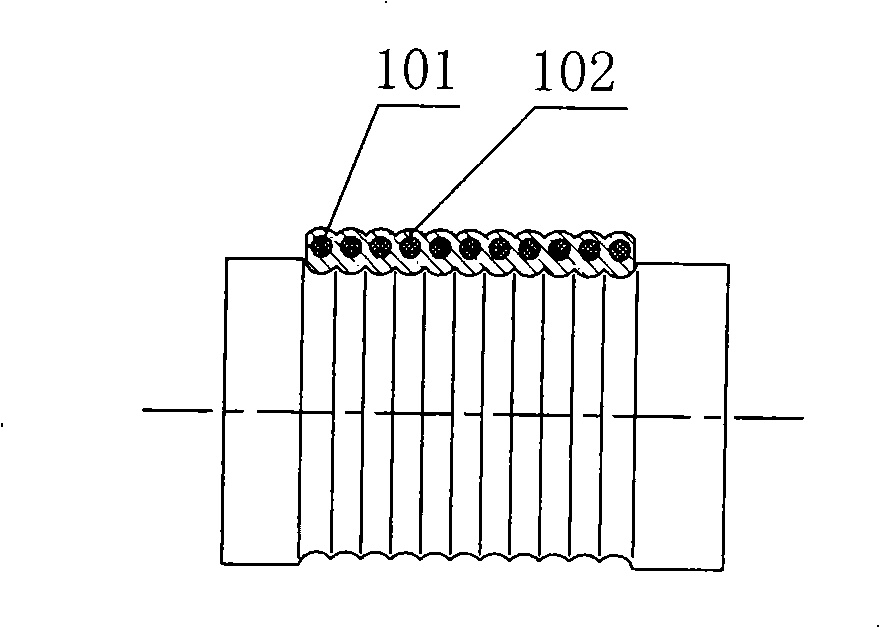

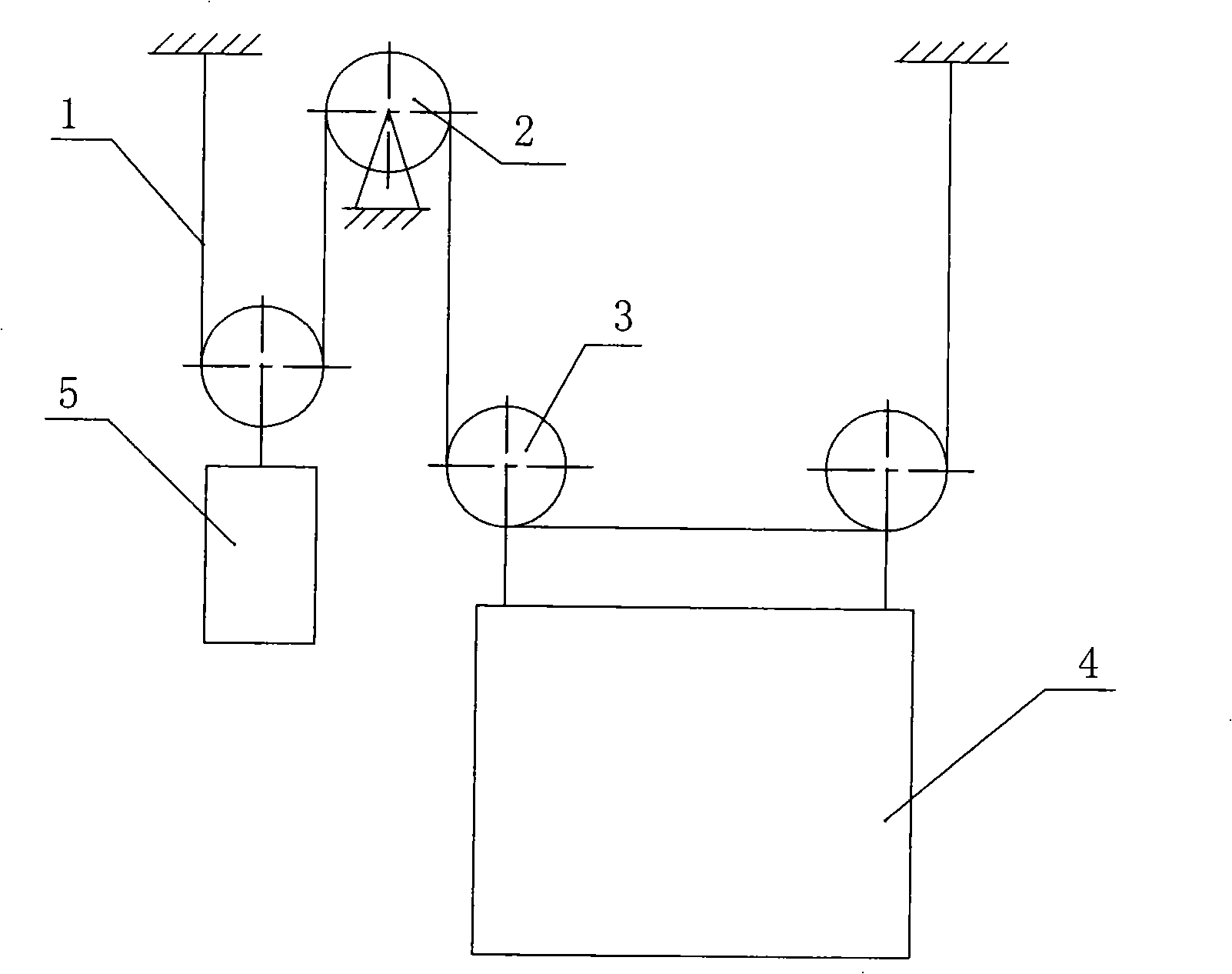

[0019] The implementation mode takes the working principle and assembly of the present invention as an example. like figure 1 , figure 2 As shown, the traction belt is composed of multi-strand steel wire ropes 101 coated with rubber and plastic materials 102 . The steel wire rope is woven by twisted high-strength thin steel wires, and multiple steel wire ropes are arranged equidistantly in the traction belt; the outer rubber and plastic material has the characteristics of high wear resistance and high friction coefficient, and its outer two sides are symmetrical. An arc with a radius greater than 50% of the spacing between the wire ropes. like image 3 As shown, one end of the traction belt is fixed, through two (or one) guide wheels 3, through the traction sheave 211 of the traction machine 2, through another guide wheel, and finally the other end of the traction belt is fixed. The guide wheel on one side of the traction machine hangs the counterweight 5, and the guide w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com