Capacitor and manufacturing method thereof

A manufacturing method and capacitor technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, circuits, etc., can solve the problems of limited manufacturing space size, difficulty in integrating capacitors, high process temperature and process execution time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

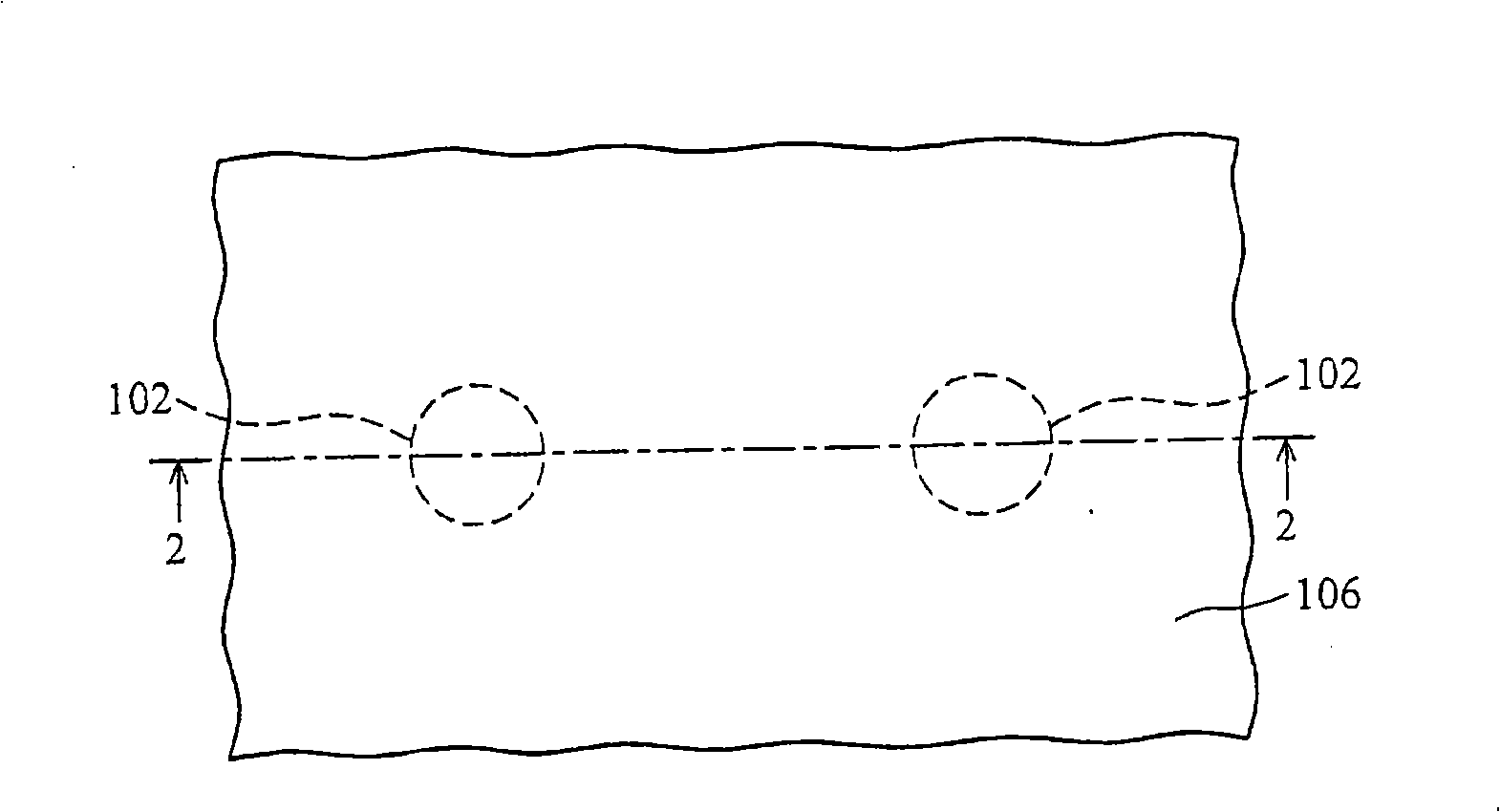

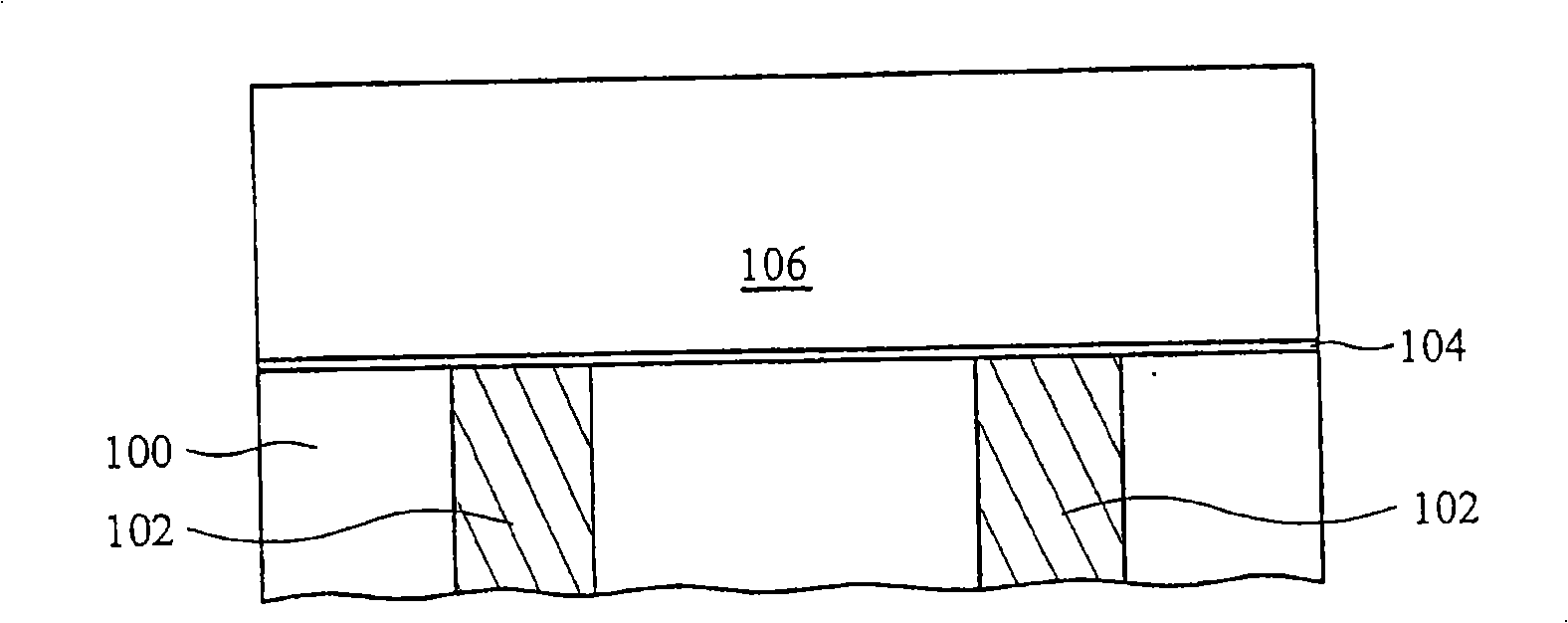

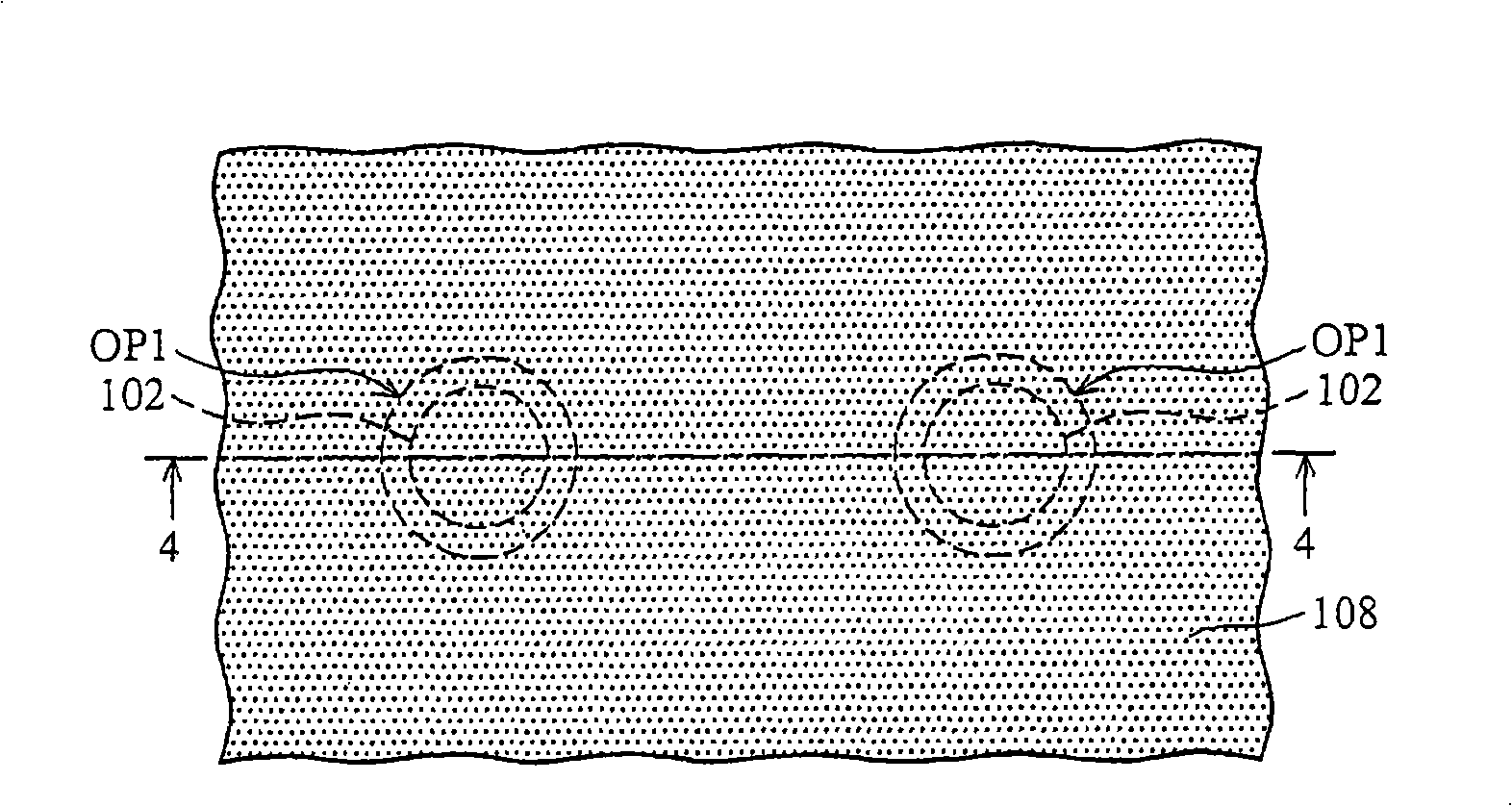

[0029] The embodiment of the capacitor and its manufacturing method of the present invention will cooperate with the following and Figure 1-12 Exemplified by the scheme of figure 1 , 3 , 5, 7, 9 and 11 are a series of top view diagrams, and figure 2 , 4 , 6, 8, 10 and 12 are a series of schematic cross-sectional diagrams, which respectively show the figure 1 , 3 The cross-sections of the line segments 2-2, 4-4, 6-6, 8-8, 10-10, and 12-12 in 5, 7, 9, and 11 are used to explain the production in different steps.

[0030] Please also refer to figure 1 versus figure 2 First, a semiconductor structure is provided. The semiconductor structure includes a pair of conductive contacts 102 disposed in the dielectric layer 100. Here, the semiconductor structure may further include a semiconductor substrate (not shown) and a plurality of transistors (not shown) formed on the semiconductor substrate, and the conductive contacts 102 respectively electrically contact one of the transistors p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com