Controller capable of inhibiting mechanical impact of revolving furnace body

A mechanical shock and controller technology, applied in electric controllers, rotary drum furnaces, comprehensive factory control, etc., can solve the problems of the system not running well and stably, serious mechanical shock, loss of network technology advantages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

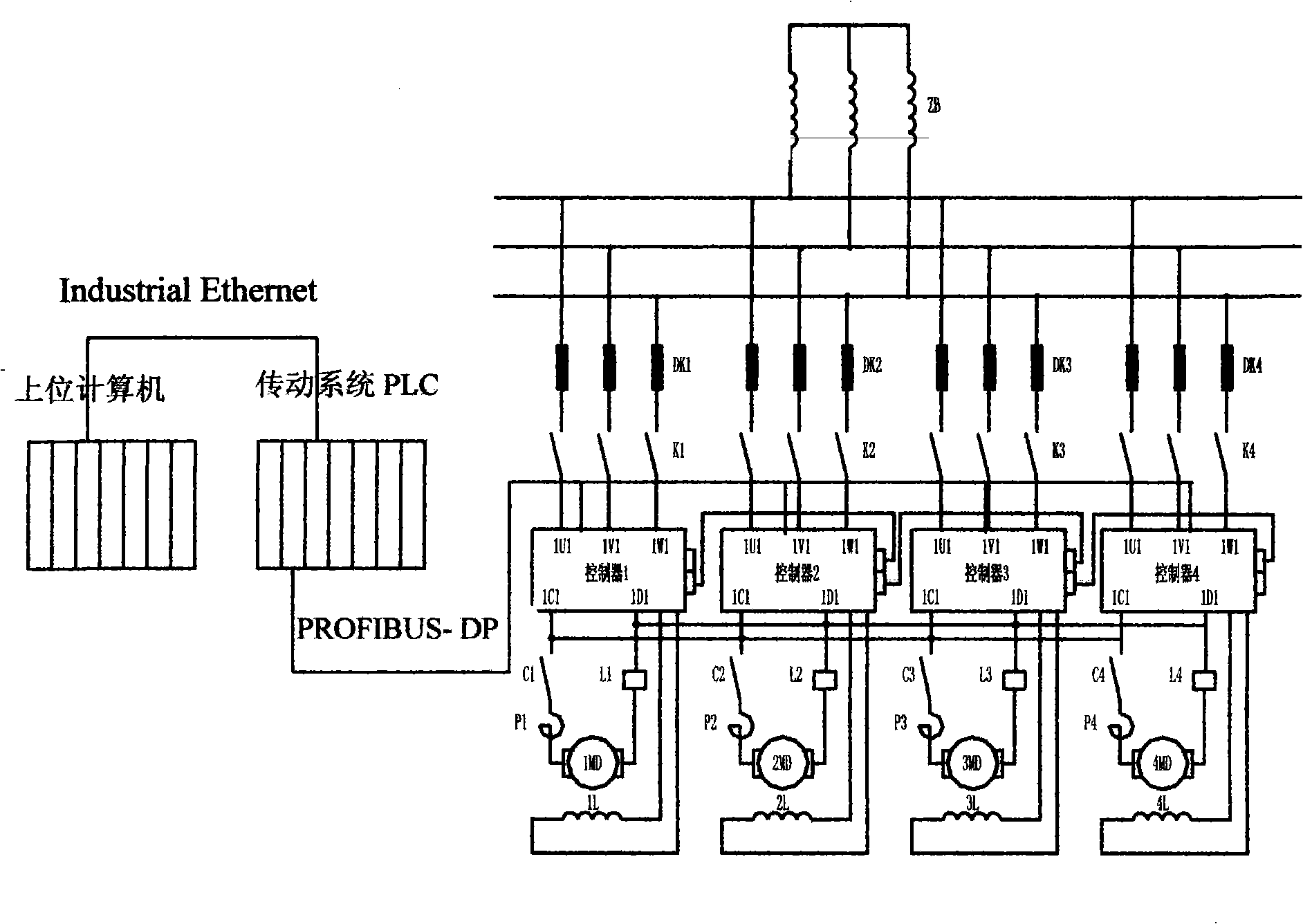

[0010] The controller capable of suppressing the mechanical impact of the converter body in the present invention is realized in this way, and will be described in detail below in conjunction with the accompanying drawings. See figure 1 , a controller that can suppress the mechanical impact of the converter body, it is for four motors used for converter tilting, four transmission control devices are selected, the DC main circuit output ends of the four devices are connected in parallel first, and then the four motors are controlled; One of the four devices is set as the master control device, and the other three are set as slave control devices. The master control device has its own voltage loop and current loop, and the control pulse phase angle of the slave control device is taken from the master control pulse.

[0011] The transmission device and the device are connected through the CUD2 expansion unit with 8-pin shielded cable UTPCAT5, connected according to ANS1 / TIA 568, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com