Process for producing glass substrate for magnetic disk and process for manufacturing magnetic disk

一种玻璃衬底、制造方法的技术,应用在制造基底层、唱片载体制造等方向,达到抑制微小波纹、防止热不均匀、防止磁头碰撞的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0126] Hereinafter, it demonstrates concretely by giving an Example and a comparative example. In addition, this invention is not limited to the structure of these Examples.

[0127] [Example of Manufacturing Method of Glass Substrate for Magnetic Disk]

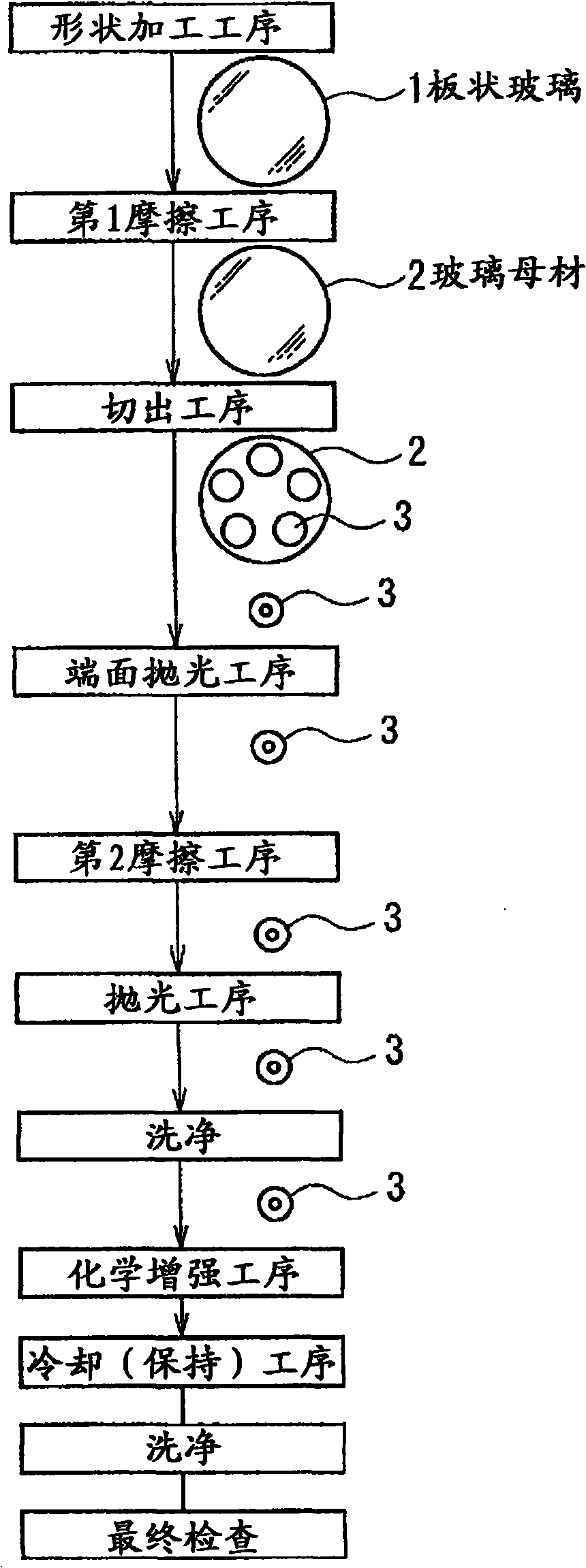

[0128] The manufacturing method of the glass substrate for magnetic disks in this embodiment described below consists of the following steps (1) to (9).

[0129] (1) Rough friction process (rough grinding process)

[0130] (2) Shape processing process

[0131] (3) Fine friction process (finish grinding process)

[0132] (4) End mirror processing (polishing) process

[0133] (5) The first grinding (polishing) process

[0134] (6) The second grinding (polishing) process

[0135] (7) Chemical enhancement process

[0136] (8) Cooling process

[0137] (9) Cleaning process

[0138] First, a disk-shaped glass base material made of amorphous aluminosilicate glass is prepared. This aluminosilicate glass contains lithium. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com